Gas detection sheet and electrochemical element with gas detection sheet

An electrochemical component and gas detection technology, applied in electrical components, electrochemical generators, circuits, etc., can solve the problem of not being able to specify the location of gas leakage, and achieve the effect of excellent visibility and good sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

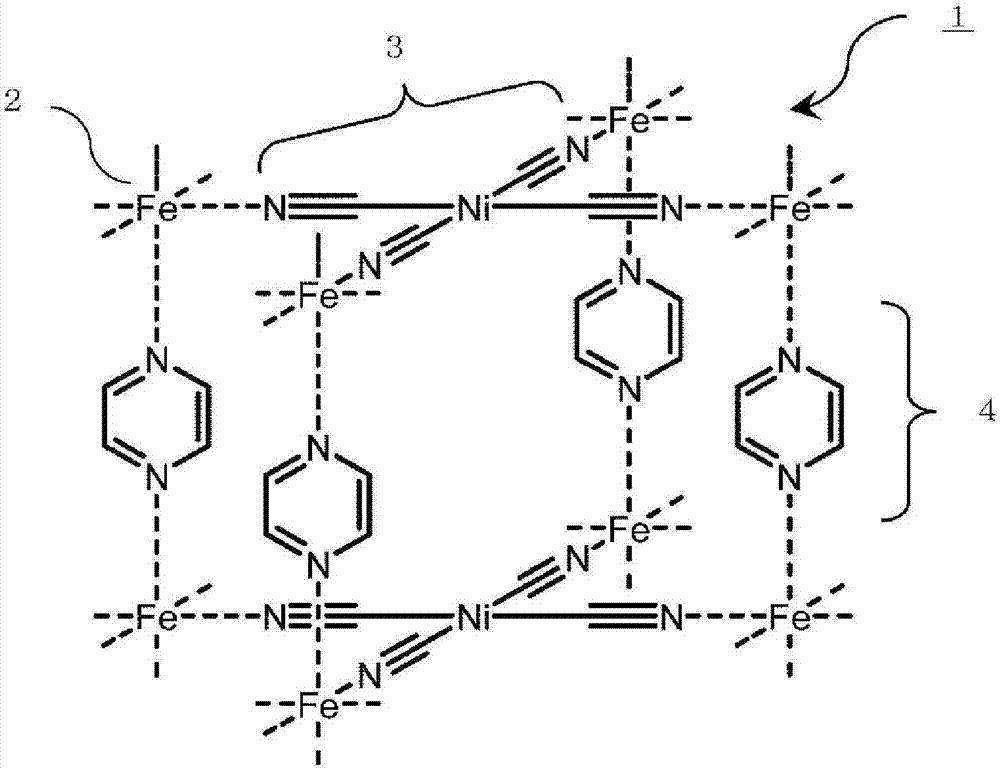

[0061] (Manufacture of porous coordination polymers)

[0062] Add 0.24 g of iron ammonium sulfate (II) hexahydrate, 0.1 g of L-ascorbic acid, and 0.15 g of potassium tetracyanonickelate (II) monohydrate to 240 mL of a mixed solvent of distilled water and ethanol in a Erlenmeyer flask, and stir , recovering the precipitated intermediate particles. 0.1 g of the obtained intermediate particles were dispersed in ethanol, and 0.10 g of pyrazine was added over 30 minutes. The deposited precipitate was filtered and dried at 120° C. for 3 hours in the air to obtain an orange porous coordination polymer.

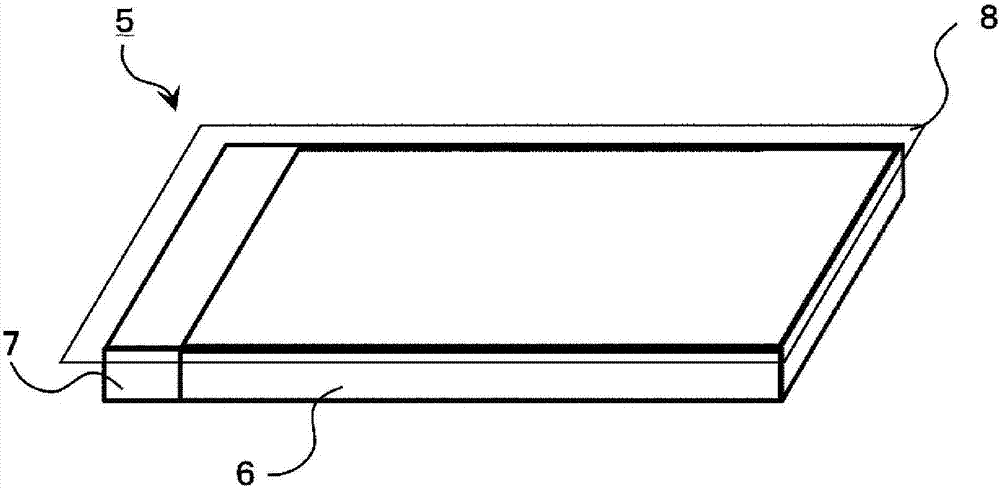

[0063] (Manufacture of gas detection sheet)

[0064] After immersing the porous coordination polymer of Example 1 in acetonitrile at 25° C. for 10 hours, suction filtration was performed using filter paper 5 types C and dried, thereby obtaining a purple-red color on filter paper 5 types C. Porous coordination polymers. The spin state of the obtained purple-red porous coordination...

Embodiment 2~5 and comparative example 1 and 2

[0078] In addition to using roll papers with different air permeability, and the loading amount of porous coordination polymer per unit area of the gas detection sheet is 0.1mg / cm 2 A gas detection sheet was produced in the same manner as in Example 1, except that the concentration of the dispersion solution of the porous coordination polymer was changed. Table 1 shows the air permeability of the gas detection sheet obtained in the same manner as in Example 1 and the time when the color tone of the gas detection sheet in the DEC gas detection test was visually confirmed.

[0079] [Table 1]

[0080]

[0081] (Detection of diethyl carbonate gas)

[0082] The gas detection sheets of Examples 2 to 5 were evaluated in the same manner as in Example 1 for color tone change due to DEC gas, and as a result, it was confirmed that the gas detection sheets changed to orange. The gas detection sheets of Comparative Example 1 and Comparative Example 2 were evaluated for color tone ch...

Embodiment 6~15、 comparative example 3~5

[0086] In addition to weighing ammonium iron sulfate (II) hexahydrate, potassium tetracyano nickelate (II) monohydrate, potassium tetracyanopalladate hydrate, and potassium tetracyanoplatinate so that the composition described in Table 2 Except for the hydrate, a porous coordination polymer was produced in the same manner as in Example 1, except that the loading amount of the porous coordination polymer per unit area of the gas detection chip was 0.1 mg / cm 2 A gas detection sheet was produced in the same manner as in Example 1, except that the concentration of the dispersion solution of the porous coordination polymer was changed. Table 2 shows the air permeability of the gas detection sheet obtained in the same manner as in Example 1 and the time when the color tone of the gas detection sheet in the DEC gas detection test was visually confirmed.

[0087] [Table 2]

[0088]

[0089] (Detection of diethyl carbonate gas)

[0090] Regarding the gas detection sheets of Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com