Deodorized instant canned rana japonica oil and preparation method thereof

A technology of forest frog oil and deodorization, which is applied in the field of food processing, can solve the problems of changing the functional disadvantage, not having the convenience of eating, and cannot be compounded with forest frog oil, etc., and achieves good taste, improved survivability, and anti-fatigue functions. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

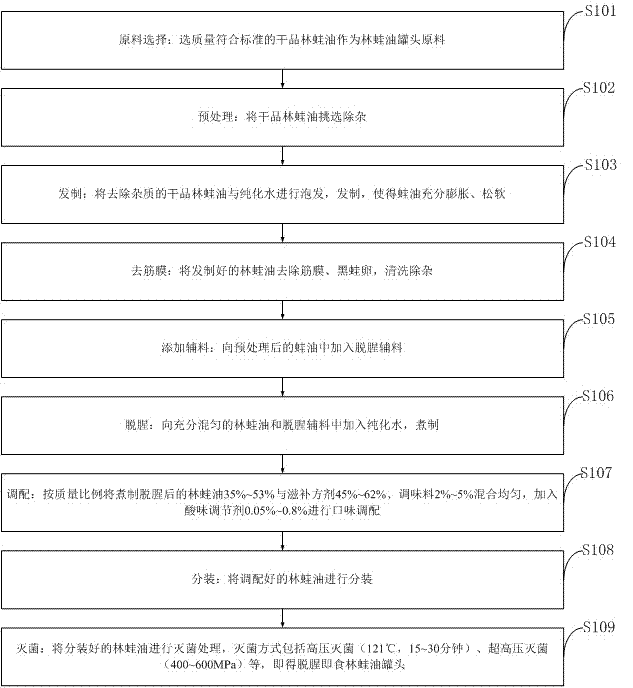

[0037] Such as figure 1 As shown, the preparation method of the deodorized instant Rana oil canned provided by the embodiment of the present invention comprises the following steps:

[0038] S101: Raw material selection: select the dried wood frog oil whose quality meets the standard as the raw material for canned wood frog oil;

[0039] S102: Pretreatment: selecting and removing impurities from the dried wood frog oil;

[0040] S103: hair processing: soaking the dried wood frog oil from which impurities have been removed and purified water, and hair processing, so that the frog oil is fully expanded and soft;

[0041] S104: remove fascia: remove fascia and black frog eggs from the processed wood frog oil, wash and remove impurities;

[0042] S105: Add auxiliary materials: add deodorizing auxiliary materials to the pretreated frog oil;

[0043] S106: deodorization: add purified water to the well-mixed wood frog oil and deodorization auxiliary materials, and cook;

[0044] ...

Embodiment 1

[0053] The preparation of deodorizing instant Rana oil canned with anti-fatigue function:

[0054] Raw material selection: select the yellow or light yellow block translucent dry wood frog oil that meets the standard as the raw material for canned wood frog oil;

[0055] Pretreatment: select the dried Rana oil to remove impurities;

[0056] Hair making: Soak 50g of the dried wood frog oil that has been removed of impurities and purified water at a ratio of 1:80, and the hair making time is 10 hours, so that the frog oil is fully expanded and soft;

[0057] Fascia removal: Remove the fascia and black frog eggs from the processed wood frog oil, and wash and remove impurities;

[0058] Add auxiliary materials: Add 20g of deodorizing auxiliary materials to the pretreated frog oil. The auxiliary material package used contains 6g of tangerine peel, 10g of cooking wine, 3g of ginger slices, and 1g of Huoxiang;

[0059]Deodorization: Add purified water to the well-mixed wood frog oi...

Embodiment 2

[0064] The preparation of deodorizing instant Rana oil canned with anti-fatigue function:

[0065] Raw material selection: select the yellow or light yellow block translucent dry wood frog oil that meets the standard as the raw material for canned wood frog oil;

[0066] Pretreatment: select the dried Rana oil to remove impurities;

[0067] Hair-making: Soak 50g of the dried wood frog oil that has been removed of impurities and purified water at a ratio of 1:100, and the hair-making time is 12 hours, so that the frog oil is fully expanded and soft;

[0068] Fascia removal: Remove the fascia and black frog eggs from the processed wood frog oil, and wash and remove impurities;

[0069] Add auxiliary materials: Add 10g of deodorizing auxiliary materials to the pretreated frog oil, and the auxiliary materials used include 3g of bay leaves, 4g of licorice, and 3g of star anise;

[0070] Deodorization: Add purified water to the well-mixed wood frog oil and deodorization auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com