Method and device for testing abrasive resistance of optical cable

A test equipment and wear resistance technology, applied in the direction of testing wear resistance, etc., can solve problems such as failure to protect or fix the optical cable well, damage to the structural stability of the optical cable, unstable transmission performance of the optical cable, etc. Economical, reliable and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A single-core optical cable with a sheath with a nominal diameter of 1.8mm requires an abrasion resistance cycle of 1,000,000 times between optical cables, a speed of 10 times / second, and a hanging weight of 1.0kg.

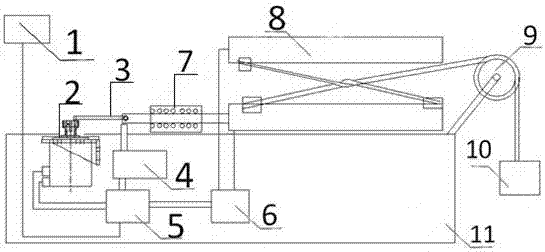

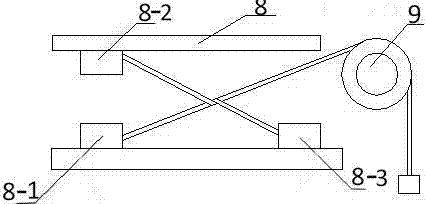

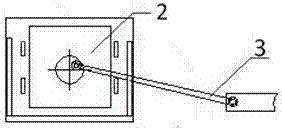

[0026] like figure 1 The equipment shown is tested by first attaching a section of fiber optic cable to the figure 2 Use the two lower clamps to fix it, and then fix one end of the other optical cable with the upper clamp, connect the other end with a 1.0kg weight, wrap around the lower fixed optical cable and place it on the fixed pulley. The placed optical cable sample should be and figure 2 unanimous.

[0027] The equipment starts, enters the operation screen 10 of the man-machine interface, and the state of the motor of the private server is set to run. Enter the parameter setting, set the speed to 10 times per second, set the disconnection function to non-stop when disconnected, set the number of actions to 1,000,000 times, return to the display i...

Embodiment 2

[0029] A kind of secondary buffer layer 62.5 / 125μm multimode optical fiber cable, the diameter of the optical cable is 0.9mm, the abrasion resistance cycle between optical cables is required to be 10000 times, the speed is 10 times / second, the hanging weight is 2.2N, and it is fixed around the bottom Place the optical cable on the fixed pulley after one lap, and the placed optical cable sample should be the same as figure 2 unanimous.

[0030] like figure 1 The equipment shown is tested by first attaching a section of fiber optic cable to the figure 2Use the two lower clamps to fix it, and then fix one end of the other optical cable with the upper clamp, and connect the other end to a 2.2N weight, and place it on the fixed pulley after wrapping around the lower fixed optical cable. The placed optical cable sample should be and figure 2 unanimous.

[0031] The equipment starts, enters the operation screen 10 of the man-machine interface, and the state of the motor of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com