Anode material, preparation method thereof, anode, lithium ion total battery and manufacturing method

A technology of negative electrode material and production method, which is applied in the direction of electrolyte battery manufacturing, negative electrode, battery electrode, etc., can solve the problems of lack of high-performance sodium ion battery positive electrode material, limited practicability, and high use cost, and achieves low price and cycle life. Long and safe performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

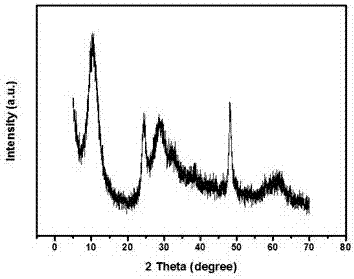

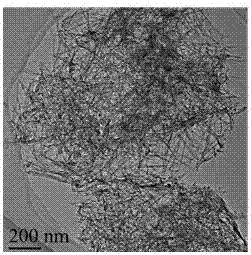

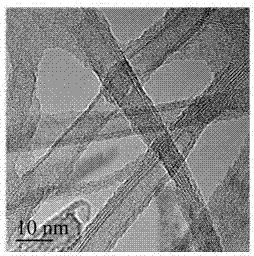

[0043] Synthetic Na 2 Ti 3 o 7 Nanotube material: 0.5g TiO 2 Add the nanopowder to 20mL of 10mol / L NaOH aqueous solution, stir well, and heat the mixed solution at 130°C for 24 hours in a high-pressure reaction kettle. After the reaction, the white precipitate in the lower layer was fully washed with distilled water, dried in air and then annealed at 400° C. for 1 hour.

[0044] Synthetic Na 2 Ti 3 o 7 Common material: Na 2 CO 3 Powder and TiO 2 The nanopowders were mixed at a molar ratio of 1:3, and then ball milled at 300 rpm for 10 hours. Finally the mixture was heated at 700°C for 10 hours.

[0045] Synthetic Li 4 Ti 5 o 12 Material: Will Li 2 CO 3 Powder and TiO 2 Nanopowders are mixed in a molar ratio of 2:5, where Li 2 CO 3 Powder excess 2%, and then ball milled at 300rpm for 10 hours. Finally the mixture was heated at 700°C for 10 hours.

[0046] In order to test Na 2 Ti 3 o 7 The advantages of nanotube materials as lithium ion negative electrode...

Embodiment 2

[0052] Synthetic Na 2 Ti 3 o 7 Nanotube material: 0.5g TiO 2 Add the nanopowder to 20mL of 10mol / L NaOH aqueous solution, stir well, and heat the mixed solution at 130°C for 24 hours in a high-pressure reaction kettle. After the reaction, the white precipitate in the lower layer was fully washed with distilled water, dried in air and then annealed at 400° C. for 1 hour.

[0053] Synthesis of LiMn 2 o 4 Material: First, mix 0.1mol Na with stirring 2 CO 3 Add 1L 0.1mol / L MnSO 4 In aqueous solution, stirred for 10 hours, MnCO was obtained by washing and precipitation 3 Microspheres, dried in an oven. Finally, the MnCO was calcined at 700 °C 3 and Li 2 CO 3 (2% excess) 4:1 mole ratio mixture for 10 hours.

[0054] Preparation of negative electrode: Na 2 Ti 3 o 7 Nanotube material, conductive carbon black, and polyvinylidene fluoride are mixed evenly at a mass ratio of 80:15:5, adjusted into a slurry in N-methylpyrrolidone solution, evenly coated on Cu foil or Al fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com