Composite fabric based on graphene composite fibers and production method thereof

A graphene composite and composite fabric technology, which is applied in the field of textile technology composite materials, can solve the problems of not being able to meet the functional requirements of end products, the application effect is not very ideal, and does not have functionality, etc., and achieve good moisture absorption and breathability. Mass production, soft touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

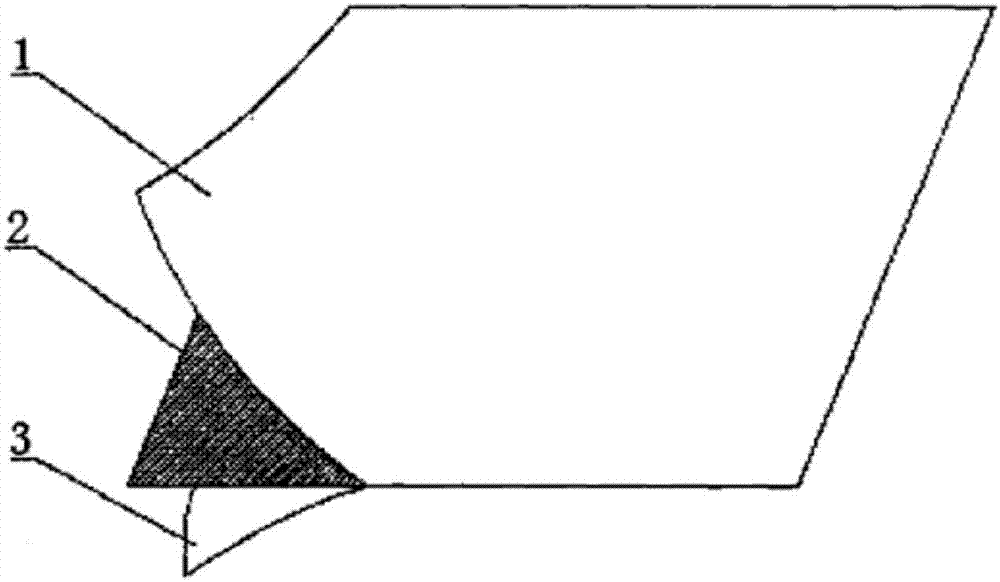

Method used

Image

Examples

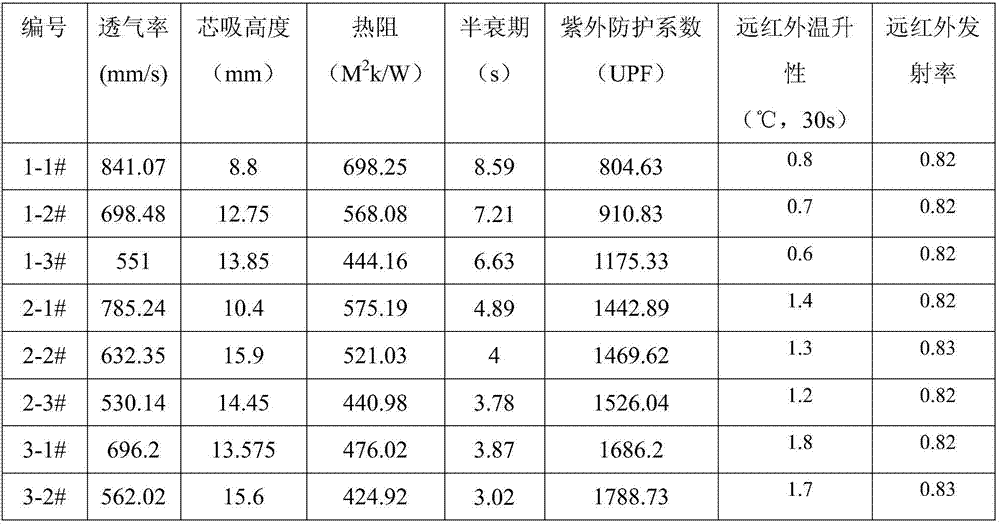

Embodiment 1

[0041] The base fabric of the functional layer is 100% phase change fiber spunlace nonwoven material, and does not contain graphene composite fiber. This group is mainly used as a comparison sample. The specific operation steps are as follows

