Salt-free dyeing method with short liquor dyeing and ultra light color using active dye

A reactive dye and salt-free dyeing technology, applied in the field of salt-free dyeing, can solve the problems of no popularization and application, difficult operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

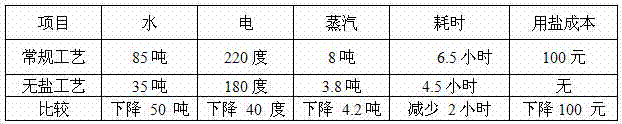

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The gray fabric is 140 grams of cotton jersey (children's clothing), the dyeing tank is a downstream air dyeing tank, the color is beige, and the reactive dye is Kyung In Co., Ltd. of Korea.

[0024] The process steps are:

[0025] 1) Gray fabric pre-treatment, the materials are configured according to the following mass percentages: hydrogen peroxide 3.5%, oxygen bleaching stabilizer TF-122 (Transfar Zhilian Co., Ltd.) 0.4%, caustic soda 4%, degreasing agent DS-1130 (Shaoxing Keqiao Demei Chemical Co., Ltd.) 0.5%, high-efficiency scouring agent TF-125T (Transfar Zhilian Co., Ltd.) 1%, chelating agent 540A (Ningbo Guoguang Chemical Auxiliary Industry and Trade Co., Ltd.) 0.4%, glacial acetic acid 0.8%, over Catalase UTA656 (Hunan Youtel Biochemical Co., Ltd.) 0.1%; the specific process is: the bath ratio is 1:4, and the tank is run at 50°C for 5 minutes before adding oxygen bleaching stabilizer TF-122 and degreasing agent DS in sequence After -1130, high-efficiency sco...

Embodiment 2

[0043] The gray fabric is 310g terry cloth (children's clothes), the dyeing vat is a downstream dyeing vat, the color is lotus root pink, and the reactive dye is Kyungin Co., Ltd. of Korea.

[0044] The process steps are:

[0045] 1) Gray fabric pre-treatment, the materials are configured according to the following mass percentages: hydrogen peroxide 3.5%, oxygen bleaching stabilizer TF-122 (Transfar Zhilian Co., Ltd.) 0.4%, caustic soda 4%, degreasing agent DS-1130 (Shaoxing Keqiao Demei Chemical Co., Ltd.) 0.5%, high-efficiency scouring agent TF-125T (Transfar Zhilian Co., Ltd.) 1%, chelating agent 540A (Ningbo Guoguang Chemical Auxiliary Industry and Trade Co., Ltd.) 0.4%, glacial acetic acid 0.8%, over Catalase UTA656 (Hunan Youtel Biochemical Co., Ltd.) 0.1%; the specific process is: the bath ratio is 1:4, and the tank is run at 50°C for 5 minutes before adding oxygen bleaching stabilizer TF-122 and degreasing agent DS in sequence After -1130, high-efficiency scouring agen...

Embodiment 3

[0063] The gray fabric is 160 grams of cotton spandex single jersey (underwear), the dyeing tank is a downstream dyeing tank, the color is light pink, and the reactive dye is Kyung In & Co., Korea.

[0064] Process steps:

[0065] 1) The gray fabric is pre-treated after pre-setting, and the materials are configured according to the following mass percentages: hydrogen peroxide 3.5%, oxygen bleaching stabilizer TF-122 (Transfar Zhilian Co., Ltd.) 0.4%, caustic soda 4%, degreasing agent DS-1130 (Shaoxing Keqiao Demei Chemical Co., Ltd.) 0.5%, high-efficiency scouring agent TF-125T (Transfar Zhilian Co., Ltd.) 1%, chelating agent 540A (Ningbo Guoguang Chemical Auxiliary Industry and Trade Co., Ltd.) 0.4%, glacial acetic acid 0.8%, catalase UTA656 (Hunan Youtel Biochemical Co., Ltd.) 0.1%; the specific process is: the bath ratio is 1:4, and the tank is run at 50°C for 5 minutes before adding the oxygen bleaching stabilizer TF-122, After degreasing agent DS-1130, high-efficiency s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com