Multilayer composite structure rare earth barium copper oxide superconducting film and preparation method thereof

A rare earth barium copper oxide and multi-layer composite technology, which is applied in the direction of cable/conductor manufacturing, equipment for manufacturing conductive/semiconductive layers, electrical components, etc., can solve the disadvantages of low-cost preparation and the thickness-dependent effect mechanism of critical current density not very clear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

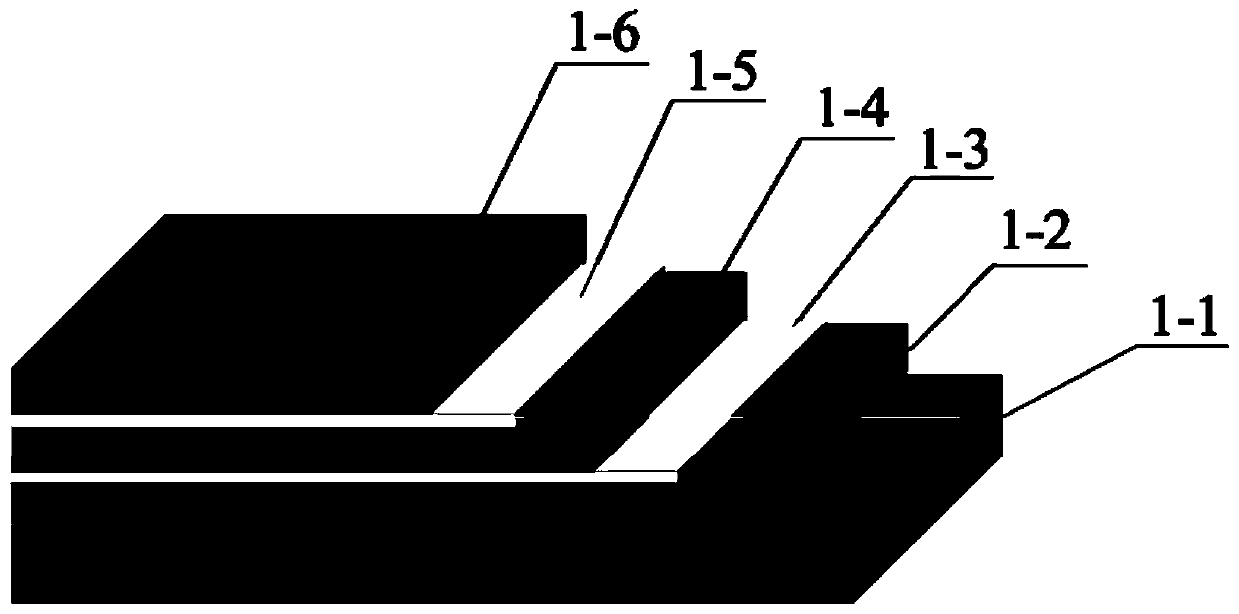

[0030] refer to Figure 1 to Figure 8 , in one embodiment, a method for preparing a rare earth barium copper oxide high temperature superconducting film of a multilayer composite structure, comprising: alternately depositing REBa on a substrate 1+x CuO 7-y film and metal layer, the formed superconducting film is expressed as (REBa 1+ x CuO 7-y / M)n, where RE is a rare earth element, M represents the metal layer, 0.5≤x≤1, 01+x CuO 7-y Use chemical solution coating, the precursor used in the chemical solution coating contains salts of rare earth metals, barium and copper, the metal layer is deposited by physical vapor phase, and the multilayer composite structure of rare earth barium copper is obtained after heat treatment Oxygen superconducting film.

[0031] The present invention addresses the critical current density thickness dependence effect of the key problem in the preparation of superconducting films, and proposes a new process idea: using physical vapor deposition...

