A kind of low molecular weight polyvinyl alcohol self-healing hydrogel and preparation method thereof

A technology of polyvinyl alcohol and low molecular weight, which is applied in the field of polymer biomaterials, can solve the problems of application limitation, limited application, toxicity of complex chemical modification process, etc., and achieve the effect of convenient operation, simple route and excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

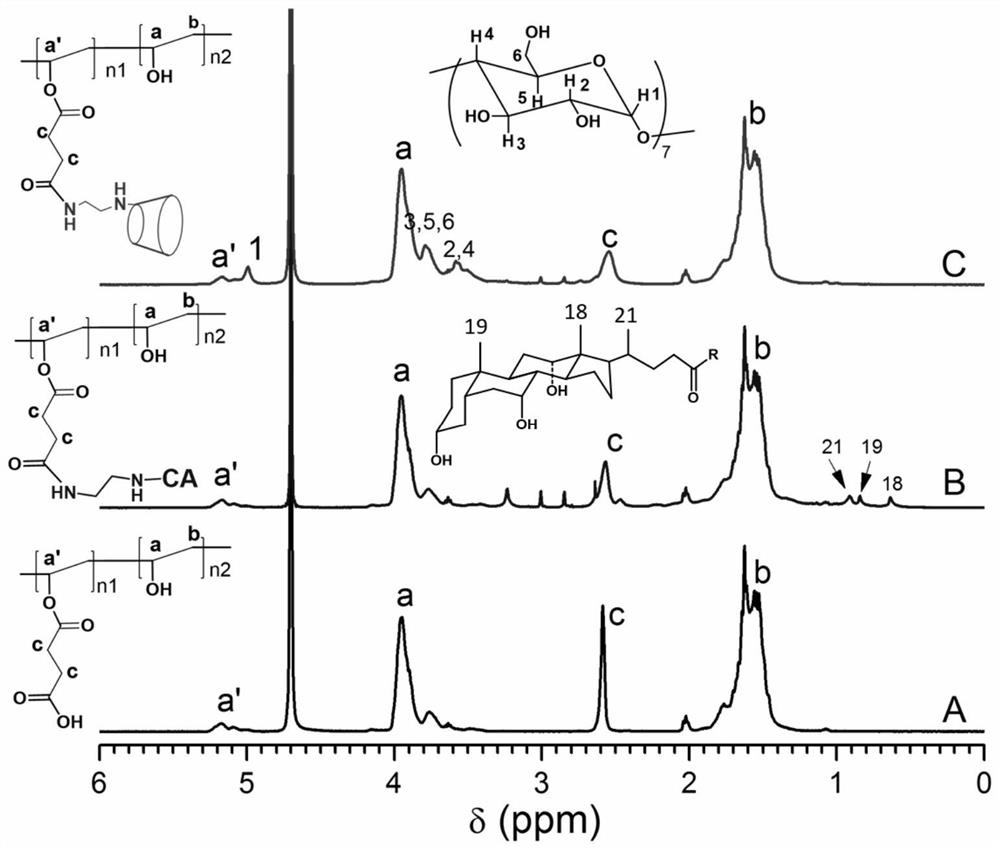

[0036] (1) Preparation of carboxylic acid modified PVA: 4.0g PVA (average Mw: 13000-23000) was dissolved in 20mL dimethylsulfoxide (DMSO) at 80°C, 455mg succinic anhydride (equivalent to PVA hydroxyl molar weight 5%) and 13 mg of p-toluenesulfonic acid (5% of the molar weight of succinic anhydride) were added to the PVA solution as catalysts. The reaction was stirred at 50°C for 48 hours. After the reaction, it was precipitated with ether, and the precipitate was redissolved in an appropriate amount of water, dialyzed for 5 days, and freeze-dried to obtain carboxylic acid-modified PVA.

[0037] (2) Preparation of polyvinyl alcohol PVA-CA grafted with cholic acid: 500 mg of carboxylic acid-modified PVA was dissolved in 10 mL of dimethylformamide (DMF) at 80 ° C, and then 96 mg of amino-modified cholic acid ( cholic acid to anhydride group molar ratio 0.4:1), 53 mg EDC (EDC to cholic acid molar ratio 1.3:1) and 5 mg HOBt (HOBt to cholic acid molar ratio 0.15:1). The mixture wa...

Embodiment 2

[0044] (1) Preparation of carboxylic acid modified PVA: 4.0g PVA (average Mw: 13000-23000) was dissolved in 20mL dimethylsulfoxide (DMSO) at 80°C, 455mg succinic anhydride (equivalent to PVA hydroxyl molar weight 5%) and 7.8 mg of p-toluenesulfonic acid (3% of the molar weight of succinic anhydride) were added as catalysts to the PVA solution. The reaction was stirred at 60°C for 36 hours. After the reaction, it was precipitated with ether, and the precipitate was redissolved in an appropriate amount of water, dialyzed for 5 days, and freeze-dried to obtain carboxylic acid-modified PVA.

[0045] (2) Preparation of polyvinyl alcohol PVA-CA grafted with cholic acid: 500 mg of carboxylic acid-modified PVA was dissolved in 10 mL of dimethylformamide (DMF) at 80 ° C, and then 48 mg of amino-modified cholic acid ( cholic acid to anhydride group molar ratio 0.2:1), 40.8 mg EDC (EDC to cholic acid molar ratio 2:1) and 3.3 mg HOBt (HOBt to cholic acid molar ratio 0.2:1). The mixture ...

Embodiment 3

[0049] (1) Preparation of carboxylic acid modified PVA: 4.0g PVA (average Mw: 13000-23000) was dissolved in 20mL dimethylsulfoxide (DMSO) at 80°C, 455mg succinic anhydride (equivalent to PVA hydroxyl molar weight 5%) and 20.8mg of p-toluenesulfonic acid (equivalent to 8% of the molar amount of succinic anhydride) were added to the PVA solution as catalysts. The reaction was stirred at 40°C for 48 hours. After the reaction, it was precipitated with ether, and the precipitate was redissolved in an appropriate amount of water, dialyzed for 5 days, and freeze-dried to obtain carboxylic acid-modified PVA.

[0050] (2) Preparation of polyvinyl alcohol PVA-CA grafted with cholic acid: 500 mg of carboxylic acid-modified PVA was dissolved in 10 mL of dimethylformamide (DMF) at 80 ° C, and then 72 mg of amino-modified cholic acid ( cholic acid to anhydride group molar ratio 0.3:1), 36.7 mg EDC (EDC to cholic acid molar ratio 1.2:1) and 2.5 mg HOBt (HOBt to cholic acid molar ratio 0.1:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com