High-performance Cu3TmTe3 thermoelectric material and preparation method thereof

A high-performance technology for thermoelectric materials, applied in the field of high-performance Cu3TmTe3 thermoelectric materials and their preparation, can solve the problems of low Seebeck coefficient, high electrical conductivity, high thermal conductivity, etc., achieve simple preparation method, good repeatability, and improve thermoelectric performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

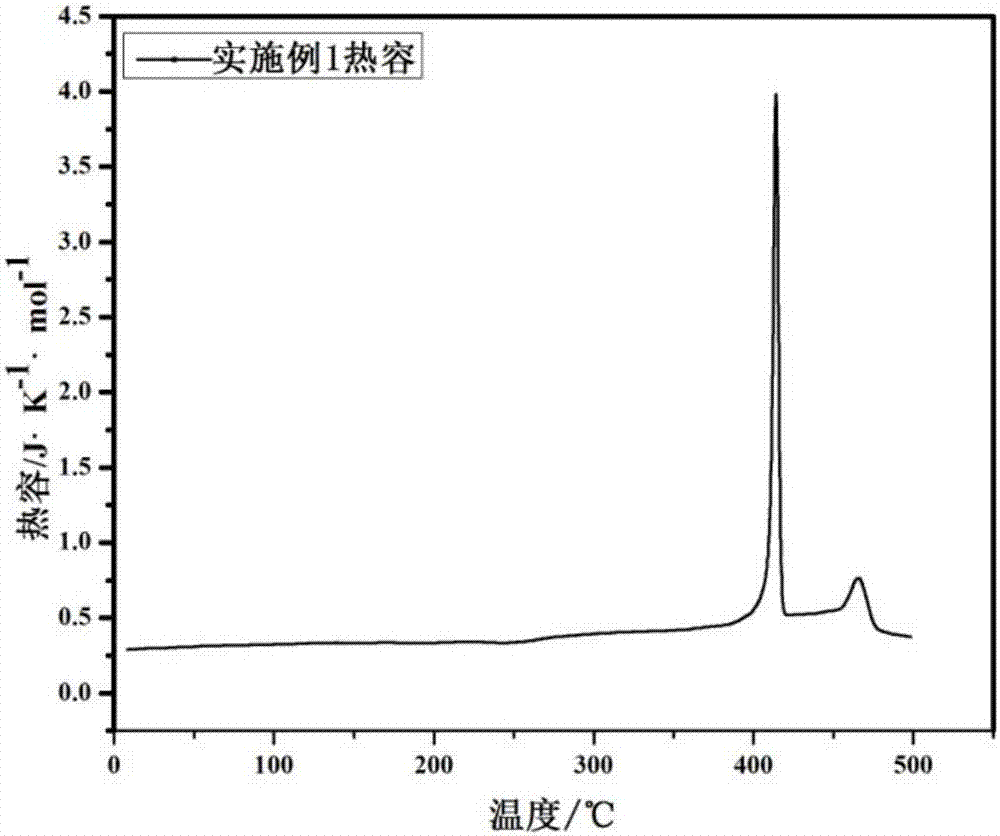

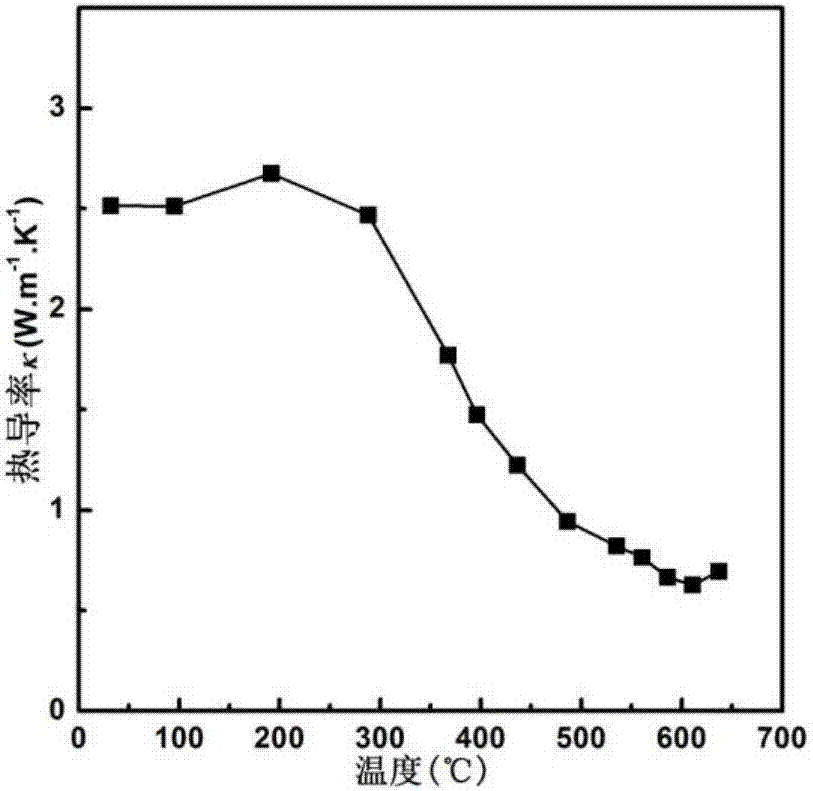

[0049] A high performance Cu 3 TmT 3 Bulk thermoelectric material, its preparation comprises the following steps:

