Separation device for separating oil from oil-containing mud

A separation device and separation technology, applied in the petroleum industry, sludge treatment, preparation of liquid hydrocarbon mixture, etc., can solve the problems of complex control, large investment, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

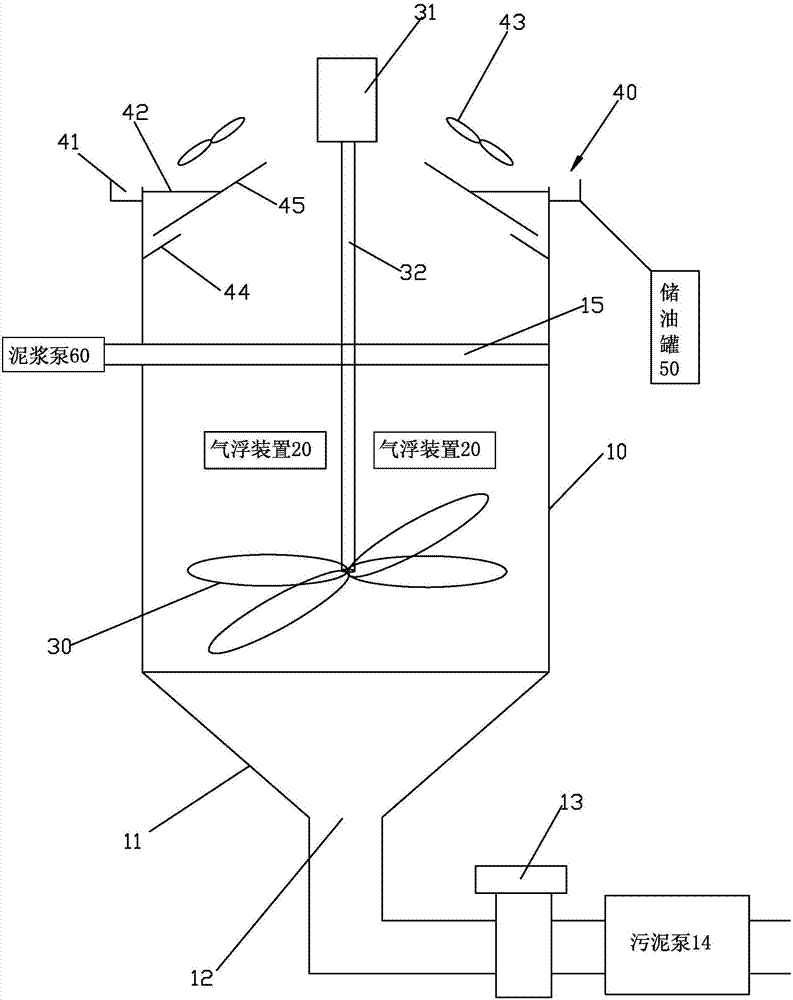

[0021] Please check figure 1 , a separation device for separating oil from oily mud, including a separation tower 10, an air flotation device 20 with a bubble generating device, a stirring impeller 30, a separation unit 40, an oil storage tank 50, a mud pump 60 and an electric control system.

[0022] The separation tower 10 is an open-top container made of metal or plastic material, for example, includes a tower bottom and a tower body extending upward from the periphery of the bottom, and an insulation layer is provided outside the separation tower as required. The middle part of the tower body of the separation tower 10 is provided with a slurry inlet of the separation tower, and the bottom wall of the separation tower 10 is provided with a sludge discharge port 12 of the separation tower. The bottom wall of the separation tower is a conical wall 11 with a large top and a small bottom. The lower port of the conical wall 11 is set as a mud discharge port 12. A mud discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com