Method for preparing instant starch film

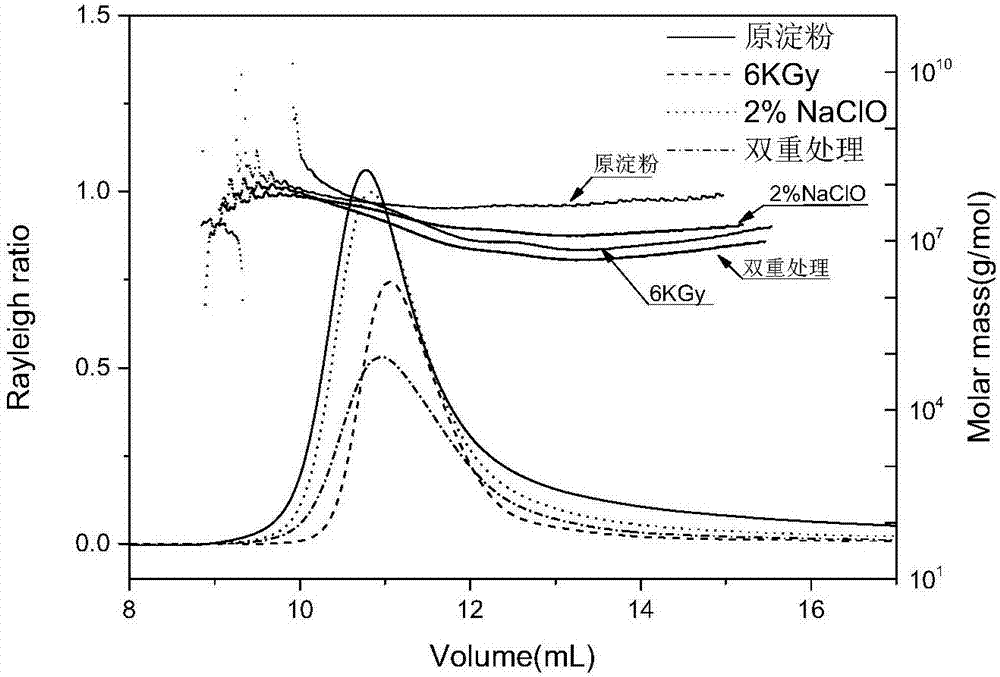

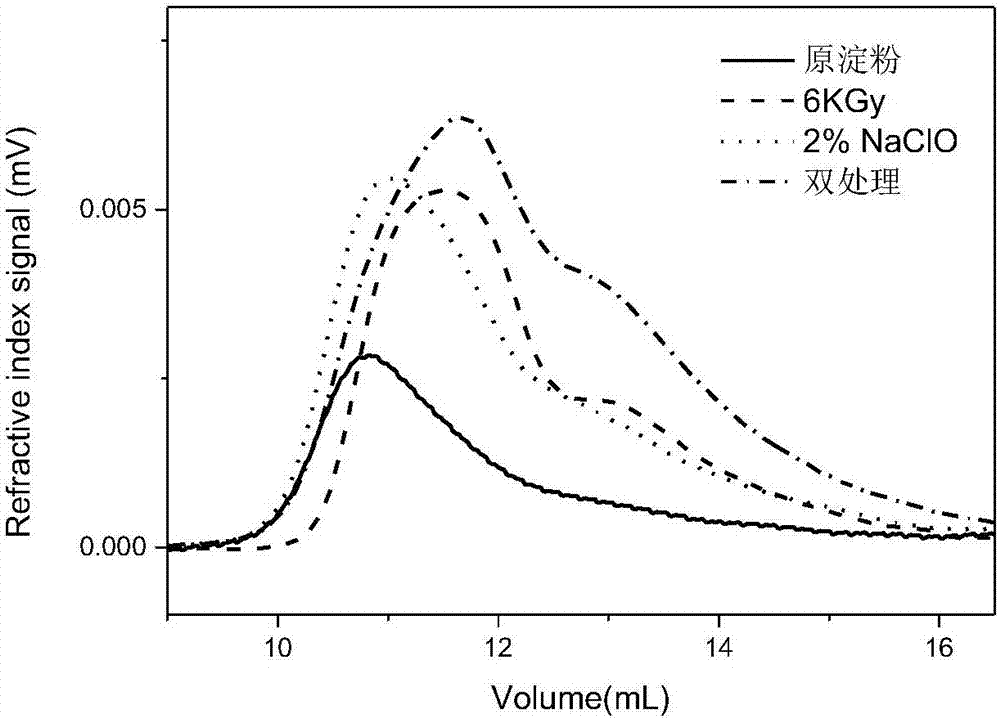

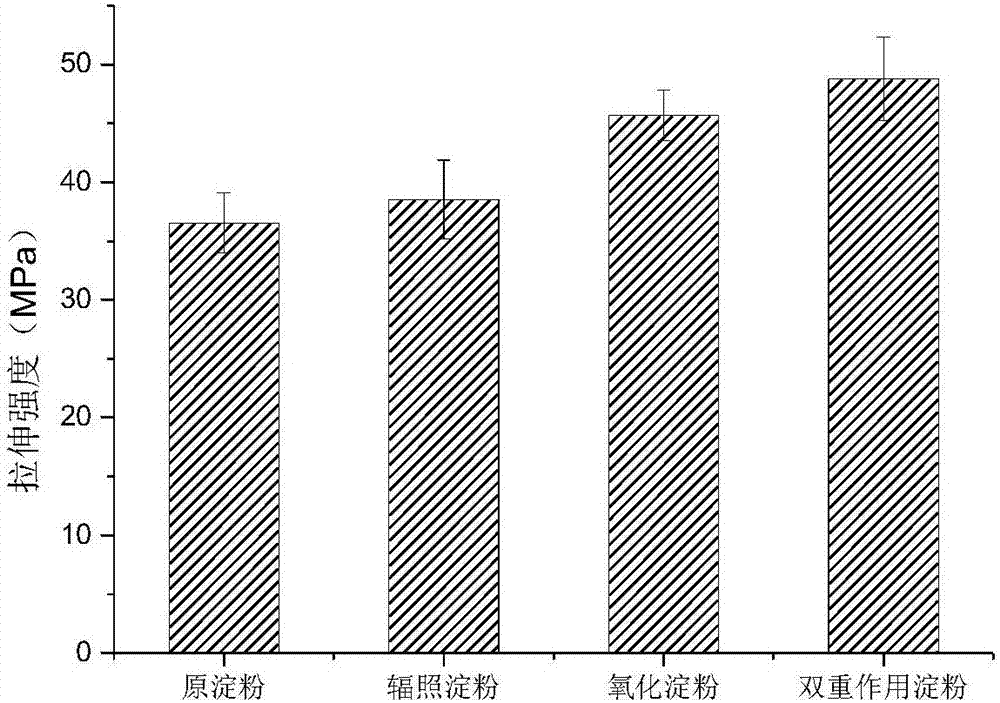

A starch film and instant technology, applied in the field of food packaging film, can solve the problems of insufficient mechanical properties of starch film, rare starch edible film, and no edible film process, achieving less possibility of shrinkage and bursting, and making up for starch Increased yellowness and good transparency of paste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of preparation method of instant starch film, described preparation method comprises the steps:

[0031] (1) Carrying out electron beam irradiation treatment to waxy cornstarch;

[0032] Put the waxy cornstarch in a ziplock bag and seal it, spread it flat, with a thickness of 1cm, then put the ziplock bag on the conveyor belt of the electron beam irradiation production line with an irradiation dose of 6kGy, and each rotation is one irradiation. The electron beam is produced by a 5Mev industrial electron accelerator with a dose rate of 2KGy / s.

[0033] (2) 20g of waxy cornstarch processed through step (1) is mixed with water to make a starch emulsion with a concentration of 40%. Afterwards, the starch emulsion is placed in a 45°C constant temperature water bath, stirred at a speed of 300rpm for 30min, and then Add sodium hypochlorite solution (available chlorine content accounts for 2% of starch dry base), constantly detect the pH of the reaction solution during ...

Embodiment 2

[0037] A kind of preparation method of instant starch film, described preparation method comprises the steps:

[0038] (1) potato starch is carried out electron beam irradiation treatment;

