Aquaculture wastewater treatment system and method

A breeding wastewater and treatment system technology, applied in animal husbandry wastewater treatment, multi-stage water treatment, biological water/sewage treatment, etc., can solve problems such as difficult to meet treatment requirements, and achieve the effect of COD removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

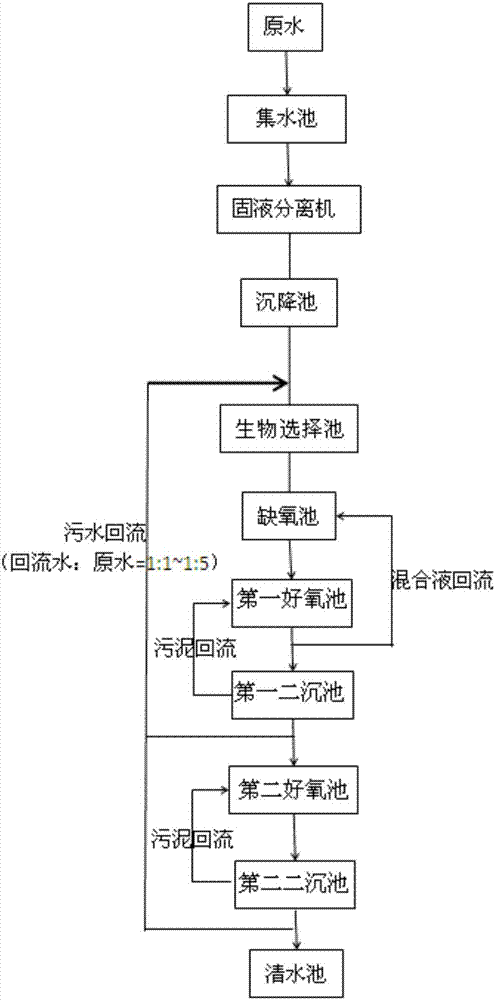

[0031] Refer to attached figure 1 As shown, the aquaculture wastewater treatment system of this embodiment includes a sump, a solid-liquid separator, a settling tank, a biological selection tank, an anoxic tank, a first aerobic tank, a first second settling tank, and a second aerobic tank connected in sequence. pond, second secondary sedimentation pond and clear water pond.

[0032] Wherein, the outlet of the first aerobic tank is also provided with a first return pipe for returning the mixed solution to the anoxic tank. The outlet of the first secondary sedimentation tank is also provided with a second return pipe for returning sludge to the first aerobic tank; the outlet of the second secondary sedimentation tank is also provided with a second return pipe for returning sludge to the second aerobic tank The third return pipeline; the outlet of the first secondary sedimentation tank is also provided with a fourth return pipeline for returning sewage to the biological selectio...

Embodiment 2

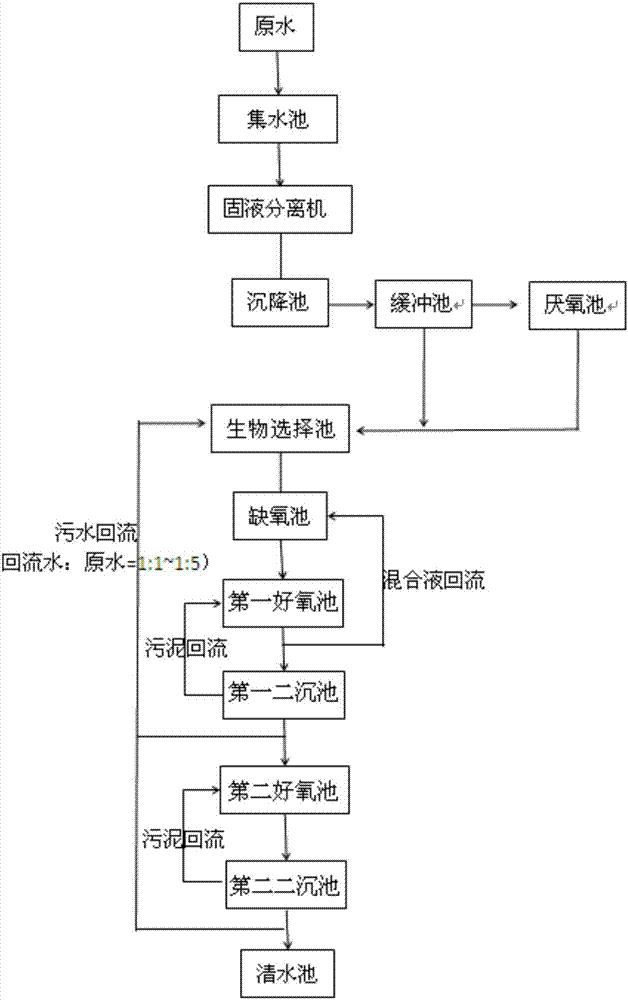

[0044] Refer to attached figure 2 As shown, the difference between the second embodiment and the first embodiment is that a buffer tank and an anaerobic tank are sequentially arranged between the sedimentation tank and the biological selection tank. Correspondingly, when treating sewage, the raw water after sedimentation treatment from the sedimentation tank first enters the buffer tank, and then pumps from the buffer tank into the anaerobic tank, and stays in the anaerobic tank for 1 ~5 days, after the reaction occurs, enter the biological selection pool. The remaining parts are the same as those in the first embodiment above, and will not be repeated here.

[0045] The present invention can thoroughly solve the problem that ammonia nitrogen in the aquaculture sewage is difficult to effectively remove by adopting the above two aquaculture wastewater treatment systems and corresponding treatment methods, and can also effectively remove COD at the same time, and the water ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com