Antibacterial gel and preparation method thereof

A gel and gellan gum technology, which can be applied in pharmaceutical formulations, cosmetic preparations, toiletry preparations, etc., can solve the problems of no public reports of gellan gum grafted nisin, and improve the utilization rate of carboxyl groups , enhanced stability, and easy-to-gel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

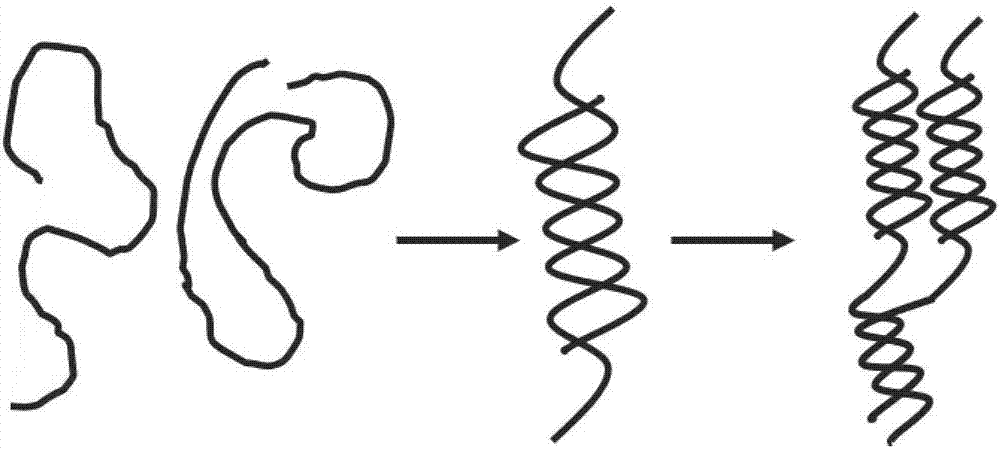

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: Preparation of antibacterial cleansing gel

[0040] (1) Weighing: 100 parts of low acyl gellan gum, 500 parts of nisin, 1000 parts of 2-(N-morpholine) ethanesulfonic acid, 1-(3-dimethylaminopropyl)-3-ethyl 30 parts of carbodiimide hydrochloride, 30 parts of N-hydroxysulfosuccinimide, and 100 parts by weight of deionized water are ready for use.

[0041] (2) Gellan gum pretreatment:

[0042] Deacyl: Gellan gum needs to be treated with hot alkali. The treatment method is to dissolve gellan gum solid powder with 0.05M sodium hydroxide solution, prepare a solution with a final concentration of 1% (w / v), boil it for 10 minutes, and the solution is golden yellow. Cool to room temperature and dialyze with deionized water until the dialysate is neutral and the yellow color fades to colorless, clear and transparent.

[0043] Deionization: Add the cation exchange resin to the low acyl gellan gum solution at a concentration of 30% (w / v), stir for 30 minutes, and tr...

Embodiment 2

[0050] Embodiment 2: the preparation of antibacterial cleansing gel

[0051] (1) Weighing: 90 parts of low acyl gellan gum, 450 parts of nisin, 1100 parts of 2-(N-morpholine) ethanesulfonic acid, 1-(3-dimethylaminopropyl)-3-ethyl 20 parts of carbodiimide hydrochloride, 20 parts of N-hydroxysulfosuccinimide, and 90 parts by weight of deionized water are ready for use.

[0052] (2) Gellan gum pretreatment:

[0053] Deacyl: Gellan gum needs to be treated with hot alkali. The treatment method is to dissolve gellan gum solid powder with 0.05M sodium hydroxide solution, prepare a solution with a final concentration of 1% (w / v), boil it for 10 minutes, and the solution is golden yellow. Cool to room temperature and dialyze with deionized water until the dialysate is neutral and the yellow color fades to colorless, clear and transparent.

[0054] Deionization: Add the cation exchange resin to the low acyl gellan gum solution at a concentration of 10% (w / v), stir for 10 min, and trea...

Embodiment 3

[0061] Embodiment 3: the preparation of antibacterial cleansing gel

[0062] (1) Weighing: 110 parts of low acyl gellan gum, 450 parts of nisin, 900 parts of 2-(N-morpholine) ethanesulfonic acid, 1-(3-dimethylaminopropyl)-3-ethyl 40 parts of carbodiimide hydrochloride, 40 parts of N-hydroxysulfosuccinimide, and 110 parts by weight of deionized water are ready for use.

[0063] (2) Gellan gum pretreatment:

[0064] Deacyl: Gellan gum needs to be treated with hot alkali. The treatment method is to dissolve gellan gum solid powder with 0.05M sodium hydroxide solution, prepare a solution with a final concentration of 2% (w / v), boil it for 20 minutes, and the solution is golden yellow. Cool to room temperature and dialyze with deionized water until the dialysate is neutral and the yellow color fades to colorless, clear and transparent.

[0065] Deionization: Add the cation exchange resin to the low acyl gellan gum solution at a concentration of 50% (w / v), stir for 60 min, and tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com