Refrigeration cycle system combining ammonia absorption and injection, and operation method

A circulation system and ammonia water technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of inability to complete deflation, small range of deflation, low coefficient of performance, etc., to alleviate low working performance or even inability to work, Reliable operation and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

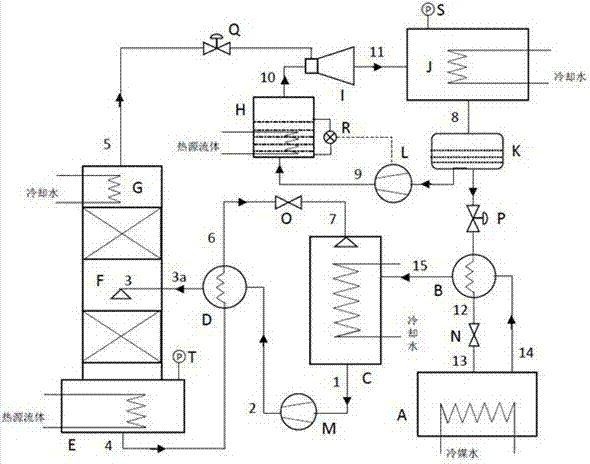

[0029] Embodiment 1: as figure 1 Shown is a refrigeration cycle system that combines the absorption and injection of ammonia water, and the composite refrigeration cycle system includes an evaporator A, a subcooler B, a condenser J, an absorber C, a solution heat exchanger D, and a low-pressure generator E. Rectifier F, decondenser G, high pressure generator H, ejector I, liquid receiver K and solution pumps L, M.

[0030] The concentrated solution outlet of the absorber C of the present invention is connected on the concentrated solution inlet of the solution heat exchanger D through the solution pump M, and the concentrated solution outlet of the solution heat exchanger D is connected with the inlet of the rectifier F, and the top of the rectifier F It is connected to the decondenser G, the bottom of the rectifier F is connected to the low-pressure generator E, the outlet of the dilute solution of the low-pressure generator E is connected to the inlet of the dilute solution ...

Embodiment 2

[0033] Embodiment 2: as figure 1 As shown, a throttling valve N is provided between the liquid outlet of the subcooler B and the inlet of the evaporator A in the present invention, and a throttle valve N is provided between the dilute solution outlet of the solution heat exchanger D and the dilute solution inlet of the absorber C. There is a throttle valve O.

Embodiment 3

[0034] Embodiment 3: as figure 1 As shown, a solenoid valve Q is provided between the outlet of the decondenser G of the present invention and the injection fluid inlet of the ejector I, and a solenoid valve P is provided between the liquid reservoir K and the inlet of the subcooler B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com