Green transmutation sagging ceramic product and manufacturing process thereof

A technology of ceramic products and production process, which is applied in the field of green kiln variable flow glaze ceramic products and its production process, which can solve the problems of great threat to staff accidents, shortened service life of utensils, and low production success rate, so as to speed up product production efficiency, The effect of reducing energy consumption and increasing the amount of quartz used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

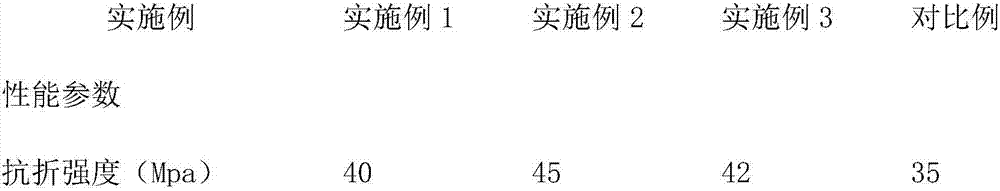

Examples

Embodiment 1

[0058] A green kiln variable flow glaze ceramic product, the raw materials for its preparation include the following materials in parts by weight:

[0059] 70 parts of nepheline;

[0060] 8 parts of dolomite;

[0061] 6 parts of kaolin;

[0062] Quartz 9 parts;

[0063] 5 parts of mica;

[0064] 1 part bentonite;

[0065] 13 parts of titanium dioxide;

[0066] 3 parts of zinc oxide;

[0067] Calcium oxide 12 parts;

[0068] 2 parts copper oxide;

[0069] 2 parts of waste Ti ceramic particles.

[0070] The manufacturing process of the above-mentioned green kiln variable flow glaze ceramic product comprises the following steps:

[0071] (1) Material processing: selecting materials according to parts by weight, ball milling nepheline, dolomite, kaolin, quartz, mica, bentonite and waste ceramic materials respectively;

[0072] (2) Material distribution: distribute the above-mentioned ground materials:

[0073] a. Green body weight ingredients: take 54 parts of nepheline...

Embodiment 2

[0082] A green kiln variable flow glaze ceramic product, the raw materials for its preparation include the following materials in parts by weight:

[0083] 85 parts of nepheline;

[0084] 12 parts of dolomite;

[0085] 10 parts of kaolin;

[0086] Quartz 13 parts;

[0087] 10 parts of mica;

[0088] 5 parts of bentonite;

[0089] 16 parts of titanium dioxide;

[0090] 7 parts of zinc oxide;

[0091] Calcium oxide 18 parts;

[0092] 6 parts of copper oxide;

[0093] 5 parts of waste Ti ceramic particles.

[0094] The manufacturing process of the above-mentioned green kiln variable flow glaze ceramic product comprises the following steps:

[0095] (1) Material processing: selecting materials according to parts by weight, ball milling nepheline, dolomite, kaolin, quartz, mica, bentonite and waste ceramic materials respectively;

[0096] (2) Material distribution: distribute the above-mentioned ground materials:

[0097] a. Green body weight ingredients: 65 parts of nep...

Embodiment 3

[0106] A green kiln variable flow glaze ceramic product, the raw materials for its preparation include the following materials in parts by weight:

[0107] 80 parts of nepheline;

[0108] 10 parts of dolomite;

[0109] 8 parts of kaolin;

[0110] Quartz 11 parts;

[0111] 8 parts of mica;

[0112] 5 parts of bentonite;

[0113] 15 parts of titanium dioxide;

[0114] 5 parts of zinc oxide;

[0115] Calcium oxide 15 parts;

[0116] 4 parts copper oxide;

[0117] 3 parts of waste Ti ceramic particles.

[0118] The manufacturing process of the above-mentioned green kiln variable flow glaze ceramic product comprises the following steps:

[0119] (1) Material processing: selecting materials according to parts by weight, ball milling nepheline, dolomite, kaolin, quartz, mica, bentonite and waste ceramic materials respectively;

[0120] (2) Material distribution: distribute the above-mentioned ground materials:

[0121] a. Body weight ingredients: take 62 parts of nepheline...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com