[0042] a. Phase change fiber according to 60g / m 2 , 80g / m 2 , 100g / m 2 The square meter weight is weighed at a ratio of 0 / 100, specifically weighing 11.7g, 15.6g, and 19.5g;

[0043] b. The weighed fibers are mixed, loosened, evenly carded and laid in parallel on the carding machine, wherein the number of carding channels is 3;

[0044] c. Send the laid web to the Fieissner Aquajet spunlace machine for spunlace, using 5 spunlace heads, the first one is pre-wet spunlace, the remaining 4 are front and back spunlace, and finally dried , where the specification of the jet plate is 0.6 mm in hole distance and 0.12 mm in hole diameter, and the shape of the water spray hole is conical shrinkage;

[0045] d. Lay the 3D upright cotton flat a...

Embodiment 2

[0049] The functional layer base fabric is 20% / 80% graphene composite fiber / phase change fiber spunlace nonwoven material, and the specific operation steps are as follows:

[0050] a. The graphene composite fiber and phase change fiber are 60g / m 2 , 80g / m 2 , 100g / m 2 The square meter weight is weighed at 20% / 80% ratio, specifically weighing 2.36g / 9.36g, 3.12g / 12.48g, 3.9g / 156g;

[0051] b. The weighed fibers are mixed, loosened, evenly carded and laid in parallel on the carding machine, wherein the number of carding channels is 3;

[0052] c. Send the laid web to the Fieissner Aquajet spunlace machine for spunlace, using 5 spunlace heads, the first one is pre-wet spunlace, the remaining 4 are front and back spunlace, and finally dried . Among them, the specifications of the water jet plate are 0.6mm hole distance and 0.12mm hole diameter, and the shape of the water spray hole is conical contraction type;

[0053] d. Lay the 3D upright cotton flat and fix it on the glass ...

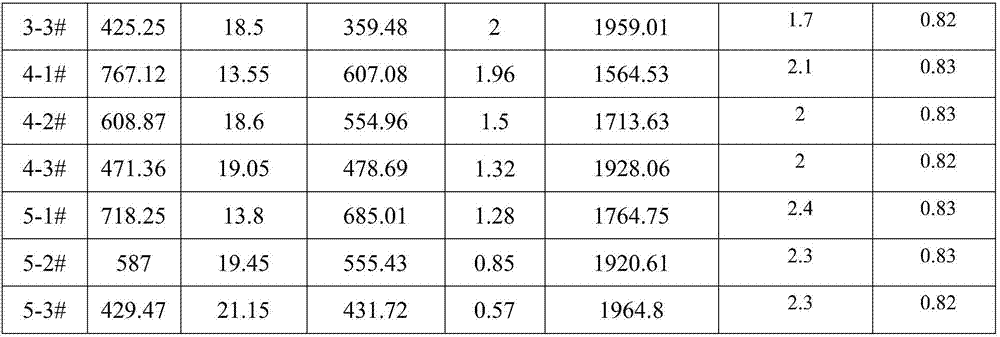

Embodiment 3

[0057] The functional layer base fabric is 50% / 50% graphene composite fiber / phase change fiber spunlace nonwoven material, and the specific operation steps are as follows:

[0058] a. The graphene composite fiber phase change fiber according to 60g / m 2 , 80g / m 2 , 100g / m 2 The square meter weight is weighed at a ratio of 50% / 50%, specifically weighing 5.85g / 5.85g, 7.8g / 7.8g, and 9.75g / 9.75g;

[0059] b. The weighed fibers are mixed, loosened, evenly carded and laid in parallel on the carding machine, wherein the number of carding channels is 3;

[0060] c. Send the laid web to the Fieissner Aquajet spunlace machine for spunlace, using 5 spunlace heads, the first one is pre-wet spunlace, the remaining 4 are front and back spunlace, and finally dried , where the specification of the jet plate is 0.6 mm in hole distance and 0.12 mm in hole diameter, and the shape of the water spray hole is conical shrinkage;

[0061] d. Lay the 3D upright cotton flat and fix it on the glass p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com