Manufacturing process of ceramic waterway faucet

A manufacturing process, faucet technology, applied in the direction of manufacturing tools, ceramic molding machines, valve details, etc., can solve the problems of ceramic faucets such as low service life, poor impact resistance, weak frost resistance, etc., to achieve good protection and prevent damage , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

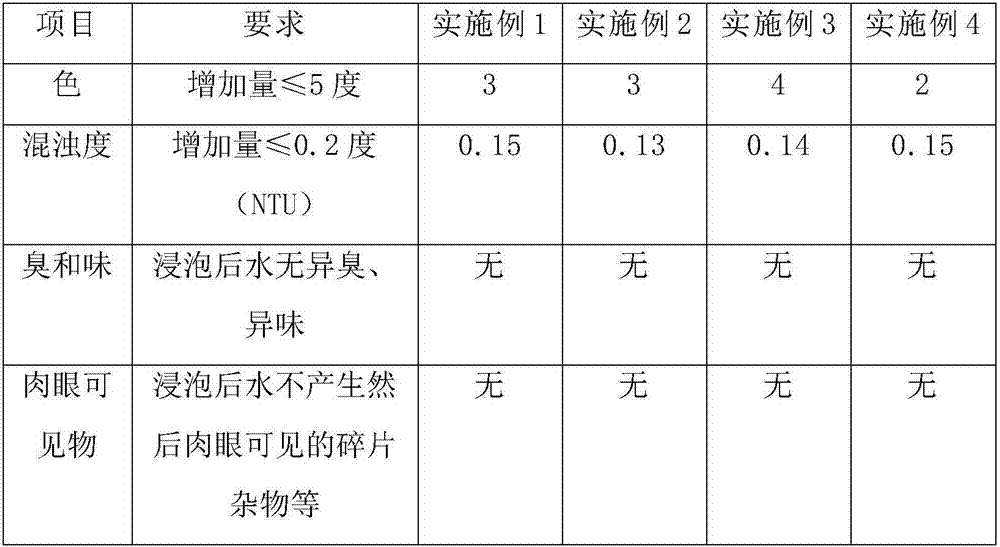

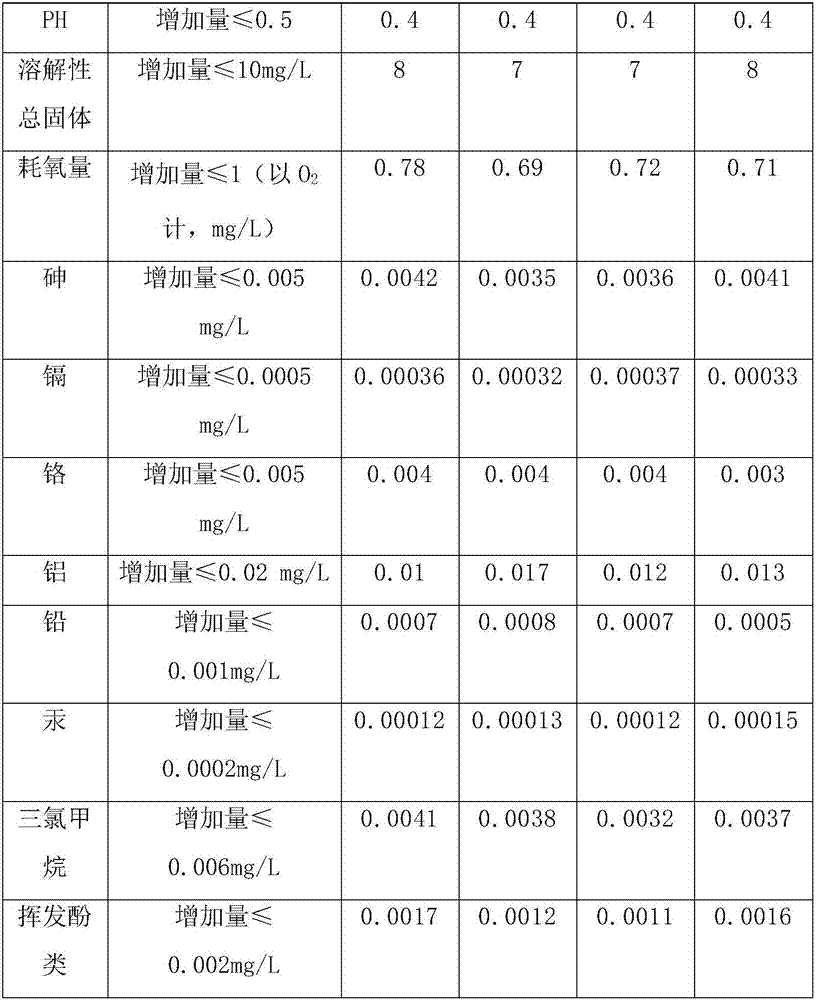

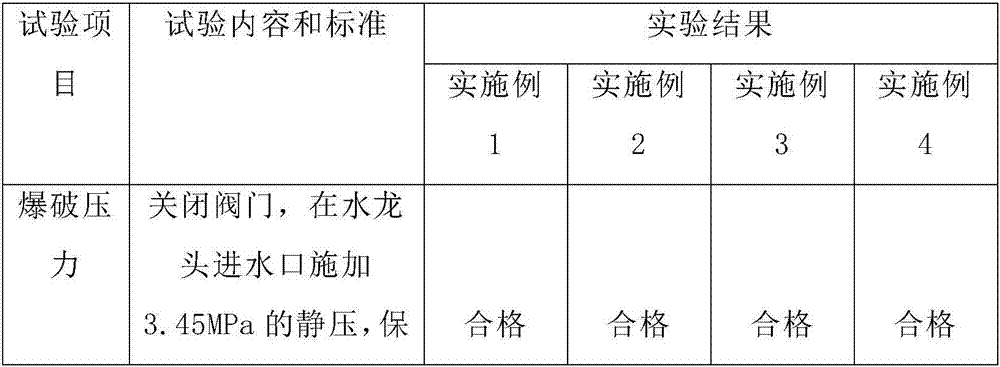

Examples

Embodiment 1

[0023] (1) Pottery clay configuration: mix 15 parts of raw talc, 65 parts of cooked talc, 15 parts of clay, and 8 parts of barium carbonate according to the parts by mass, calcinate at 1100°C for 2 hours, and then grind them with a ball mill. A 250-mesh sieve was used to obtain clay powder, and then the clay powder was mixed with 50 parts of paraffin, heated until the paraffin melted and then stirred evenly. The temperature during the stirring process was controlled at 65° C. to obtain the desired clay.

[0024] (2) Water channel forming: The ceramic clay is hot die-casted into a water channel blank, and the water channel blank is calcined and dewaxed. The calcination temperature is 1350°C, and the calcination time is 3 hours. After calcination, it is naturally cooled to room temperature, and then the surface is polished. Water immersion maintenance is then carried out, and the maintenance time is 1 day. After the maintenance is completed, the required ceramic water channel is ...

Embodiment 2

