Water-based magneto-rheological closed flexible polishing head based on normal force

A flexible polishing and magnetorheological technology, which is applied in the direction of grinding/polishing equipment, grinding heads, grinding machine parts, etc., can solve the problems of low processing efficiency, increasing the size of the polishing device, increasing the cost of the polishing device, etc., to achieve Effect of reducing production cost and reducing device size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

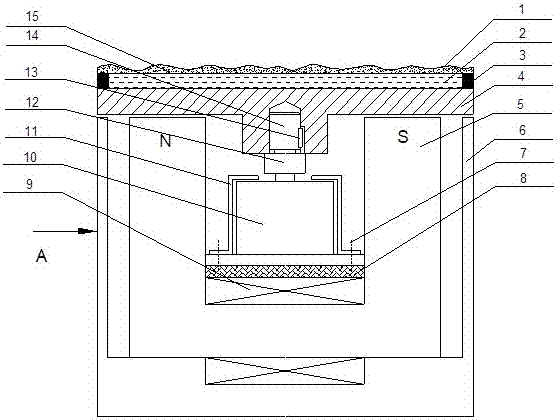

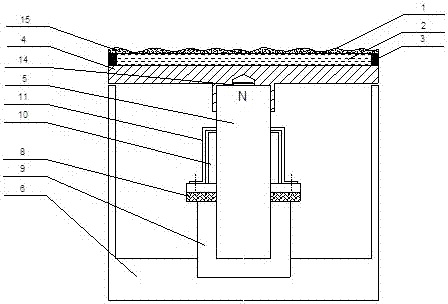

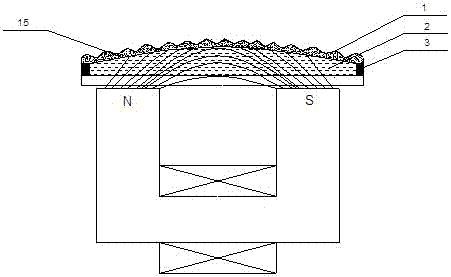

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0011] combine figure 1 and figure 2 , a water-based magnetorheological closed flexible polishing head based on normal force according to the present invention, comprising a flexible grinding disc 1, a magnetorheological fluid 2, a flexible sealing ring 3, a turntable 4, a C-shaped yoke 5, Shell 6, bolt 7, partition 8, electromagnetic coil 9, motor 10, magnetic isolation sleeve 11, coupling 12, key 13, shaft 14 and abrasive grain 15.

[0012] The center of the bottom of the turntable 4 is provided with a rotating shaft, and the rotation axis has a blind hole on the upper side. The flexible abrasive disc 1 is arranged in parallel above the turntable 4, and a flexible sealing ring 3 is arranged between the two, and is fixed by superglue. The flexible abrasive disc 1, The flexible sealing ring 3 and the turntable 4 form a sealed chamber, the magnetorheologica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com