A method for obtaining gh4169 alloy ultra-fine grain forging

A GH4169, ultra-fine grain technology, applied in the field of forging, can solve the problems of uneven and fine structure, difficulty in obtaining ultra-fine grain structure, uneven structure, etc., and achieve the effect of fine and uniform structure of forgings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

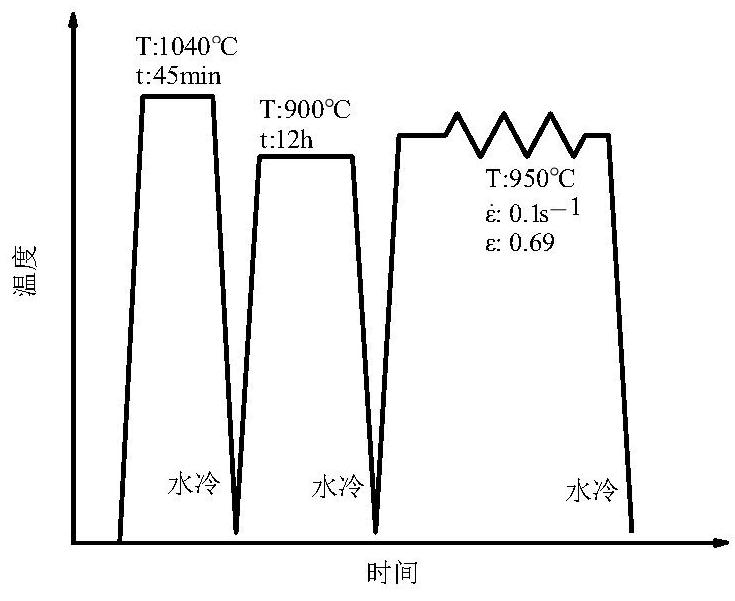

[0024] Step 1: The GH4169 alloy forging billet is subjected to solution treatment and aging treatment successively, the solution temperature is 1040±5°C, the solution time is 45min, the aging temperature is 900±5°C, and the aging time is 12h. Water quenching is carried out on the forged billet after solid solution and aging treatment respectively;

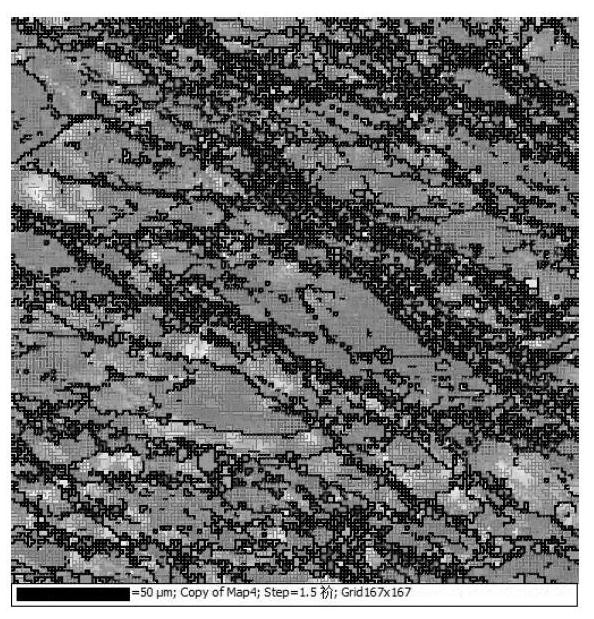

[0025] Step 2: Heat the GH4169 alloy forging billet processed in step 1 to the deformation temperature and hold it for 5 minutes, then perform upsetting thermal deformation, the deformation temperature is 950±5°C, and the strain rate is 0.1s -1 , the amount of deformation is 50% (equivalent to 0.69), and the forging is water quenched immediately after the deformation. The processing route of GH4169 alloy forging blank through steps 1 and 2 is as follows figure 1 As shown, the deformed structure after forging is as follows figure 2 shown;

[0026] Step 3: Perform delta phase aging treatment on the forging obtained in step 2, the...

Embodiment 2

[0030]Step 1: The GH4169 alloy forging billet is subjected to solution treatment and aging treatment successively, the solution temperature is 1040±5°C, the solution time is 45min, the aging temperature is 900±5°C, and the aging time is 12h. Water quenching is carried out on the forged billet after solid solution and aging treatment respectively;

[0031] Step 2: Heat the GH4169 alloy forging billet processed in step 1 to the deformation temperature and hold it for 5 minutes, then perform upsetting thermal deformation, the deformation temperature is 950°C, and the strain rate is 0.1s -1 , the amount of deformation is 50% (equivalent to 0.69), and the forging is water quenched immediately after the deformation;

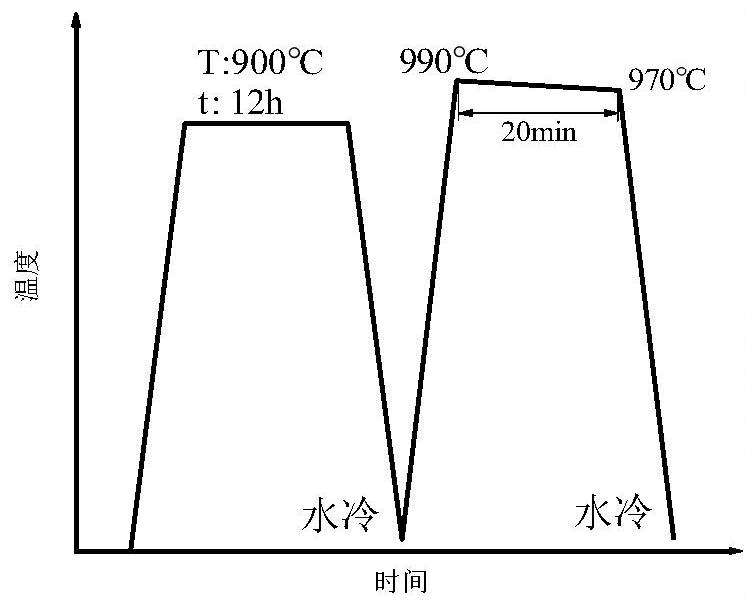

[0032] Step 3: Perform aging treatment on the forging obtained in step 2, the aging temperature is 900±5°C, the aging time is 12h, and then water quenching;

[0033] Step 4: Perform continuous cooling annealing on the GH4169 forging obtained in step 3. The initial ann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com