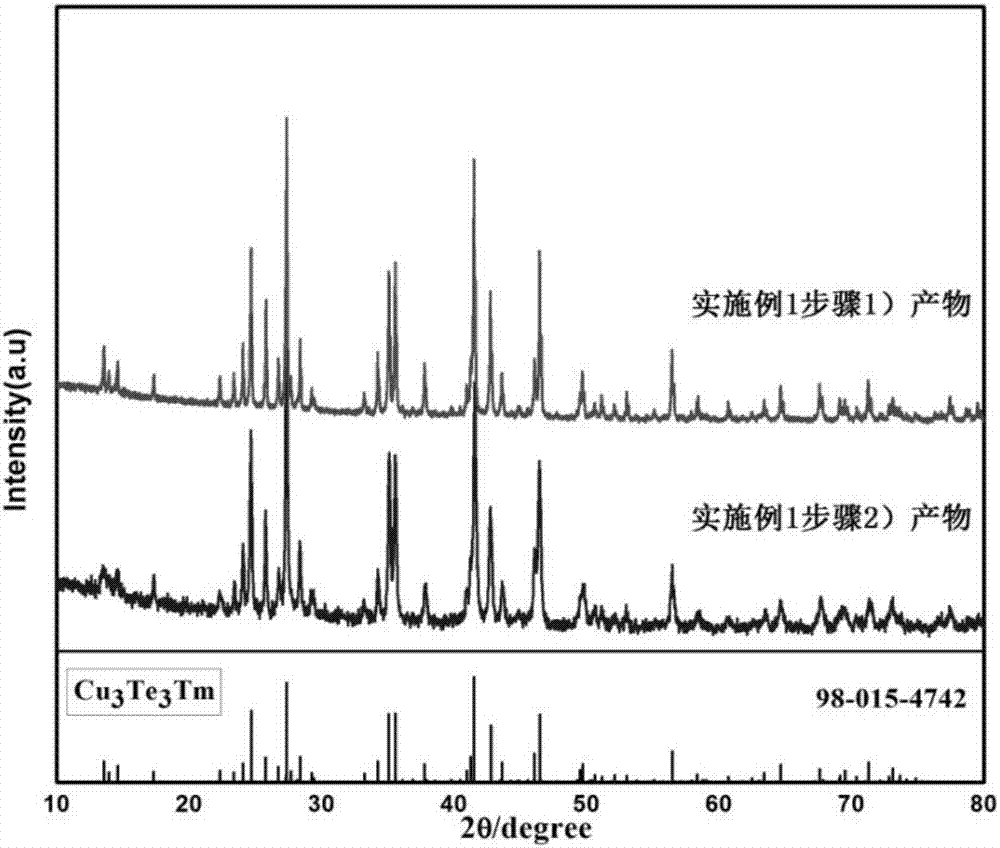

[0050] 1) Melting treatment: take Cu powder, Tm block and Te powder as raw materials, weigh them in a glove box (argon atmosphere) according to a molar ratio of 3:1:3, the total mass of raw materials is about 3g, and then Put the raw materials into the quartz glass tube, vacuum seal the quartz glass tube as soon as possible after taking it out, so that the raw material mixture is in a vacuum atmosphere, then put the quartz glass tube in the melting furnace, raise the temperature to 1150°C within 24 hours and keep it for 48 hours, then The ingot is obtained by cooling in the furnace, and the obtained ingot is ground into a powder in an agate mortar to obtain a single-phase Cu 3 TmT 3 Powder thermoelectric materials;

[0051] 2) Weigh about 1.5g of the obtained Cu 3 TmT 3 Put the powdered thermoelectric material into a Φ10 graphite mold at 10MPa and hold the ...

Embodiment 2

[0058] A high performance Cu 3 TmT 3 Bulk thermoelectric material, its preparation method comprises the following steps:

[0059] 1) Melting treatment: take Cu powder, Tm block and Te powder as raw materials, weigh them in a glove box (argon atmosphere) according to a molar ratio of 3:1:3, the total mass of raw materials is about 3g, and then Put the raw materials into the quartz glass tube, vacuum seal the quartz glass tube as soon as possible after taking it out, so that the raw material mixture is in a vacuum atmosphere, then put the quartz glass tube in the melting furnace, raise the temperature to 1150°C within 24 hours and keep it for 24 hours, then Cooling with the furnace to obtain an ingot, put the obtained ingot into an agate mortar and grind it into powder to obtain a CuTmTe-based powder thermoelectric material;

[0060] 2) Put the CuTmTe-based powder thermoelectric material obtained in step 1) into a Φ10 steel mold for tableting at a pressure of 10 MPa and keep t...

Embodiment 3

[0064] A high performance Cu 3 TmT 3 Bulk thermoelectric material, its preparation comprises the following steps:

[0065] 1) Melting treatment: take Cu powder, Tm block and Te powder as raw materials, weigh them in a glove box (argon atmosphere) according to a molar ratio of 3:1:3, the total mass of raw materials is about 3g, and then Put the raw materials into the quartz glass tube, vacuum seal the quartz glass tube as soon as possible after taking it out, so that the raw material mixture is in a vacuum atmosphere, then put the quartz glass tube in the melting furnace, raise the temperature to 1200°C within 24 hours and keep it for 48 hours, then The ingot is obtained by cooling in the furnace, and the obtained ingot is ground into a powder in an agate mortar to obtain a single-phase Cu 3 TmT 3 Powder thermoelectric materials;

[0066] 2) Weigh about 1.5g of the obtained Cu 3 TmT 3 Put the powdered thermoelectric material into a Φ10 graphite mold at 10MPa and hold the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com