Preparation method and application of polyelectrolyte compound with stress response and patterned micro-nano structure

A technology of micro-nano structure and polyelectrolyte, which is applied in the field of preparation of polyelectrolyte composites, can solve the problems of high price of humidity sensors, non-availability, and the inability of industrialized production of composite sensors to achieve the effect of accurate, fast and low-cost detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

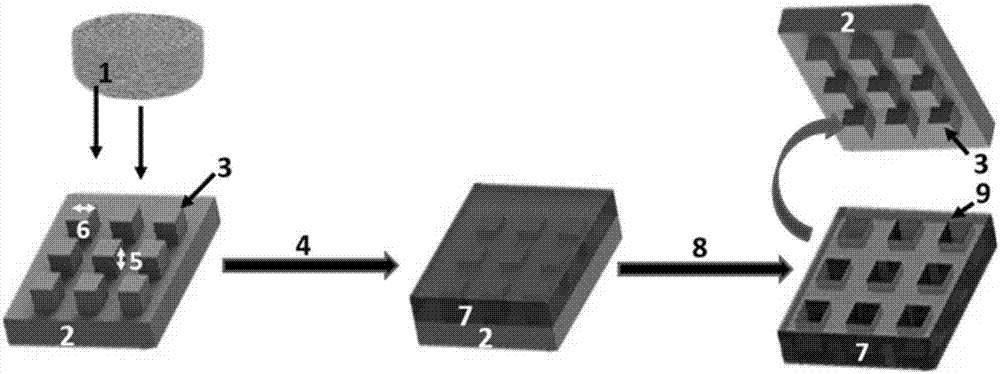

[0048] Specific Embodiment 1: This embodiment is a method for preparing a polyelectrolyte complex with a patterned micro-nano structure that responds to stress, and it is specifically completed in the following steps:

[0049] 1. Preparation of patterned PDMS stamps:

[0050] Mix polydimethylsiloxane prepolymer A and curing agent B, first stir at a stirring speed of 200r / min to 500r / min for 5min to 8min, then stir at a centrifugal speed of 3000r / min to 4000r / min Centrifuge for 5min to 8min to obtain a mixed solution; pour the mixed solution into a petri dish equipped with a patterned silicon substrate, and then vacuum cure the petri dish at a temperature of 60°C to 80°C for 1h to 3h to obtain on the silicon substrate Patterned PDMS stamp; peeling the patterned PDMS stamp from the silicon substrate to obtain a patterned PDMS stamp;

[0051] The mass ratio of prepolymer A and curing agent B of the polydimethylsiloxane described in step 1 is 10:1;

[0052] Two, the preparation ...

specific Embodiment approach 2

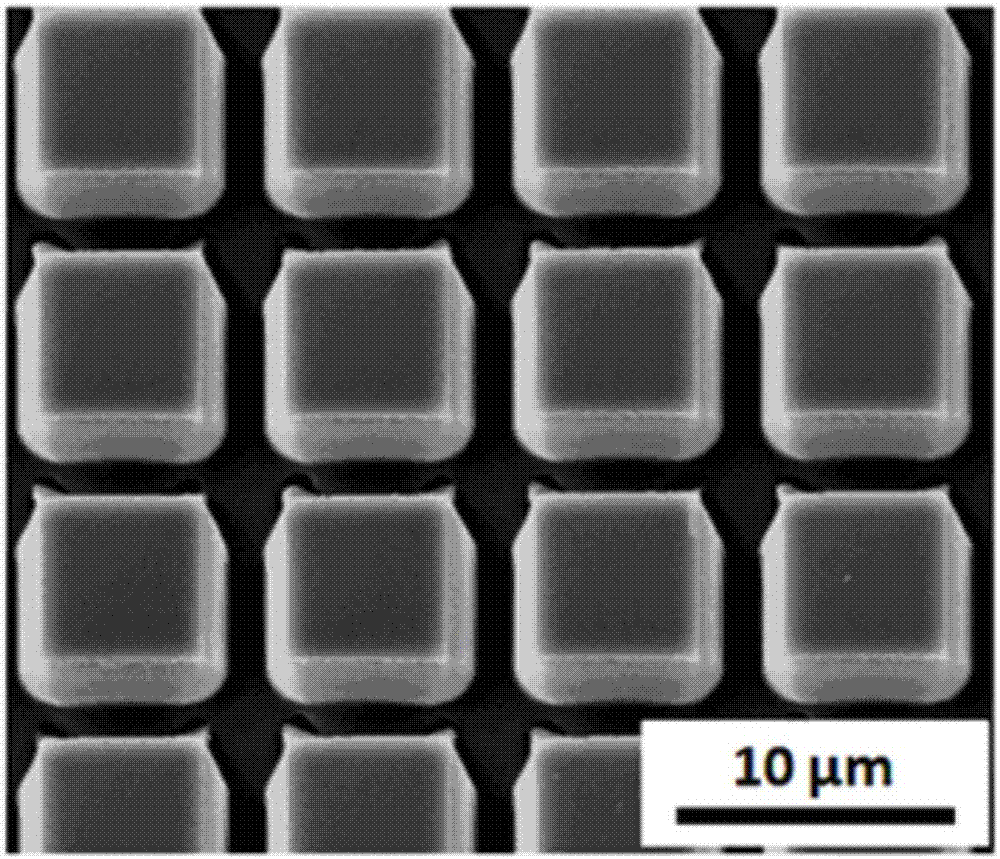

[0064] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the patterned PDMS stamp described in step 1 is a cube with a side length of 10 μm in the array. Others are the same as the first embodiment.

specific Embodiment approach 3

[0065] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the sodium chloride solution of polystyrene sodium sulfonate described in step 2 is polystyrene sodium sulfonate, sodium chloride and distilled water The mixed solution, the concentration of polystyrene sodium sulfonate in the sodium chloride solution of polystyrene sodium sulfonate is 2mg / mL, the concentration of sodium chloride is 2mol / L; the sodium chloride solution of the polyacrylate It is a mixed solution of polyacrylate, sodium chloride and distilled water, the concentration of polyacrylate in the sodium chloride solution of polyacrylate is 2mg / mL, and the concentration of sodium chloride is 2mol / L. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com