Device for achieving power station peak load regulation with molten salt heat storage and working method thereof

A molten salt and low-temperature molten salt technology, applied in steam engine installations, steam applications, machines/engines, etc., can solve problems such as uneconomical and inability to cope with power station systems, and achieve low cost, reduce the number of tanks, and have little impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0030] Example.

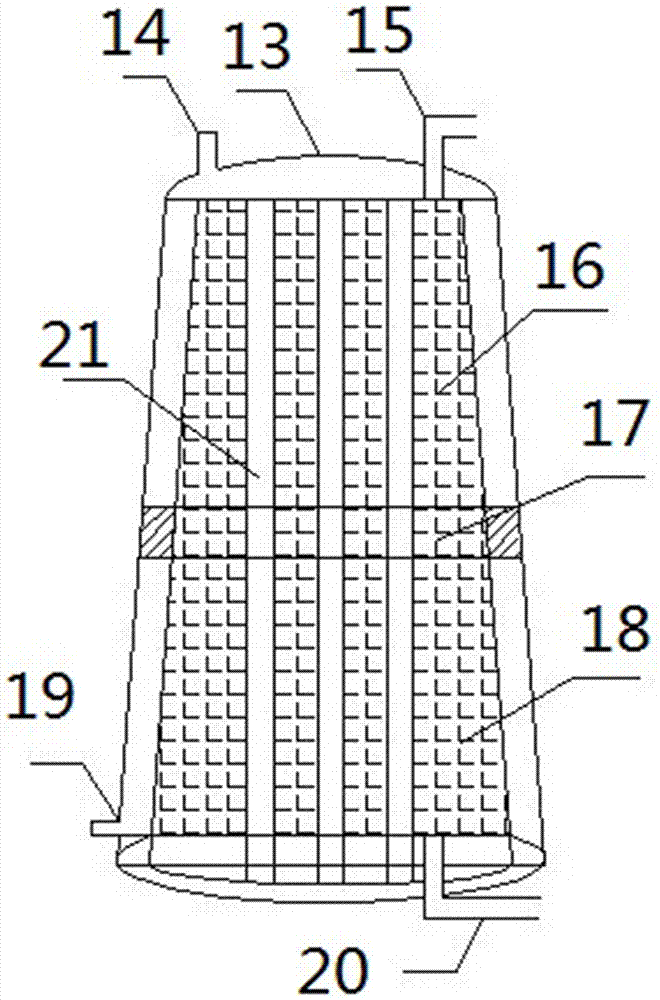

[0031] see Figure 1 to Figure 4 .

