Laser-electric arc composite welding gas-shielded method for laser front-loading

A hybrid welding and gas shielding technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of oxidation, conversion to blue or even black, and achieve simple implementation process, avoid welding seam oxidation, and use effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

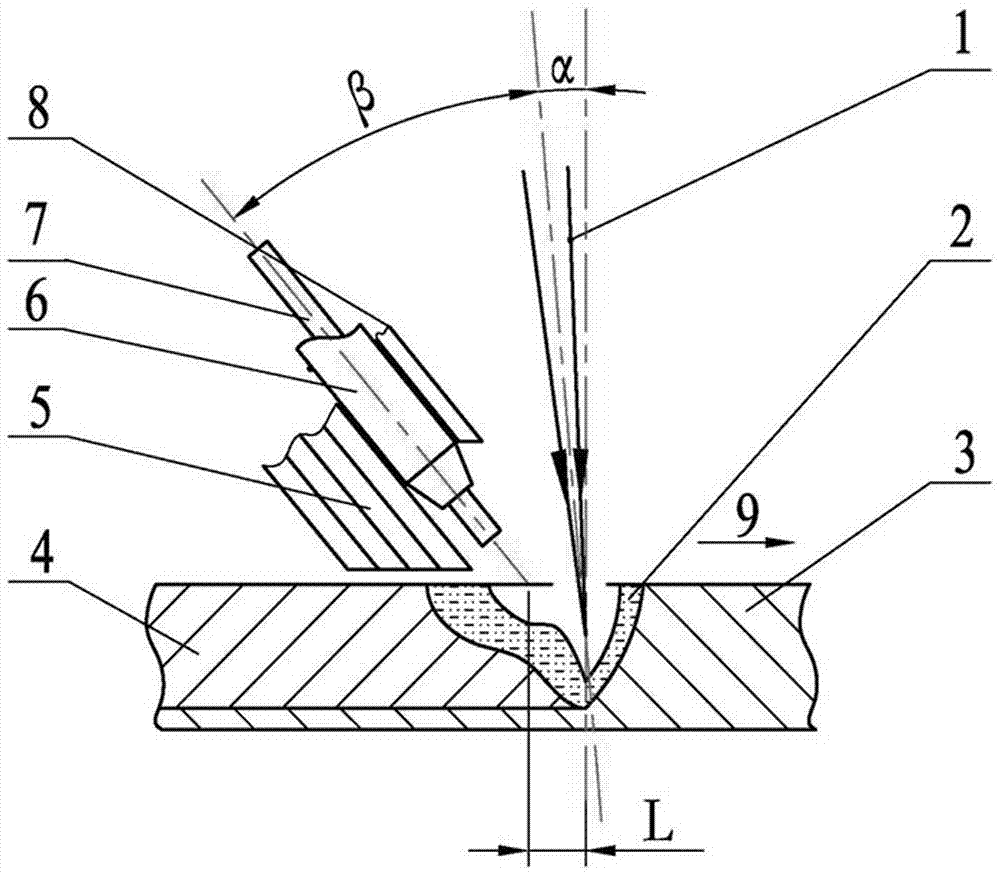

Method used

Image

Examples

Embodiment 1

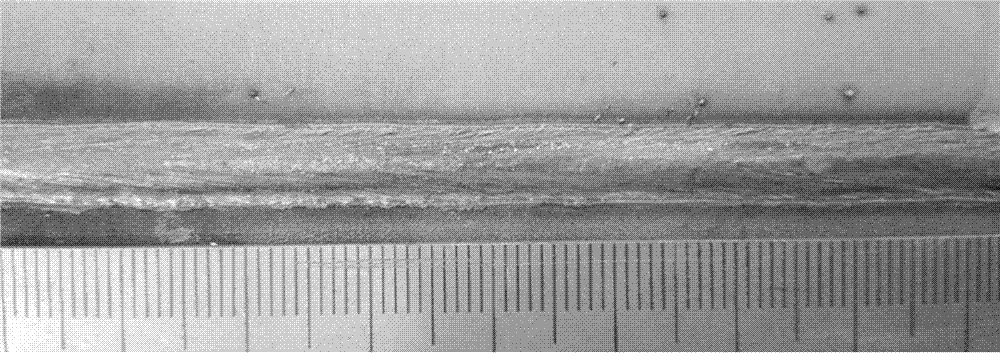

[0021] The welding seam is formed under the protection of ordinary gas, specifically: 5mm thick 304 stainless steel is used as the base material, the welding wire is 308L with a diameter of 1.2mm; the disc laser output 4.5KW laser and MAG composite welding, only rely on the output of the arc welding torch Protective gas (98%Ar+2%CO 2 ) for protection, the gas flow rate is 12L / min, the welding speed is 1.8m / min, the defocus amount is -2mm, and the distance between the light wires is 1mm. Welding effect such as figure 2 As shown, the surface of the weld seam presents a black oxidation phenomenon.

Embodiment 2

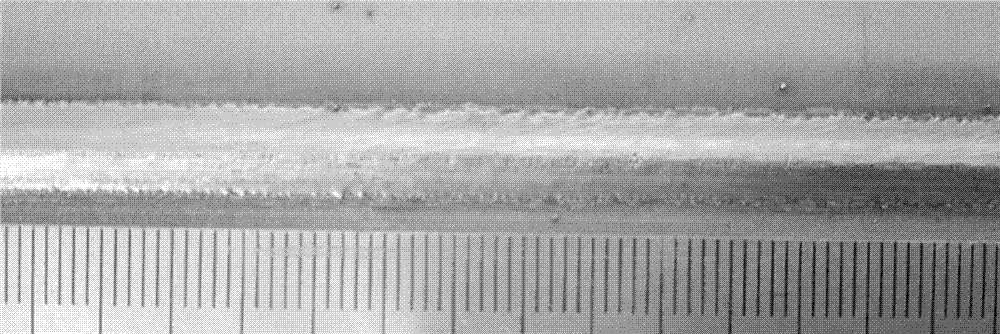

[0023] The welding seam is formed under the gas protection of the present invention, specifically: 304 stainless steel with a thickness of 5mm is used as the base material, and the welding wire is 308L with a diameter of 1.2mm; the disc laser outputs 4.5KW laser and MAG composite welding, and the welding speed is 1.8m / min, defocus amount -2mm, distance between light filaments is 1mm, the shielding gas (98%Ar+2%CO2) output in the arc welding torch 2 ), the gas flow rate is 12L / min, 99.99% Ar is used to protect the area where the laser interacts with the base metal, the gas flow rate is 10L / min, 99.99% Ar is used to protect the formed weld, four gas channels are used, and the gas flow rate is 30L / min min. Welding effect such as image 3 As shown, the surface of the weld seam is golden yellow, which greatly reduces the degree of oxidation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap