Pressure-sensitive polymer compound foam with multi-stage pore structure and preparation method thereof

A composite foam and multi-stage pore technology, which is applied in the measurement of the property and force of piezoelectric resistance materials, etc., can solve the problem of immature pressure-sensitive polymer foam technology that does not have the ability to control foam hierarchical pore structure, high sensitivity hierarchical pore structure, etc. problem, to achieve the effect of wide stress response range, convenient adjustment and high increment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

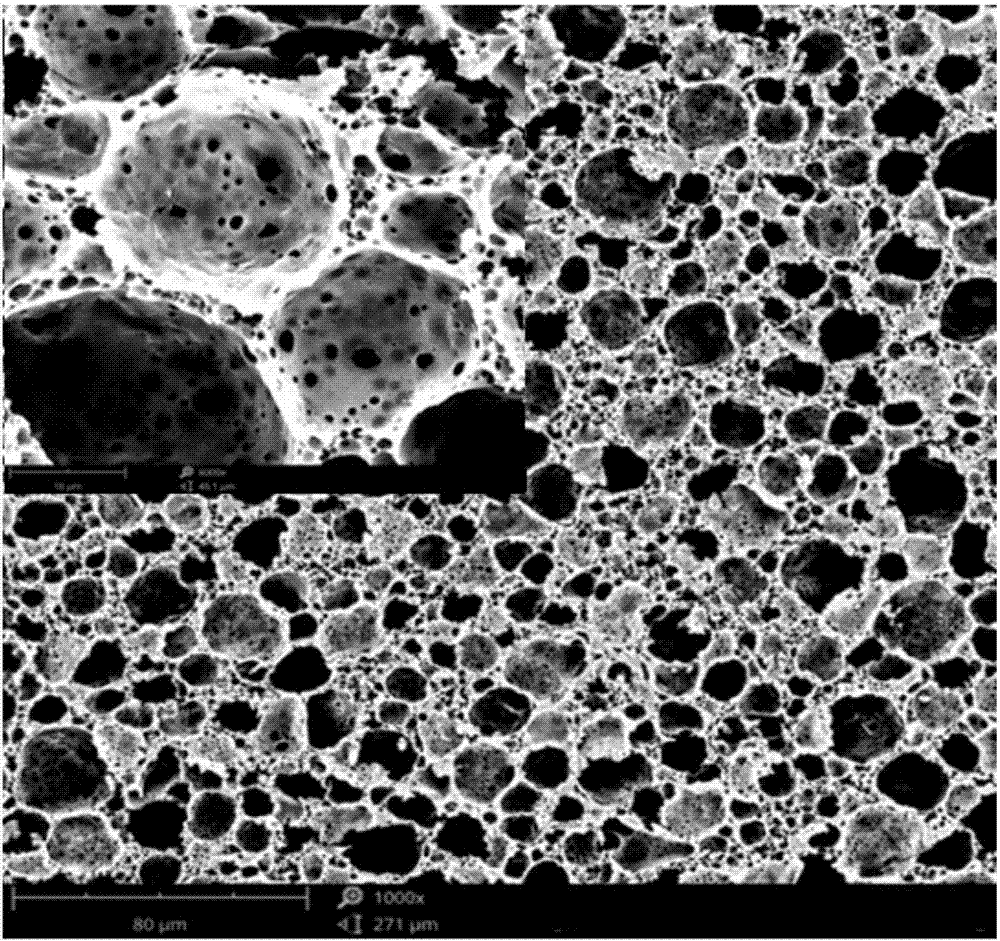

Image

Examples

Embodiment 1

[0051] 1. Preparation of oil phase:

[0052] (1) Mix 0.7 g of methyl methacrylate, 0.4 g of butyl acrylate, 0.3 g of propyl acrylate, 5.67 g of isooctyl methacrylate and 0.81 g of divinylbenzene to obtain a mixed monomer.

[0053] (2) Add 3.5 g of Span 80 and 0.03 g of azobisisobutyronitrile to the mixed monomer obtained in (1), and mix uniformly to obtain an oil phase.

[0054] 2. Preparation of Aqueous Phase

[0055] Add 20 grams of graphene oxide aqueous dispersion (the concentration of graphene oxide aqueous dispersion is 5 mg / g, graphene oxide sheet size is 20 μm), 0.2 gram of ascorbic acid and 0.21 gram of sodium chloride, into 30 mL of deionized water An aqueous phase is obtained. During this period, the ultrasonic method can be used to assist the uniform dispersion of graphene oxide; finally, sodium hydroxide (1M) solution is added dropwise to the filtrate to adjust the pH to 7 for future use.

[0056] 3. Preparation of Pressure Sensitive Foam

[0057] First, pour ...

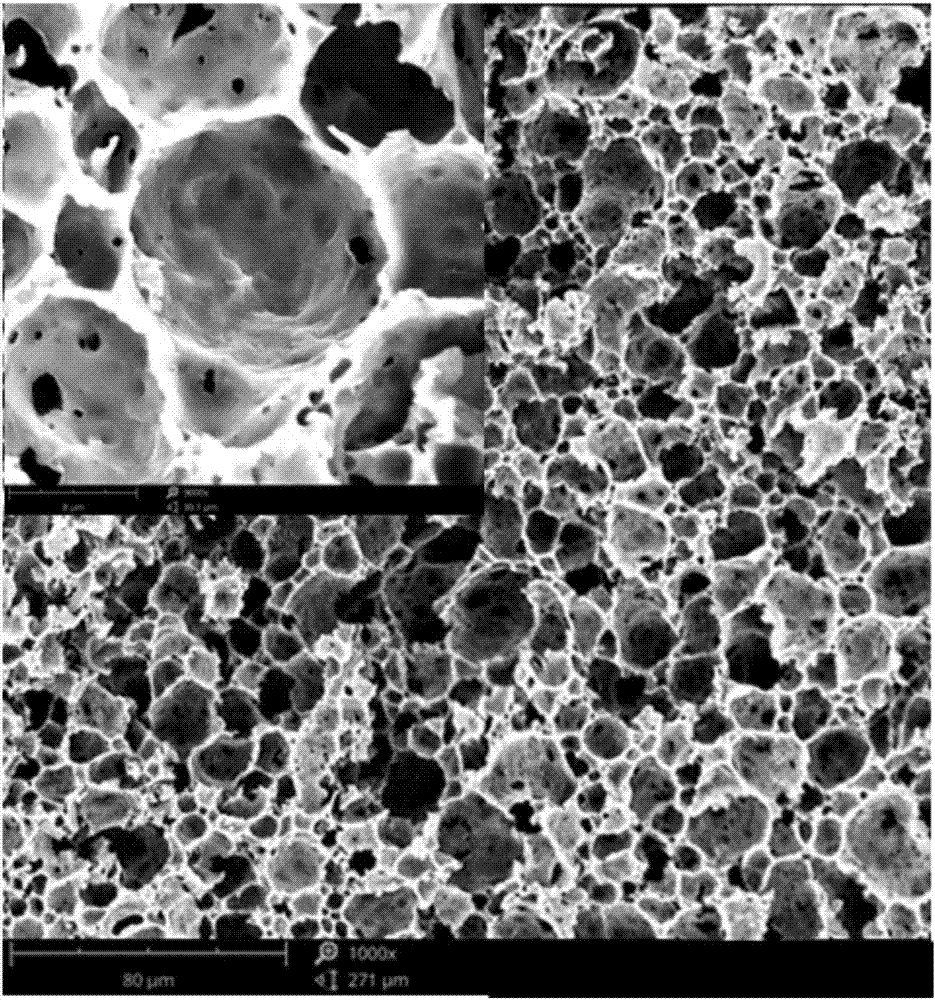

Embodiment 2

[0060] 1. Preparation of oil phase:

[0061] (1) Mix 0.66 g of styrene, 0.68 g of butyl acrylate, 6.88 g of isooctyl methacrylate and 0.9 g of ethylene glycol dimethacrylate to obtain a mixed monomer.

[0062] (2) Add 1 gram of Hypermer A70 and 0.06 gram of azobisisobutyronitrile to the mixed monomer obtained in (1), and mix uniformly to obtain an oil phase.

[0063] 2. Preparation of Aqueous Phase

[0064] Add 20 grams of graphene oxide water dispersion (the concentration of graphene oxide water dispersion is 5 mg / g, graphene oxide sheet size is 100 μm), 0.25 gram of ascorbic acid and 0.3 gram of anhydrous calcium chloride, add to 50 mL of deionized Prepare the aqueous phase in water. During this period, the ultrasonic method can be used to assist the uniform dispersion of graphene oxide; finally, sodium hydroxide (1M) solution is added dropwise to the filtrate to adjust the pH to 6 for future use.

