A combined control method of acid-resistant chelating resin for recovery of complex heavy metals by mass separation

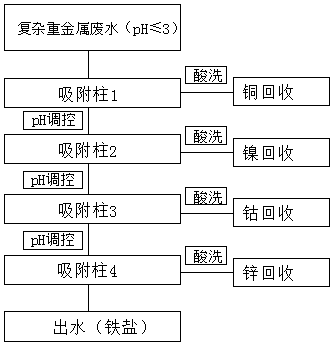

A technology for chelating resins and heavy metals, applied in chemical instruments and methods, improvement of process efficiency, water/sludge/sewage treatment, etc., can solve the problems of inability to selectively separate and recycle heavy metals in multiple stages, and achieve reduction Treatment costs and environmental risks, efficient concentration and purification recovery, the effect of achieving zero discharge and resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

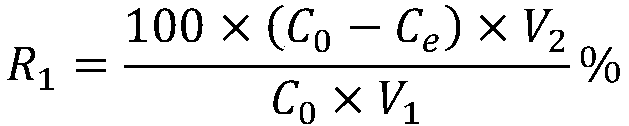

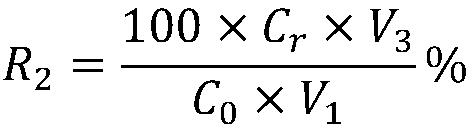

[0043] First, the wastewater containing copper, nickel and iron (both 50mg / L) with an initial pH value of 0.5 is pumped into the adsorption column filled with 5mL resin A The adsorption temperature is controlled at 20°C, the adsorption flow rate is 8BV / h, the effluent is collected and the pH value is adjusted to 1.2, and then pumped into the adsorption column filled with 5mL resin A The adsorption temperature was controlled at 20°C, the adsorption flow rate was 4BV / h, and the effluent was collected again. The chelating resin after selective adsorption of copper and nickel was desorbed and regenerated with 20% sulfuric acid and 10% hydrochloric acid respectively. The regeneration temperature was 20°C and the flow rate was 4BV / h. The desorbed and regenerated chelating resin is washed with water to neutrality and can be reused.

Embodiment 2

[0045] First, the wastewater containing copper, cobalt and iron (both 50mg / L) with an initial pH value of 0.8 is pumped into the adsorption column filled with 5mL resin A The adsorption temperature is controlled at 30°C, the adsorption flow rate is 6BV / h, the effluent is collected and the pH value is adjusted to 1.9, and then pumped into the adsorption column filled with 5mL resin B The adsorption temperature was controlled at 30°C, the adsorption flow rate was 5BV / h, and the effluent was collected again. The chelating resin after selective adsorption of copper and cobalt was desorbed and regenerated with 20% nitric acid and 10% hydrochloric acid respectively. The regeneration temperature was 40°C and the flow rate was 10BV / h. The desorbed and regenerated chelating resin is washed with water to neutrality and can be reused.

Embodiment 3

[0047] First, the wastewater containing copper, zinc and iron (both 50 mg / L) with an initial pH value of 1.1 is pumped into an adsorption column filled with 5 mL of resin A The adsorption temperature is controlled at 25°C, the adsorption flow rate is 3BV / h, the effluent is collected and the pH value is adjusted to 2.4, and then pumped into the adsorption column filled with 5mL resin B The adsorption temperature was controlled at 25°C, the adsorption flow rate was 3BV / h, and the effluent was collected again. The chelating resin after selective adsorption of copper and zinc was desorbed and regenerated with 10% sulfuric acid and 5% hydrochloric acid respectively. The regeneration temperature was 15°C and the flow rate was 1BV / h. The desorbed and regenerated chelating resin is washed with water to neutrality and can be reused.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption temperature | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com