Room temperature self-crosslinking water-based epoxy ester and preparation method thereof

A self-crosslinking, epoxy ester technology, used in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of poor corrosion resistance, poor water resistance, poor weather resistance, etc., to improve corrosion resistance and excellent corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0024] A room temperature self-crosslinking water-based epoxy ester, including linoleic acid, epoxy resin E-20, epoxy resin E-03, benzoic acid, phthalic anhydride, antioxidant, polyaziridine crosslinking agent and ethylene glycol Alcohol butyl ether; In parts by mass, the linoleic acid: 29 parts; Epoxy resin E-20: 14 parts; Epoxy resin E-03: 10 parts; Benzoic acid: 6 parts; Phthalic anhydride: 3 parts; Antioxidant: 0.2 parts; polyaziridine crosslinking agent: 1 part; ethylene glycol butyl ether 21.5 parts.

[0025] Wherein, the epoxy resin E-20 is bisphenol A epoxy resin (E-20).

[0026] The epoxy resin E-03 is bisphenol A type epoxy resin (E-03).

[0027] The polyaziridine crosslinking agent is a trifunctional aziridine crosslinking agent.

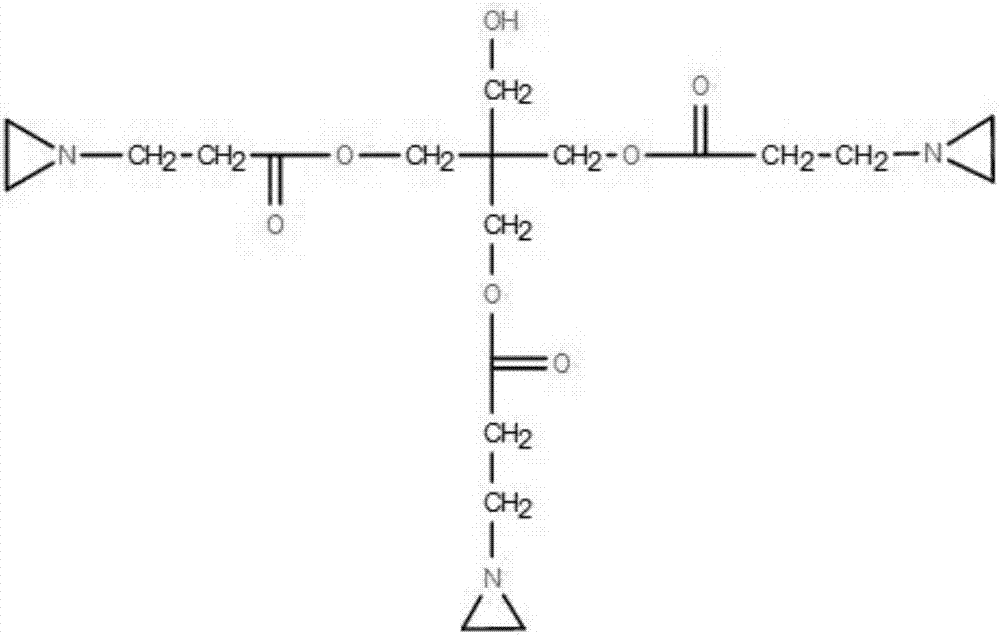

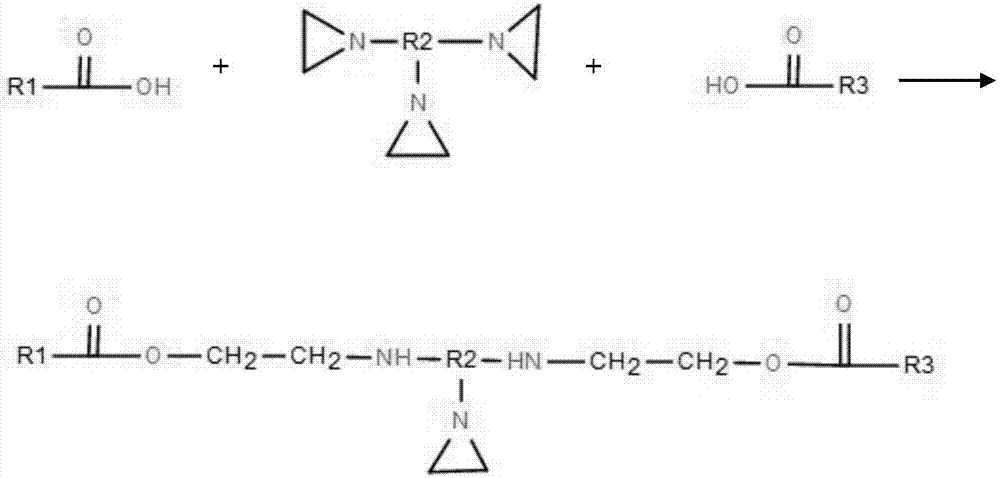

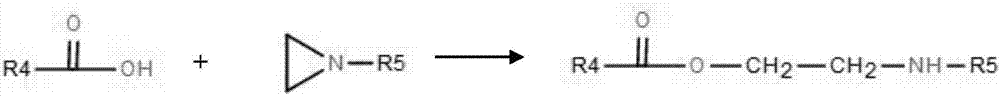

[0028] Further, the trifunctional aziridine crosslinking agent is trimethylolpropane-tris[3-(2-methylaziridinyl)]propionate, trimethylolpropane-tri(3- aziridinyl) propionate or pentaerythritol-tris(3-aziridinyl) propionate).

[0029] ...

Embodiment approach 2

[0056] A room temperature self-crosslinking water-based epoxy ester, in parts by mass, the linoleic acid: 32 parts; epoxy resin E-20: 16 parts; epoxy resin E-03: 12.5 parts; benzoic acid: 7.5 parts; Phthalic anhydride: 3.8 parts; Antioxidant: 0.2 parts; Polyaziridine crosslinking agent: 2 parts; 25 parts of ethylene glycol butyl ether. After adopting the above proportioning, the heat preservation time of step 4 of the preparation method is set to 4 hours. After the product is prepared, the product effect is tested to meet the requirements, and it is applied to the water-based industrial anti-corrosion coating. The prepared water-based industrial coating has good water resistance, corrosion resistance and adhesion to the substrate.

Embodiment approach 3

[0058] A room temperature self-crosslinking type water-based epoxy ester, in parts by mass, the linoleic acid: 26 parts; epoxy resin E-20: 12 parts; epoxy resin E-03: 8.5 parts; benzoic acid: 4.8 parts; Phthalic anhydride: 2.2 parts; Antioxidant: 0.2 parts; Polyaziridine crosslinking agent: 0.5 parts; 18 parts of ethylene glycol butyl ether. After adopting the above proportioning, the heat preservation time of step 4 of the preparation method is set to 3 hours. After the product is prepared, the product effect is tested to meet the requirements, and it is applied to the water-based industrial anti-corrosion coating. The prepared water-based industrial coating has good water resistance, corrosion resistance and adhesion to the substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com