a kind of al 2 o 3 and fe 3 o 4 Method for composite catalytic pyrolysis of waste circuit board non-metallic powder

A waste circuit board, catalytic pyrolysis technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

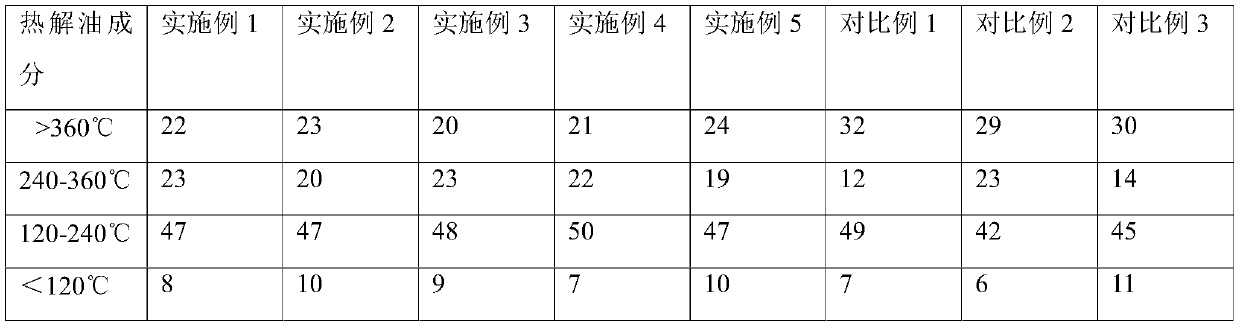

Examples

Embodiment 1

[0021] A kind of composite catalyst, by the Al of 40 parts by weight 2 o 3 and 60 parts by weight of Fe 3 o 4 composition.

[0022] a kind of Al 2 o 3 and Fe 3 o 4 The method for composite catalytic pyrolysis of waste circuit board non-metallic powder comprises the following steps: S1. breaking the waste circuit board, extracting non-metallic powder, putting the non-metallic powder into the first temperature zone of the two-stage heating pyrolysis furnace, and simultaneously Put the composite catalyst into the second temperature zone of the two-stage heating pyrolysis furnace. S2. The first temperature zone and the second temperature zone are heated at the same time. The heating condition in the second temperature zone is to heat to 500°C, keep it for 2 hours, and collect the pyrolysis oil after complete pyrolysis; the weight ratio of non-metallic powder to composite catalyst is 1:1.

Embodiment 2

[0024] A kind of composite catalyst, by the Al of 45 parts by weight 2 o 3 and 55 parts by weight of Fe 3 o 4 composition.

[0025] a kind of Al 2 o 3 and Fe 3 o 4 The method for composite catalytic pyrolysis of waste circuit board non-metallic powder comprises the following steps: S1. breaking the waste circuit board, extracting non-metallic powder, putting the non-metallic powder into the first temperature zone of the two-stage heating pyrolysis furnace, and simultaneously Put the composite catalyst into the second temperature zone of the two-stage heating pyrolysis furnace. S2. The first temperature zone and the second temperature zone are heated at the same time. The heating condition in the second temperature zone is to heat to 520°C and keep it for 2.2 hours, and collect the pyrolysis oil after complete pyrolysis; the weight ratio of non-metallic powder to composite catalyst is 1.5:1.

Embodiment 3

[0027] A kind of composite catalyst, by the Al of 50 parts by weight 2 o 3 and 50 parts by weight of Fe 3 o 4 composition.

[0028] a kind of Al 2 o 3 and Fe 3 o 4 The method for composite catalytic pyrolysis of waste circuit board non-metallic powder comprises the following steps: S1. breaking the waste circuit board, extracting non-metallic powder, putting the non-metallic powder into the first temperature zone of the two-stage heating pyrolysis furnace, and simultaneously Put the composite catalyst into the second temperature zone of the two-stage heating pyrolysis furnace. S2. The first temperature zone and the second temperature zone are heated at the same time. The heating condition of the first temperature zone is to heat to 470 ° C and keep it for 1.7 hours. The heating condition in the second temperature zone is to heat to 540°C and keep it for 2.4 hours, and collect the pyrolysis oil after complete pyrolysis; the weight ratio of non-metallic powder to composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com