A method for resource recovery of high acid and high iron heavy metal wastewater

A technology for resource recovery and heavy metal, applied in the fields of metallurgical wastewater treatment, mining wastewater treatment, chemical instruments and methods, etc., can solve the problems of poor selectivity, large consumption of chemicals, low removal rate of heavy metal ions, etc. The effect of efficient concentration recovery, reduction of chemical consumption and sludge production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

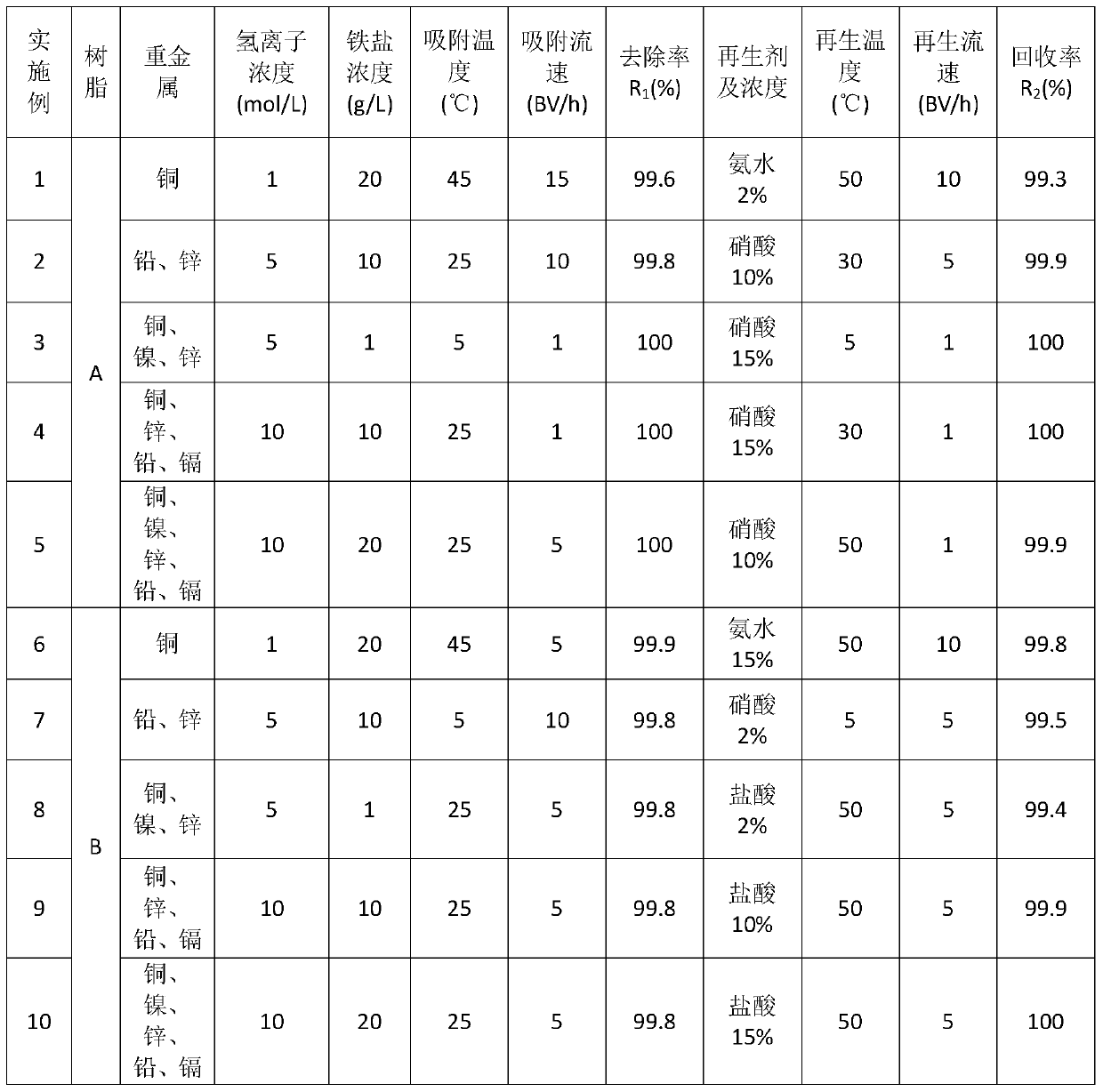

Examples

Embodiment 1

[0027] A method for resource recovery of high-acid and high-iron heavy metal wastewater, the steps of which are:

[0028] (1) At first, the copper-containing (100mg / L) wastewater containing 20g / L ferric nitrate and a hydrogen ion concentration of 1mol / L is pumped into an adsorption column filled with 200mL strong base anion exchange resin (201×7 type), until When the effluent pH2 stop regeneration.

[0029] (2) then the above-mentioned high-iron heavy metal ion wastewater is passed through the acrylic aminopyridine chelating resin disclosed in 2015102049229 (resin in embodiment 4) that is equipped with 4mL resin A (Chinese patent application number is 2015102049229) C)) glass adsorption column ( 10×240mm), the adsorption temperature is controlled at 45°C, and the effluent is collected (the effluent after being adsorbed by resin A is low-concentration inorganic acid and high-concentration iron salt wastewater). When the concentration of heavy metals in the effluent reaches ...

Embodiment 2

[0036] A method for resource recovery of high-acid and high-iron heavy metal wastewater, the steps of which are:

[0037] (1) First, pump waste water containing 10g / L ferric sulfate and a hydrogen ion concentration of 5mol / L containing lead and zinc (both at a concentration of 50mg / L) into a 200mL strong base anion exchange resin (201×7 type) When the pH of the effluent is less than 1, stop pumping waste water and press out the resin void solution with an air compressor. The effluent after being adsorbed by anion exchange resin is high-iron heavy metal ion waste water, and then regenerate with clean water countercurrently to collect the regenerated solution. Stop regeneration when the regeneration water pH>2.

[0038] (2) then the above-mentioned high-iron heavy metal ion wastewater is passed through the acrylic aminopyridine chelating resin disclosed in 2015102049229 (resin in embodiment 4) that is equipped with 4mL resin A (Chinese patent application number is 2015102049229)...

Embodiment 3

[0041] A method for resource recovery of high-acid and high-iron heavy metal wastewater, the steps of which are:

[0042] (1) First, pump waste water containing 1g / L ferric chloride and a hydrogen ion concentration of 5mol / L containing copper, nickel, and zinc (both at a concentration of 150mg / L) into a 200mL strong base anion exchange resin (201× Type 4) adsorption column, stop pumping waste water when the effluent pH2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com