Method for measuring tungsten content in ferromolybdenum through inductively coupled plasma atomic emission spectrometry

An atomic emission spectrometry and plasma technology is applied in the field of plasma atomic emission spectrometry for the determination of tungsten content in ferromolybdenum, achieving the effect of simple operation, less interference factors and good measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

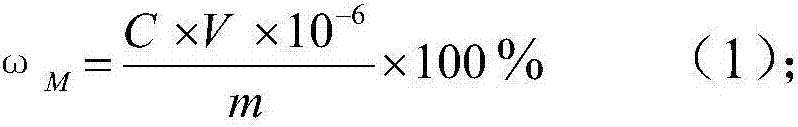

[0031] The method for measuring tungsten content in molybdenum iron by inductively coupled plasma atomic emission spectrometry, said method may further comprise the steps:

[0032] (1) Prepare the solution to be tested: weigh 0.200 g of the ferromolybdenum sample, place it in a 100ml steel dual-purpose bottle, add 5mL of nitric acid and 1mL of hydrochloric acid, heat at 300°C to 400°C until the ferromolybdenum sample dissolves, then cool slightly. Add 1mL of sulfuric acid and 1mL of phosphoric acid, heat until white smoke of sulfuric acid is emitted, continue to heat for 30S, cool slightly, add 2mL of hydrochloric acid, boil until the salt is completely dissolved, after cooling, dilute to 100mL with deionized water, and mix well Prepare the solution to be tested;

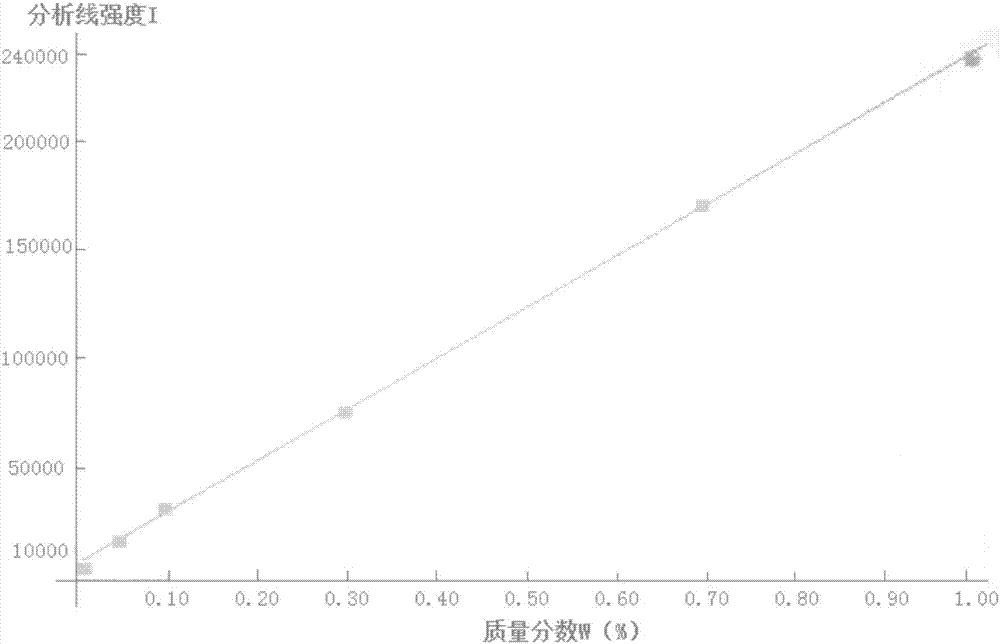

[0033] (2) Preparation of standard series solutions: Dissolve seven groups of 0.12g metal molybdenum and 0.07g high-purity iron with 5mL concentrated nitric acid respectively, transfer them into a 100mL single-scale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com