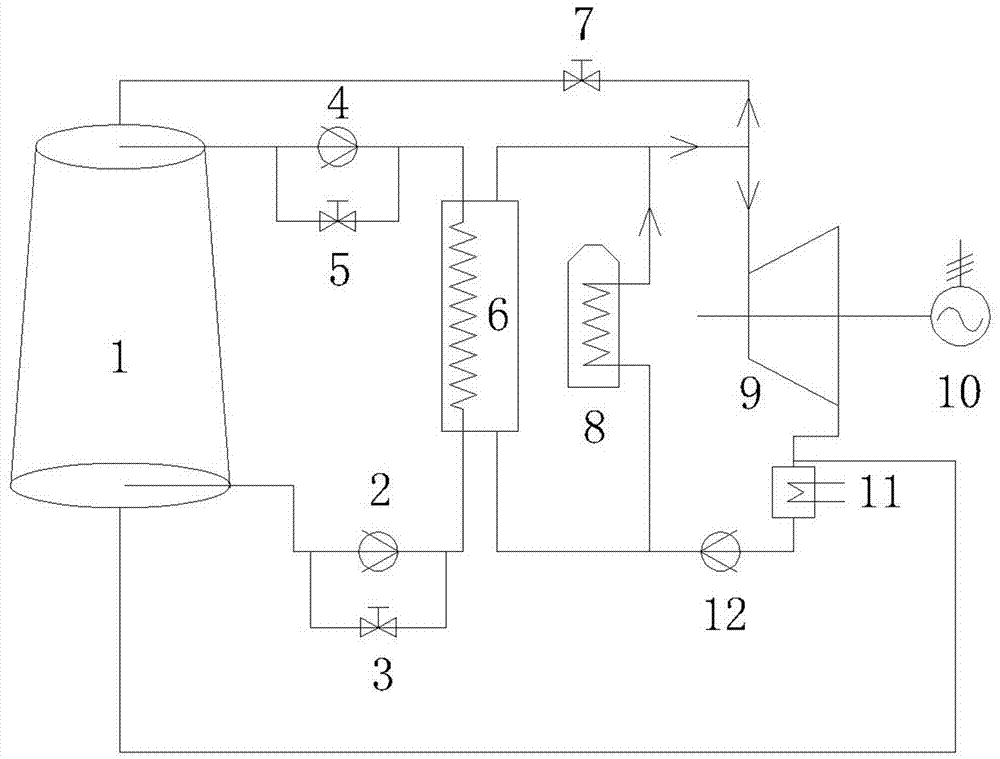

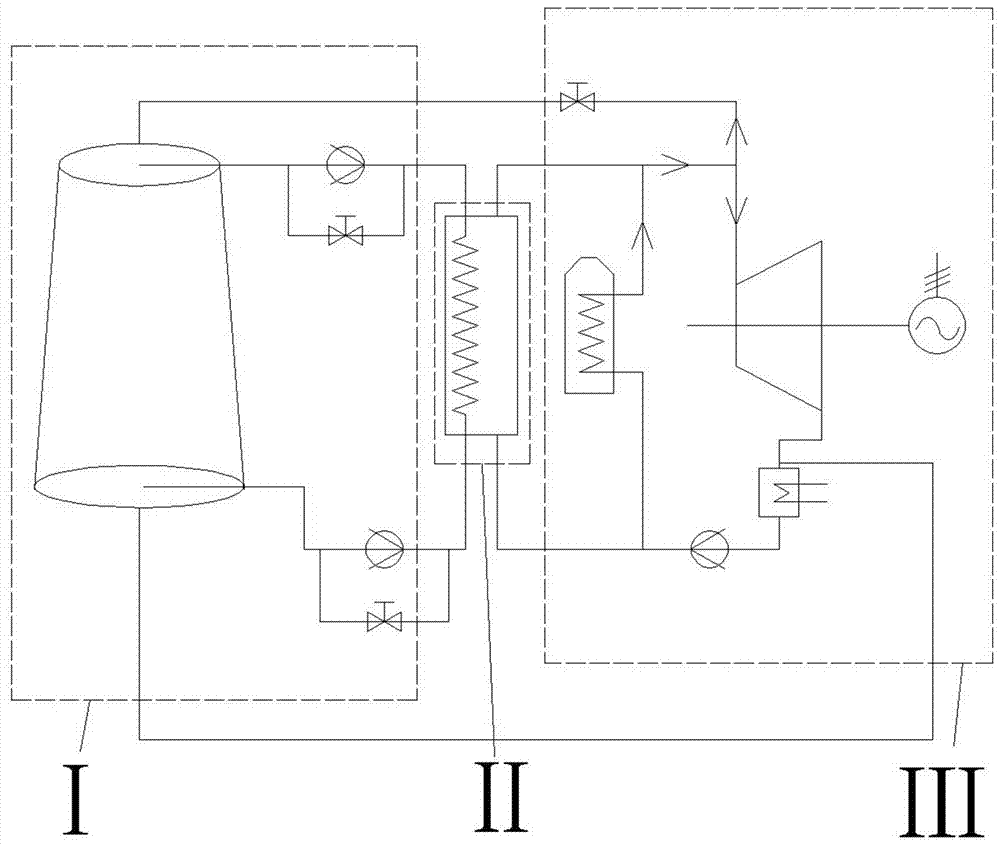

[0032] This embodiment provides a device for peak shaving of a power station using molten salt heat storage, including a molten salt heat storage and release system I, a steam generation system II, and a traditional power generation system III. The molten salt heat storage and release system I is connected to the steam generation system II, the steam generation system II is connected to the traditional power generation system III, and the molten salt heat storage and release system I is connected to the traditional power generation system III.

[0033] The molten salt heat storage and release system I includes a molten salt tank 1, a molten salt heat storage p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com