example 1

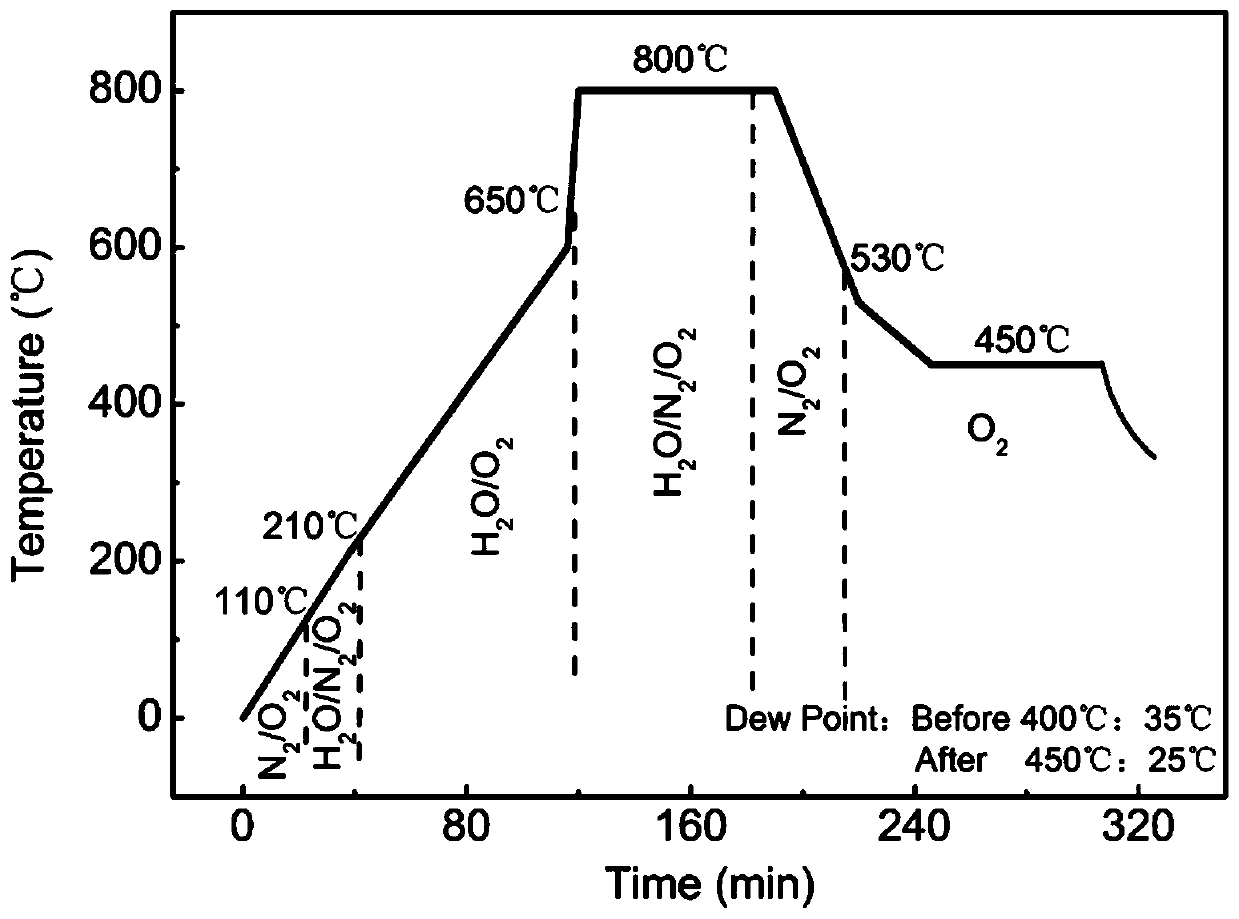

[0053] The preparation process is as figure 2 As shown, first according to the metal cation molar ratio of 1:(1+x):3 (where 0.5≤x≤1), yttrium acetate tetrahydrate, gadolinium acetate, barium acetate, and copper acetate monohydrate were dissolved by stirring in deionized water, and added trifluoroacetic acid to it. After two rotary vacuum evaporation processes, the above-mentioned metal salt was finally dissolved in methanol to obtain a clear, transparent, dark blue precursor precursor. The total concentration of metal elements in the precursor solution is 0.5-3mol / L. The precursor solution is coated by spin coating-ion beam deposition-spin coating multiple times, and no pyrolysis is required during the coating process, which avoids the erosion of the pyrolytic film by water vapor. On this basis, we prepared (Y 0.9 Gd 0.1 Ba 1.5 Cu 3 o 7-δ ) x / Au y Multilayer film, the schematic diagram of which is shown in figure 1 1-1 in the figure represents the substrate, which ...

