Fabrication method of low-PIM and high-performance microwave high-frequency composite ceramic substrate

A composite ceramic, high-performance technology, applied in high-frequency matching devices, circuit substrate materials, printed circuit manufacturing, etc., can solve problems that plague radio frequency and microwave communication systems, and achieve low intermodulation interference, excellent mechanical strength, and excellent signal simulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

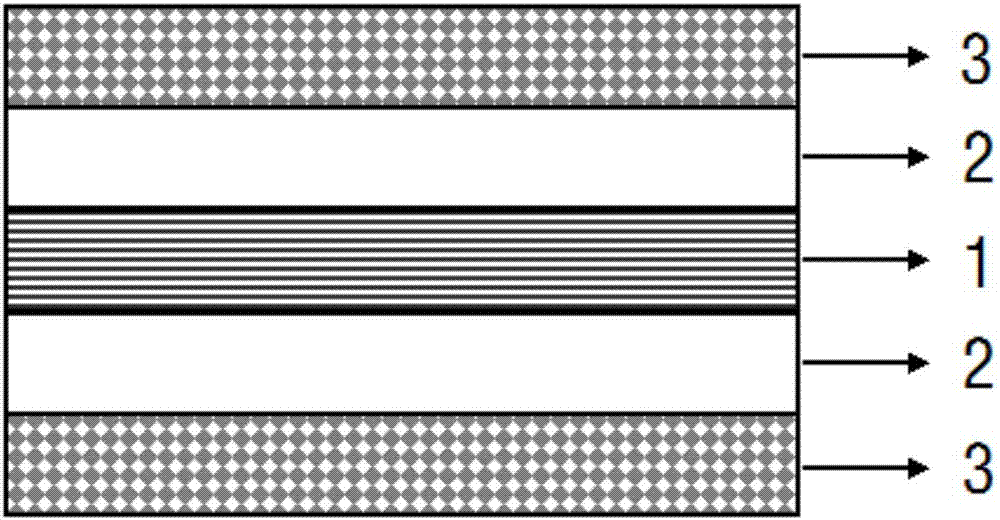

[0020] A1. To make microwave high-frequency ceramic insulating dielectric material layer 1, mix polytetrafluoroethylene powder and low-temperature co-fired ceramic powder at a ratio of 1:1, and form a dielectric material through a ball mill for 25 hours, and then place the dielectric material in a mold for 300 hours. ~320°C high-temperature pressing to form microwave high-frequency ceramic insulating dielectric material layer 1;

[0021] A2. To make low-PIM ceramic bonding sheet 2, select a low-temperature ceramic sheet with a thickness of 8.4 μm and put it into the polytetrafluoroethylene dispersion liquid for pre-impregnation with a dipping machine, and then sinter at a high temperature of 300-320°C to obtain a low-PIM ceramic bonding sheet. Knot 2;

[0022] A3. To make a low-PIM high-performance microwave high-frequency composite ceramic substrate, select a matt copper foil 3 with a surface roughness of 0.09 μm and a thickness of 35 μm, and place the matt copper foil 3 abov...

Embodiment example 2

[0024] B1. To make microwave high-frequency ceramic insulating dielectric material layer 1, mix polytetrafluoroethylene powder and low-temperature co-fired ceramic powder at a ratio of 1:3, and form a dielectric material through a ball mill for 35 hours, and then place the dielectric material in a mold for 300 hours. ~320°C high-temperature pressing to form microwave high-frequency ceramic insulating dielectric material layer 1;

[0025] B2. To make low-PIM ceramic bonding sheet 2, select a low-temperature ceramic sheet with a thickness of 8 μm and put it into the polytetrafluoroethylene dispersion liquid for pre-impregnation with a dipping machine, and then sinter at a high temperature of 300-320°C to obtain a low-PIM ceramic bonding slice 2;

[0026] B3. To make a low-PIM high-performance microwave high-frequency composite ceramic substrate, select a matt copper foil 3 with a surface roughness of 0.08 μm and a thickness of 280 μm, and place the matt copper foil 3 above and b...

Embodiment example 3

[0028] C1. To make microwave high-frequency ceramic insulating dielectric material layer 1, mix polytetrafluoroethylene powder and low-temperature co-fired ceramic powder at a ratio of 3:7, and form a dielectric material through a ball mill for 30 hours, and then place the dielectric material in a mold for 300 hours. ~320°C high-temperature pressing to form microwave high-frequency ceramic insulating dielectric material layer 1;

[0029] C2. To make low-PIM ceramic bonding sheet 2, select a low-temperature ceramic sheet with a thickness of 7.8 μm and put it into the polytetrafluoroethylene dispersion liquid for pre-impregnation with a dipping machine, and then sinter at a high temperature of 300-320°C to obtain a low-PIM ceramic bonding sheet. Knot 2;

[0030] C3. To make a low-PIM high-performance microwave high-frequency composite ceramic substrate, select a matt copper foil 3 with a surface roughness of 0.085 μm and a thickness of 60 μm, and place the matt copper foil 3 abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com