[0028] (1) Ceramic clay configuration: mix 20 parts of raw talc, 75 parts of cooked talc, 25 parts of clay, and 10 parts of barium carbonate according to the parts by mass, calcinate at 1150°C for 3 hours, and then grind them with a ball mill. A 300-mesh sieve was used to obtain clay powder, and then the clay powder was mixed with 60 parts of paraffin, heated until the paraffin melted and then stirred evenly. The temperature during the stirring process was controlled at 70° C. to obtain the desired clay.

[0029] (2) Forming of water channel: hot die-casting of ceramic clay to make water channel blank, dewaxing the water channel blank, calcination temperature is 1380°C, calcination time is 4h, after calcination, it is naturally cooled to room temperature, and then the surface is polished. Water immersion maintenance is then carried out, and the maintenance time is 2 days. After the maintenance is completed, the required ceramic water channel is obtained.

[0030] (3) Preparati...

Embodiment 3

[0033] (1) Ceramic clay configuration: Mix 17 parts of raw talc, 70 parts of cooked talc, 20 parts of clay, and 9 parts of barium carbonate according to the parts by mass, calcinate at 1130°C for 2.5 hours, and then grind with a ball mill. Pass through a 250-mesh sieve to obtain clay powder, then mix the clay powder with 55 parts of paraffin, heat until the paraffin melts, and stir evenly. The temperature during the stirring process is controlled at 68° C. to obtain the desired clay.

[0034] (2) Water channel molding: The ceramic clay is hot die-casted into a water channel blank, and the water channel blank is calcined and dewaxed. The calcination temperature is 1370°C, and the calcination time is 3.5h. After calcination, it is naturally cooled to room temperature, and then the surface is polished. , and then carry out immersion maintenance, the maintenance time is 1.5d, and the required ceramic water channel will be obtained after the maintenance is completed.

[0035] (3) P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com