A coagulation method for low-temperature turbid water

A turbid water and low temperature technology, applied in the field of coagulation of low temperature turbid water, can solve the problems of low coagulation efficiency and poor purification effect, and achieve the effect of low sediment output, strong applicability and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

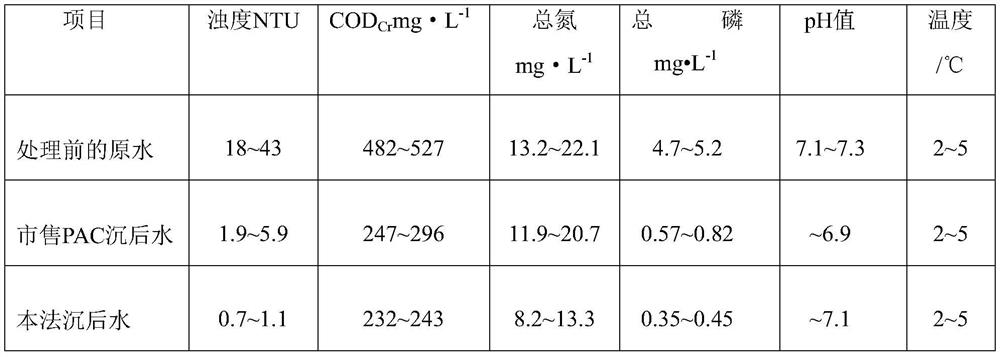

Embodiment 1

[0028] A kind of coagulation method of low-temperature turbid water in the present embodiment, comprises the following steps:

[0029] 1) Prepare a PAM solution with a mass concentration of 0.05%, and the molecular weight of the PAM is more than 3 million;

[0030] 2) Prepare 0.1mol / L ferrous sulfate solution and 0.5mol / L sodium silicate solution, adjust the pH of the sodium silicate solution to 6.0 with concentrated sulfuric acid, and add the above-mentioned ferrous sulfate solution to the above-mentioned sodium silicate solution In the mixed solution, the molar ratio of iron and silicon in the mixed solution is 1:100, and after stirring and aging for 1 to 2 hours, ferrous activated silicic acid is obtained;

[0031] 3) preparation of ferric ion concentration is the polyferric sulfate solution of 0.1mol / L, the degree of alkalinity B=0.5 of the polyferric sulfate solution;

[0032] 4) Take the water of a local lake at 2-5°C as the raw water to be treated, add the PAM solution...

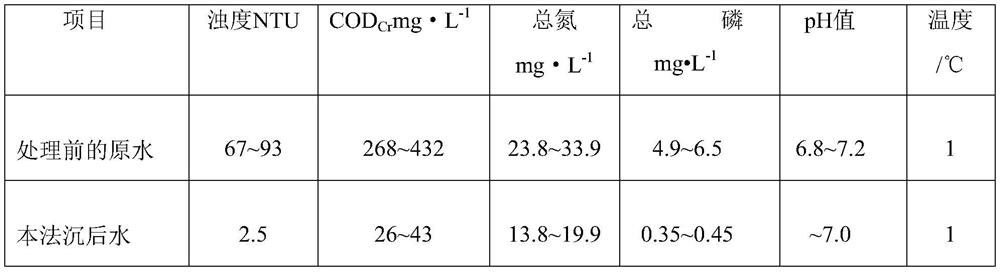

Embodiment 2

[0039] A kind of coagulation method of low-temperature turbid water in the present embodiment, comprises the following steps:

[0040] 1) Prepare a PAM solution with a mass concentration of 0.25%, and the molecular weight of the PAM is more than 3 million;

[0041] 2) Prepare 0.5mol / L ferrous sulfate solution and 1mol / L sodium silicate solution, adjust the pH of the sodium silicate solution to 6.5 with concentrated sulfuric acid, and add the above-mentioned ferrous sulfate solution to the above-mentioned sodium silicate solution , so that the molar ratio of iron and silicon in the mixed solution is 1:300, after stirring and aging for 1 to 2 hours, ferrous activated silicic acid is obtained;

[0042] 3) preparation of ferric ion concentration is the polyferric sulfate solution of 0.5mol / L, the degree of alkalization B=1.0 of the polyferric sulfate solution;

[0043] 4) Select domestic sewage from a community, and after sampling, put the water sample in a freezer at 1°C and sto...

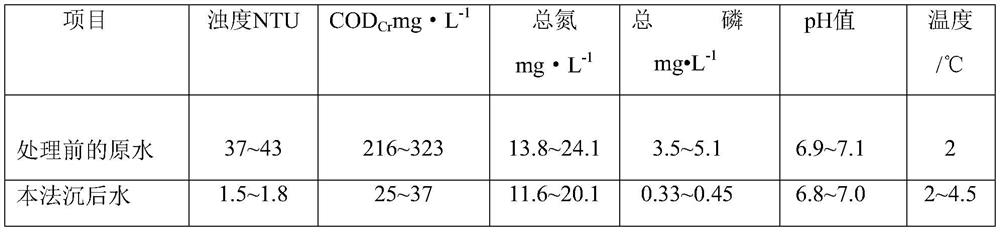

Embodiment 3

[0049] A kind of coagulation method of low-temperature turbid water in the present embodiment, comprises the following steps:

[0050] 1) Prepare a PAM solution with a mass concentration of 0.5%, and the molecular weight of the PAM is more than 3 million;

[0051] 2) Prepare ferrous sulfate solution of 1.0mol / L and sodium silicate solution of 0.1mol / L, adjust the pH of the sodium silicate solution to 6.8 with concentrated sulfuric acid, and add the above-mentioned ferrous sulfate solution to the above-mentioned sodium silicate solution In the mixed solution, the molar ratio of iron and silicon in the mixed solution is 1:200, and after stirring and aging for 1 to 2 hours, ferrous activated silicic acid is obtained;

[0052] 3) preparation of ferric ion concentration is the polyferric sulfate solution of 1mol / L, the degree of alkalinity B=1.5 of the polyferric sulfate solution;

[0053] 4) Select the domestic sewage of a residential area in Jincheng as the raw water to be treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com