Micro-current measuring circuit for dielectric response test

A technology for measuring circuit and dielectric response, applied in the direction of only measuring current, measuring electrical variables, measuring current/voltage, etc. Radiation and high-frequency radiation interference, inability to measure current signals in the frequency range, etc., to achieve the effect of not easy to be affected by external temperature, suppress power frequency and radiation interference, and have high test stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

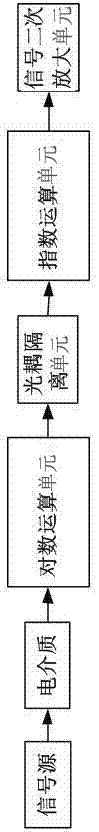

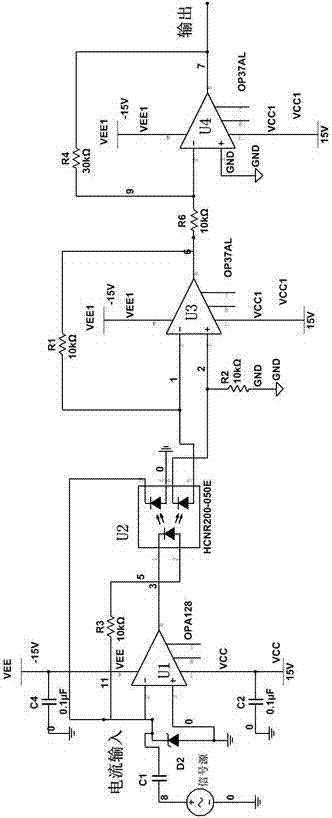

[0019] A microcurrent measurement circuit for dielectric response testing, comprising a logarithmic operation unit, a linear optocoupler unit, an exponential operation unit, and a signal secondary amplification unit, the logarithmic operation unit, a linear optocoupler unit, and an exponential operation unit and the signal secondary amplification unit are connected successively.

[0020] The logarithmic operation unit includes an amplifier with an ultra-low bias current and a negative feedback element, the linear optocoupler unit includes a linear optocoupler chip and a negative feedback circuit, and the exponential operation unit includes a high-speed operational amplifier and a photosensitive diode.

Embodiment 2

[0022] A microcurrent measurement circuit for dielectric response testing, comprising a logarithmic operation unit, a linear optocoupler unit, an exponential operation unit, and a signal secondary amplification unit, the logarithmic operation unit, a linear optocoupler unit, and an exponential operation unit and the signal secondary amplification unit are connected successively.

[0023] The logarithmic operation unit includes an amplifier with an ultra-low bias current and a negative feedback element, the linear optocoupler unit includes a linear optocoupler chip and a negative feedback circuit, and the exponential operation unit includes a high-speed operational amplifier and a photosensitive diode.

[0024] The amplifier with ultra-low bias current is OPA128.

Embodiment 3

[0026] A microcurrent measurement circuit for dielectric response testing, comprising a logarithmic operation unit, a linear optocoupler unit, an exponential operation unit, and a signal secondary amplification unit, the logarithmic operation unit, a linear optocoupler unit, and an exponential operation unit and the signal secondary amplification unit are connected successively.

[0027] The logarithmic operation unit includes an amplifier with an ultra-low bias current and a negative feedback element, the linear optocoupler unit includes a linear optocoupler chip and a negative feedback circuit, and the exponential operation unit includes a high-speed operational amplifier and a photosensitive diode.

[0028] The ultra-low bias current amplifier is OPA128.

[0029] The model of the linear optocoupler chip is HCNR201.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com