Rubidium-containing bone cement and preparation method and application thereof

A technology of bone cement and rubidium salt, which is used in medical science, tissue regeneration, prosthesis, etc., can solve the problems of affecting stability and mechanical properties, high elastic modulus, interface micro-cracks, etc., and achieves good setting time and good plasticity. , the effect of accelerating the release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of the rubidium-containing bone cement described in the present embodiment comprises the following steps:

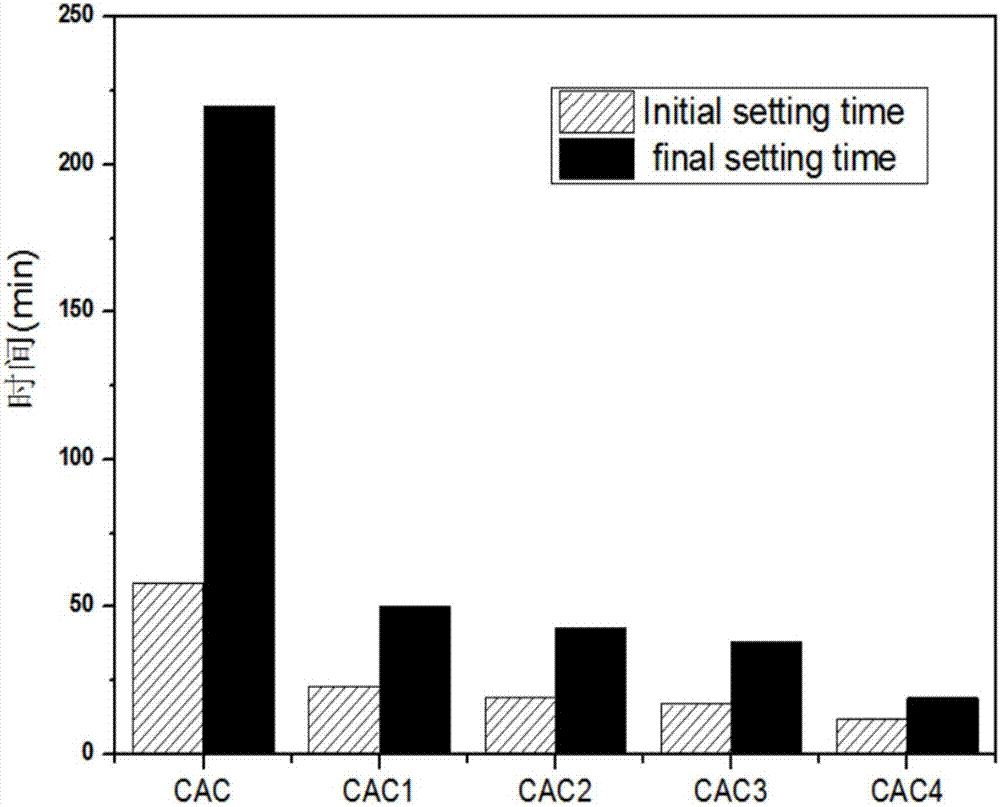

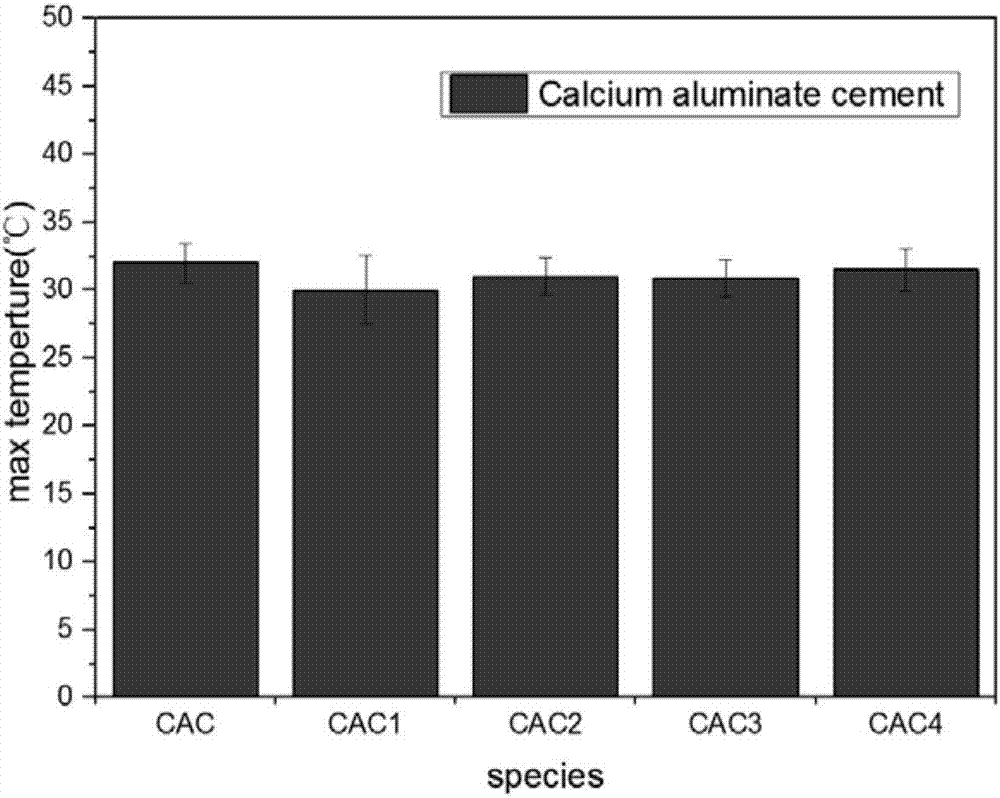

[0040] Put the ball-milled and sieved bone cement powder into the agate mortar for grinding again. According to the mass ratio of rubidium salt solution to calcium aluminate is 0.7:1, add 0mol / L rubidium salt solution (ultra-pure deionized water), and stir thoroughly After mixing, put it into a clean mold, put the mold in a 100% water bath environment with a constant temperature of 37 degrees, put the bone cement cylinder in a constant temperature box at 37 degrees Celsius, and let it stand for 1-21 days before demoulding to obtain the bone cement. Restoration materials.

Embodiment 2

[0042] The preparation method of bone cement described in the present embodiment comprises the steps:

[0043] The bone cement powder that had been ball-milled and sieved was put into an agate mortar for grinding again. According to the mass ratio of rubidium salt solution to calcium aluminate at 0.7:1, 0.01mol / L rubidium salt solution (ultra-pure deionized water) was added to fully After stirring and mixing, put it into a clean mold, put the mold in a 100% water bath environment at a constant temperature of 37°C, and place the bone cement cylinder in a constant temperature box at 37°C. After standing for 1-21 days, the bone cement will be removed from the mold. Cement repair material.

Embodiment 3

[0045] The preparation method of bone cement described in the present embodiment comprises the steps:

[0046] The bone cement powder that had been ball-milled and sieved was put into an agate mortar for grinding again. According to the mass ratio of rubidium salt solution to calcium aluminate at 0.7:1, 0.05mol / L rubidium salt solution (ultra-pure deionized water) was added to fully After stirring and mixing, put it into a clean mold, put the mold in a 100% water bath environment at a constant temperature of 37°C, and place the bone cement cylinder in a constant temperature box at 37°C. After standing for 1-21 days, the bone cement will be removed from the mold. Cement repair material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com