example 2

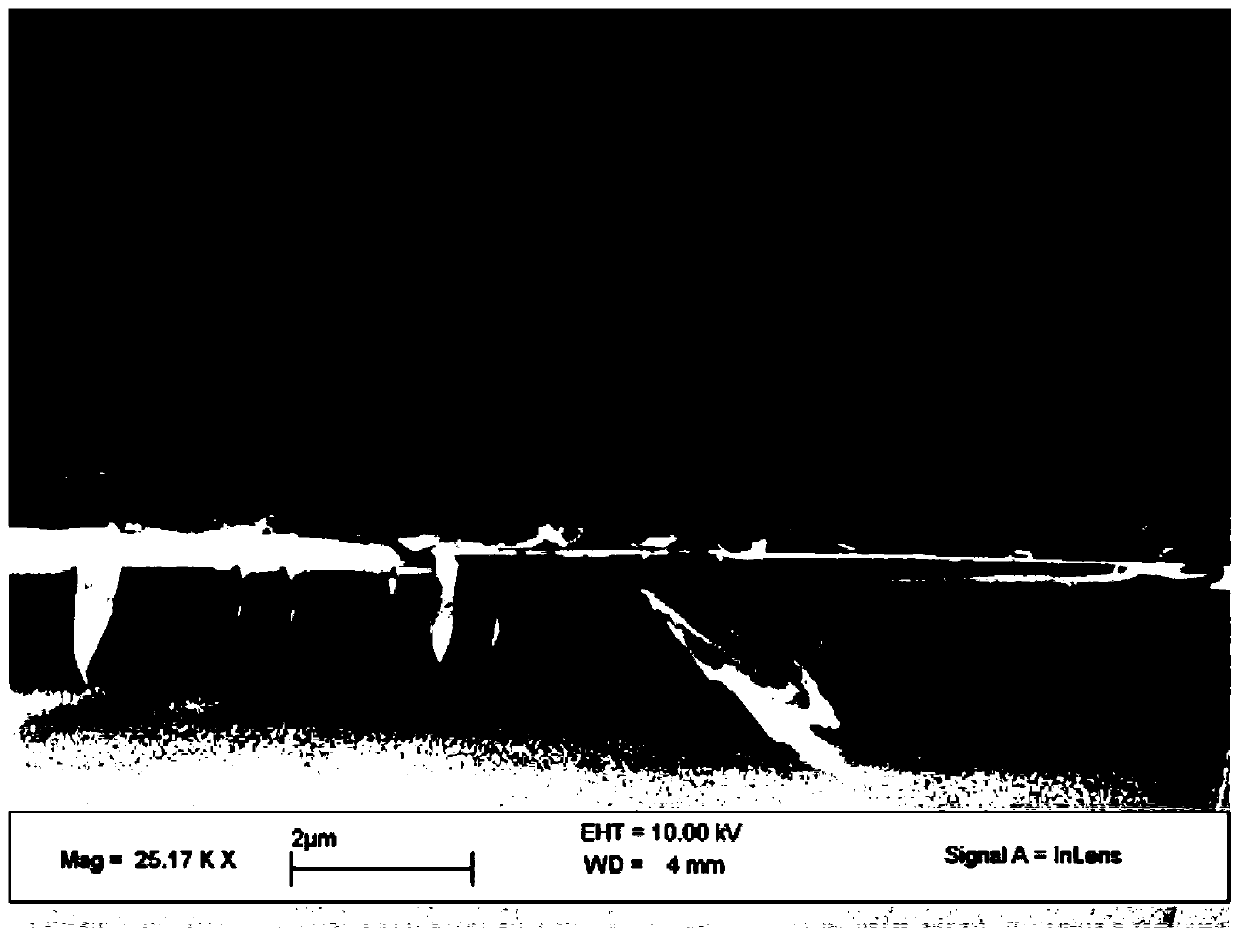

[0055] Prepare according to the step in example 1 (Y 0.9 Gd 0.1 Ba 1.5 Cu 3 o 7-δ ) 3 / (Au) 2 Five-layer film samples. From Figure 5 It can be seen from the cross-sectional picture that the thickness of the sample is greater than 1.1 μm, and the critical current density obtained by measuring the AC magnetic susceptibility reaches 1.3MA / cm 2 . pass Figure 6 , XRD measurements found that Au ions basically did not replace Y 0.9 Gd0.1 Ba 1.5 Cu 3 o 7-δ The metal ions in the metal ions mainly exist in the form of elemental Au.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com