Non-sulfur modified heat-resistant neoprene rubber

A chloroprene rubber and non-sulfur technology is applied in the field of non-sulfur regulated heat-resistant chloroprene rubber, which can solve the problems of human body pollution, pharmaceutical exudates, volatiles, difficulty in preparing rubber products, etc., and achieves low cost, simple method, Good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

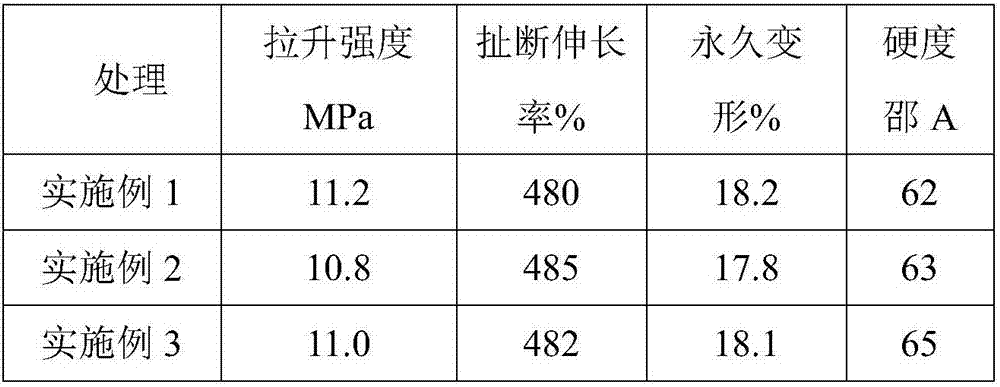

Embodiment 1

[0014] A non-sulfur-regulated chloroprene rubber heat-resistant formula, the formula ingredients are as follows: 90 parts by weight of non-sulfur-regulated chloroprene rubber, 3 parts by weight of antioxidant Oetamine, 2 parts by weight of anti-aging agent Aranox, 5 parts by weight of magnesium oxide, dodecyl carbon 2 parts by weight of mercaptan, 2 parts by weight of stearic acid, 110 parts by weight of light calcium carbonate, 20 parts by weight of rapeseed oil, 12 parts by weight of zinc oxide, and 1.5 parts by weight of accelerator NA-22.

Embodiment 2

[0016] A non-sulfur-regulated chloroprene rubber heat-resistant formula, the formula ingredients are as follows: 120 parts by weight of non-sulfur-regulated chloroprene rubber, 5 parts by weight of antioxidant Oetamine, 0.5 parts by weight of anti-aging agent Aranox, 3 parts by weight of magnesium oxide, ten parts by weight 2 parts by weight of dicarbon mercaptan, 1 part by weight of stearic acid, 110 parts by weight of light calcium carbonate, 13 parts by weight of rapeseed oil, 8 parts by weight of zinc oxide, and 0.5 part by weight of accelerator NA-22.

Embodiment 3

[0018] A non-sulfur-regulated chloroprene rubber heat-resistant formula, the formula ingredients are as follows: 100 parts by weight of non-sulfur-regulated chloroprene rubber, 4 parts by weight of anti-aging agent Oetamine, 1 part by weight of anti-aging agent Aranox, 3 parts by weight of magnesium oxide, dodecyl carbon 3 parts by weight of mercaptan, 1.5 parts by weight of stearic acid, 105 parts by weight of light calcium carbonate, 15 parts by weight of rapeseed oil, 10 parts by weight of zinc oxide, and 1 part by weight of accelerator NA-22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com