[0065] 3. Preparation of Pressure Sensitive Foam

[0066] First, pour th...

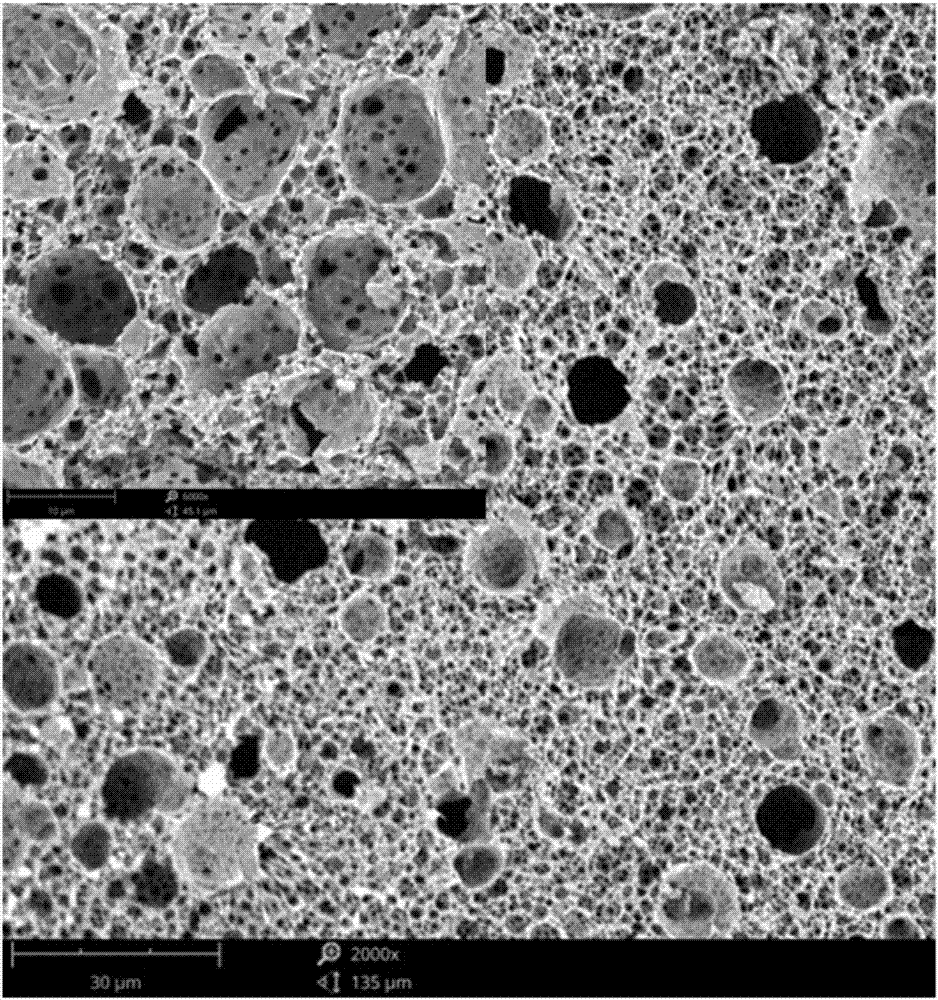

Embodiment 3

[0069] 1. Preparation of oil phase:

[0070] (1) Mix 0.4 g of styrene, 0.68 g of butyl acrylate, 7.23 g of isooctyl methacrylate, and 0.9 g of divinylbenzene to obtain a mixed monomer.

[0071] (2) Add 1.8 g of Hypermer A70 and 0.08 g of benzoyl peroxide to the mixed monomer obtained in (1) and mix evenly to obtain an oil phase.

[0072] 2. Preparation of Aqueous Phase

[0073] 20 grams of graphene oxide aqueous dispersion (the concentration of graphene oxide aqueous dispersion is 1mg / g, graphene oxide sheet size is 2~10 μ m), 0.3 gram of ascorbic acid and 0.2 gram of potassium nitrate, 0.1 gram of sodium nitrate are added to Prepare the aqueous phase with 55 mL of deionized water. During this period, the ultrasonic method can be used to assist the uniform dispersion of graphene oxide; finally, sodium hydroxide (1M) solution is added dropwise to the filtrate to adjust the pH to 8 for later use.

[0074] 3. Preparation of Pressure Sensitive Foam

[0075] First, pour the oil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com