Preparation method of thin-gauge non-oriented silicon steel with high magnetic induction and low iron loss based on thin strip continuous casting

A technology of oriented silicon steel and high magnetic induction, applied in the field of metallurgy, can solve the problems of hindered industrial production and poor processing performance of high silicon steel, and achieve the effects of improving the uniformity of the structure, improving the formability and improving the yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

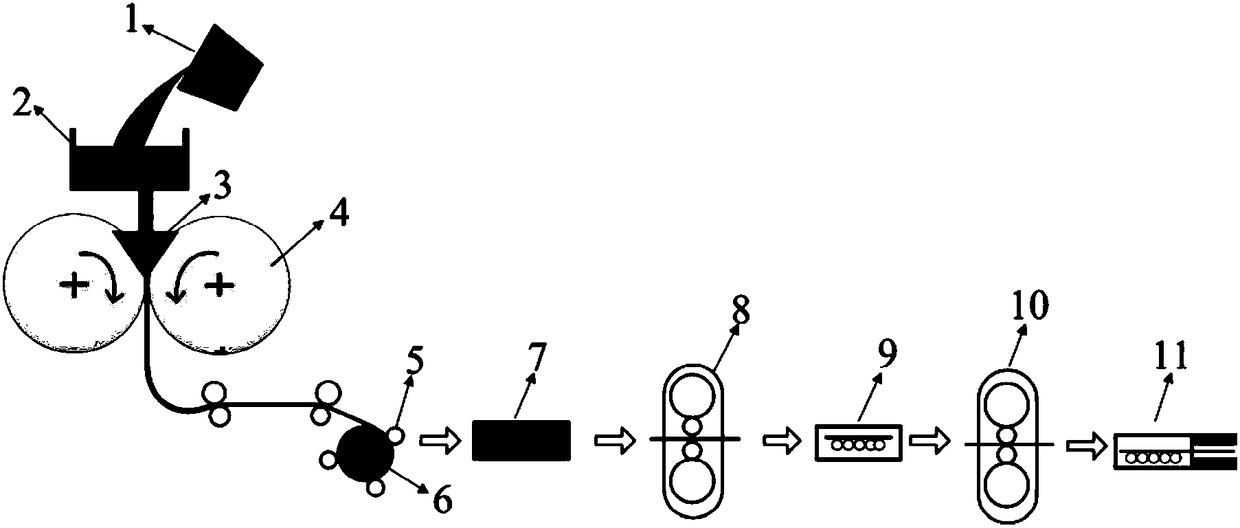

Embodiment 1

[0035] In this embodiment, according to the chemical composition (mass percentage) C 0.004%, Si 2.9%, Mn 0.005%, Al 0.15%, P 0.03%, S 0.003%, N 0.003%, O 0.003%, the rest is Fe and not Avoid impurities and smelt molten steel. The molten steel casting temperature is controlled at 1530°C, cast and rolled into a 2.2mm thick cast strip by a thin strip continuous casting machine, and the casting speed is 8m / min. After the cast strip comes out of the roll, it is cooled to 720°C at a speed of about 30°C / s for curling, and then cooled to room temperature. The proportion of columnar crystals in the cast strip is 73%. After being pickled with 110g / L hydrochloric acid at 75°C, warm rolling is carried out three times. The warm rolling temperature is 200°C, the total reduction rate is 45%, and the pass reduction is 14-17%. Then carry out two passes of cold rolling, the total reduction rate is 42%, and the pass reduction rate is 18-24%. then in N 2Intermediate annealing was carried out a...

Embodiment 2

[0038] In this embodiment, according to the chemical composition (mass percentage) C 0.003%, Si 3.0%, Mn 0.1%, Al 0.2%, P 0.03%, S 0.003%, N 0.003%, O 0.003%, the rest is Fe and cannot Avoid impurities and smelt molten steel. The casting temperature of the molten steel is controlled at 1530°C, cast and rolled into a 2.0mm thick cast strip with a thin strip continuous casting machine, and the casting speed is 7m / min. After the cast strip comes out of the roll, it is cooled to 700°C at a speed of about 30°C / s for curling, and then cooled to room temperature. The proportion of columnar crystals in the cast strip is 75%. After being pickled with 110g / L hydrochloric acid at 75°C, warm rolling is carried out three times. The warm rolling temperature is 200°C, the total reduction rate is 50%, and the reduction amount of each pass is 15-20%. Then carry out three passes of cold rolling, the total reduction rate is 53%, and the pass reduction rate is 15-23%. then in N 2 Intermediate ...

Embodiment 3

[0041] In this embodiment, according to the chemical composition (mass percentage) C 0.004%, Si 2.8%, Mn 0.04%, Al 0.4%, P 0.04%, S 0.003%, N 0.003%, O 0.003%, the rest is Fe and cannot Avoid impurities and smelt molten steel. The molten steel casting temperature is controlled at 1540°C, cast and rolled into a 2.1mm thick cast strip by a thin strip continuous casting machine, and the casting speed is 10m / min. After the cast strip comes out of the roll, it is cooled to 740°C at a speed of about 30°C / s for curling, and then cooled to room temperature. The proportion of columnar crystals in the cast strip is 79%. After pickling with 140g / L hydrochloric acid at 80°C, three passes of warm rolling are carried out. The warm rolling temperature is 200°C, the total reduction rate is 47%, and the pass reduction is 14-19%. Then carry out three passes of cold rolling, the total reduction rate is 68%, and the pass reduction rate is 15-25%. then in N 2 Intermediate annealing was carried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com