[0039] Put the potato starch in a ziplock bag and seal it, spread it flat, with a thickness of 0.8cm, and then put the ziplock bag on the conveyor belt of the electron beam irradiation production line with an irradiation dose of 10kGy, and each rotation is one irradiation, electron The beam is produced by a 5 Mev industrial electron accelerator with a dose rate of 2KGy / s.

[0040] (2) Mix 20 g of potato starch processed in step (1) with water to make a starch emulsion with a concentration of 20%, then place the starch emulsion in a constant temperature water bath at 40°C, stir for 20 minutes at a speed of 500 rpm, and then add sodium hypochlorite solution (available chlorine content accounts for 2% of the starch dry base), constantly detect the pH of the reaction solution in the reaction ...

Embodiment 3

[0044] A kind of preparation method of instant starch film, described preparation method comprises the steps:

[0045] (1) Carrying out electron beam irradiation treatment to cornstarch;

[0046] Put the cornstarch in a ziplock bag and seal it, spread it flat, with a thickness of 0.5cm, and then place the ziplock bag on the conveyor belt of the electron beam irradiation production line with an irradiation dose of 2kGy. The beam is produced by a 5 Mev industrial electron accelerator with a dose rate of 2KGy / s.

[0047] (2) Mix 20 g of cornstarch treated in step (1) with water to make a starch emulsion with a concentration of 30%, then place the starch emulsion in a constant temperature water bath at 30°C, stir for 30 minutes at a speed of 400 rpm, and then add sodium hypochlorite solution (available chlorine content accounts for 2% of starch dry base), constantly detect the pH of the reaction solution in the reaction process, adjust the pH value of the reaction solution to 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com