Ultrahigh-voltage power cable with smooth aluminum sheath

A technology for power cables and aluminum sheaths, which is applied in the field of smooth aluminum sheathed ultra-high voltage power cables, can solve problems such as breakdown, poor electrical contact, corrosion of aluminum sheaths, etc., to reduce material loss, ensure cable operation safety, Effect of reducing the outer diameter of the cable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

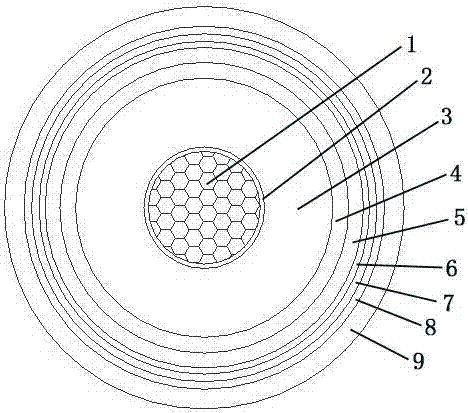

[0020] Such as figure 1 As shown, a smooth aluminum sheathed extra-high voltage power cable includes a conductor 1, a three-layer co-extruded inner shielding layer 2, an insulating layer 3 and an insulating shielding layer 4 outside the conductor; a semi-conductive buffer resistor is provided outside the insulating shielding layer The water belt 5 is provided with a smooth aluminum metal sheath 6 outside the semi-conductive buffer water blocking belt, coated with an anti-corrosion asphalt layer 7 outside the smooth aluminum metal sheath, and has a non-metallic sheath 8 outside the anti-corrosion asphalt layer. A graphite coating 9 is provided outside the layer.

[0021] The invention improves the structure of the metal sheath, changes the commonly used longitudinal welded embossed structure into a smooth aluminum sheath without embossing, makes the semi-conductive buffer l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com