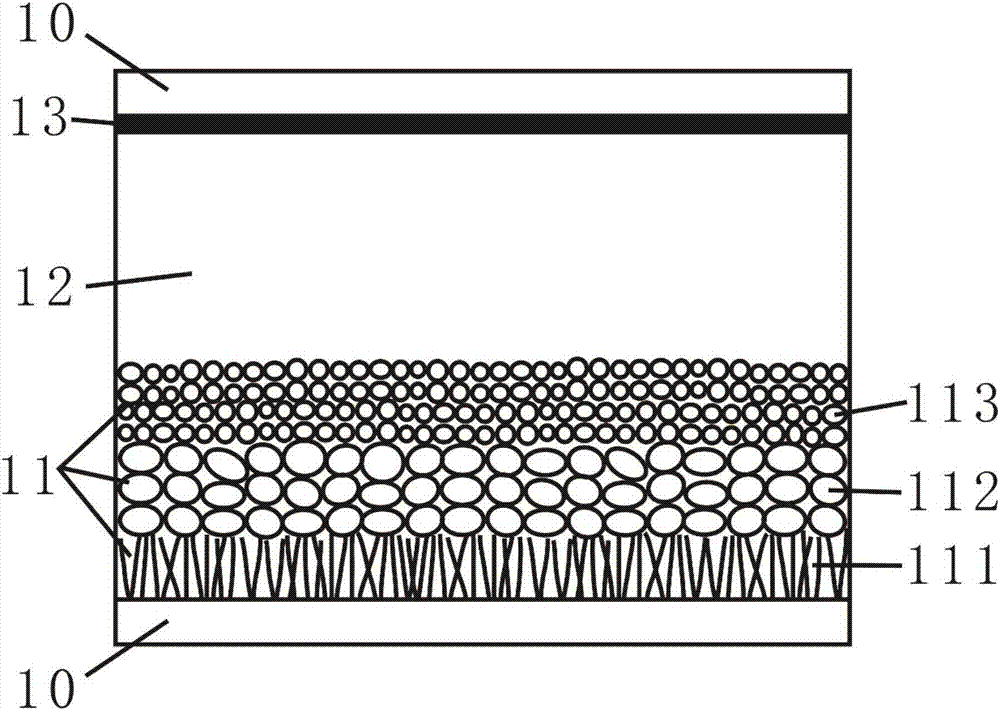

Solar cell based on composite nanostructured light anode

A composite nanostructure and solar cell technology, applied in the field of solar cells, can solve problems such as wasting sunlight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation process of the photoanode of the present application is:

[0035] Step 1, cleaning FTO conductive glass

[0036] First, put the FTO conductive glass cut to a suitable size into the diluted detergent solution for 20 minutes, pour off the detergent solution, rinse the glass surface with deionized water, and then put the FTO conductive glass into deionized water for ultrasonication 20min, then placed in acetone, ethanol, and deionized water in order to sonicate for 15min, blow dry with nitrogen, and set aside;

[0037] Step 2, preparation of ZnO seed layer

[0038] First, configure a solution containing 0.05mol zinc acetate, 0.06mol diethanolamine and 100ml absolute ethanol, stir magnetically for 30min at room temperature, then put it into an oil bath at 60°C for 10h magnetically to obtain a seed layer solution, and then The cleaned FTO conductive glass was slowly dipped into the seed layer solution, allowed to stand for 13 seconds, and then slowly pulled...

Embodiment 1

[0049] Step 1, cleaning FTO conductive glass

[0050] First, put the FTO conductive glass cut to a suitable size into the diluted detergent solution for 20 minutes, pour off the detergent solution, rinse the glass surface with deionized water, and then put the FTO conductive glass into deionized water for ultrasonication 20min, then placed in acetone, ethanol, and deionized water in order to sonicate for 15min, blow dry with nitrogen, and set aside;

[0051] Step 2, preparation of ZnO seed layer

[0052] First, configure a solution containing 0.05mol zinc acetate, 0.06mol diethanolamine and 100ml absolute ethanol, stir magnetically for 30min at room temperature, then put it into an oil bath at 60°C for 10h magnetically to obtain a seed layer solution, and then The cleaned FTO conductive glass was slowly dipped into the seed layer solution, allowed to stand for 13 seconds, and then slowly pulled out at a pulling rate of 0.1 cm / s. Place the pulled FTO conductive glass in an ov...

Embodiment 2

[0064] Step 1, cleaning FTO conductive glass

[0065] First, put the FTO conductive glass cut to a suitable size into the diluted detergent solution for 20 minutes, pour off the detergent solution, rinse the glass surface with deionized water, and then put the FTO conductive glass into deionized water for ultrasonication 20min, then placed in acetone, ethanol, and deionized water in order to sonicate for 15min, blow dry with nitrogen, and set aside;

[0066] Step 2, preparation of ZnO seed layer

[0067] First, configure a solution containing 0.05mol zinc acetate, 0.06mol diethanolamine and 100ml absolute ethanol, stir magnetically for 30min at room temperature, then put it into an oil bath at 60°C for 10h magnetically to obtain a seed layer solution, and then The cleaned FTO conductive glass was slowly dipped into the seed layer solution, allowed to stand for 13 seconds, and then slowly pulled out at a pulling rate of 0.1 cm / s. Place the pulled FTO conductive glass in an ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com