Novel pipeline electric heater

A pipeline electric heater, a new type of technology, applied in the ohmic resistance heating parts, the shape of the heating element, the ohmic resistance waterproof/airtight and other directions, which can solve the problem that the insulating silica gel is easily damaged and falls off, increasing the risk of electric shock to users, and leakage of terminals. problems, to improve the firmness and sealing, not easy to fall off and leakage, and increase the connection length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

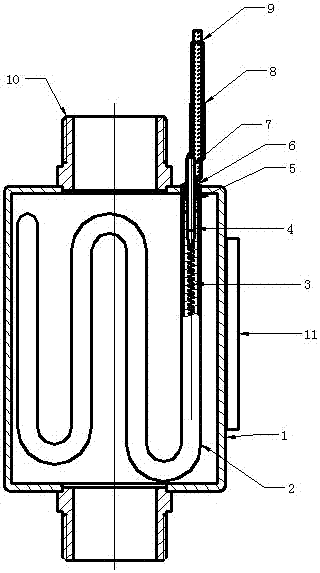

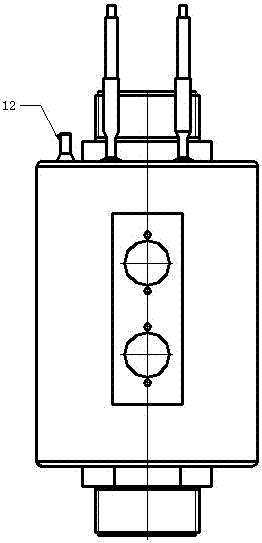

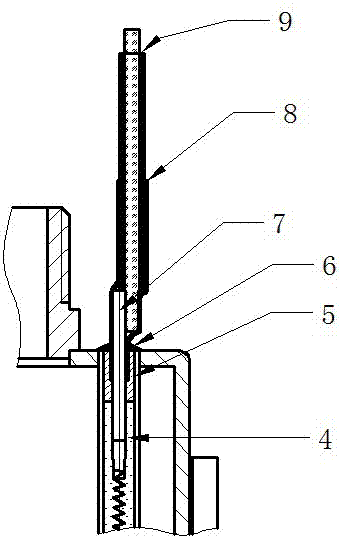

[0018] as attached Figure 1-2 As shown, a new pipeline electric heater includes cylinder body 1, heating tube 2, resistance wire 3, magnesium oxide powder filler 4, AB glue 5, silica gel 6, terminal post 7, heat shrinkable tube 8, power cord 9 , joint 10, ground wire screw 11 and thermostat connecting plate 12; the cylinder body 1 is made of stainless steel, with joints 10 arranged at its two ends, ground wire screw 11 arranged on the top surface, and a thermostat for installing the thermostat is welded externally. The controller connection plate 12, the coil heating tube 2 is arranged in the cylinder body 1, the two ends of the heating tube 2 extend to the top of the cylinder body 1, and one end is fixed to the top surface of the cylinder body 1; the heating tube 2 is filled with magnesium oxide powder Filler 4, magnesia powder filler 4 is embedded with resistance wire 3, the top of resistance wire 3 is connected to terminal 7, one end of terminal 7 is embedded in magnesia p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com