Device and method for continuous recovery and utilization of energy in drilling process

A technology of energy recovery and energy, which is applied to drilling equipment and methods, electromechanical devices, percussion drilling, etc., can solve the problems of low utilization efficiency, waste and consumption of gravitational potential energy, and achieve high-efficiency utilization, reduced loss, and reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

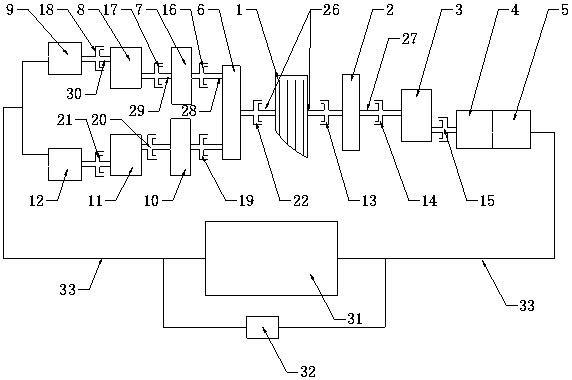

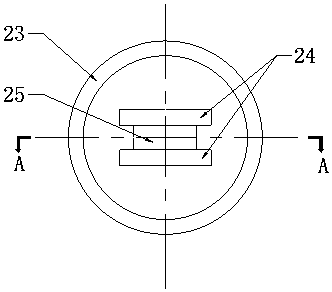

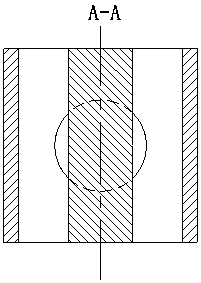

[0046] combined with figure 1 As shown, during conventional drilling, the tenth clutch 22 and the second clutch 14 are first disconnected, the first clutch 13 is in a closed state, and the central shaft 26 of the drawworks 1 rotates with the lowering of the drill pipe to drive the first spring for energy storage. The energy storage device 2 is used for energy storage. In the state of decompression drilling, the first clockwork accumulator 2 provides a certain load for decompression drilling, reducing the working load of the drilling rig equipment. After the energy stored in the first clockwork accumulator 2 is saturated, the first clutch 13 is disconnected, the second clutch 14 and the third clutch 15 are closed, and the first clockwork accumulator 2 releases mechanical energy to drive the first gearbox 3 to rotate. The first gearbox 3 provides initial kinetic energy for the rotation of the rotor 24 of the driver 4, thereby driving the first generator 5 to generate electricity...

example 2

[0048] combined with figure 1 As shown, when the drill pipe is continuously lowered, the first clutch 13 is in a disengaged state, and the first generator 5 relies on the energy stored in the first clockwork accumulator 2 to continue to work. The tenth clutch 22 is in the closed state, the fourth clutch 16 is closed, and the seventh clutch 19 is disconnected. The winch 1 first drives the second clockwork accumulator 7 for energy storage. After the energy storage is saturated, refer to the operation steps of Example 1 to drive The second generator 9 works. At this time, the seventh clutch 19 is closed, the fourth clutch 16 is disconnected, and the third generator set repeats the operation process of the second generator set to generate electricity. During the continuous lowering of the drill pipe, the second generator set and the third generator set work alternately in order to ensure continuous power generation of the generator. Part of the electric energy generated by the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com