Water treatment method for hilly country rural area micro-pollution water sources

A treatment method and micro-pollution technology, which is applied in the field of water treatment, can solve the problems of not reaching the treatment effect, and achieve the effect of simple structure, low manufacturing cost and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

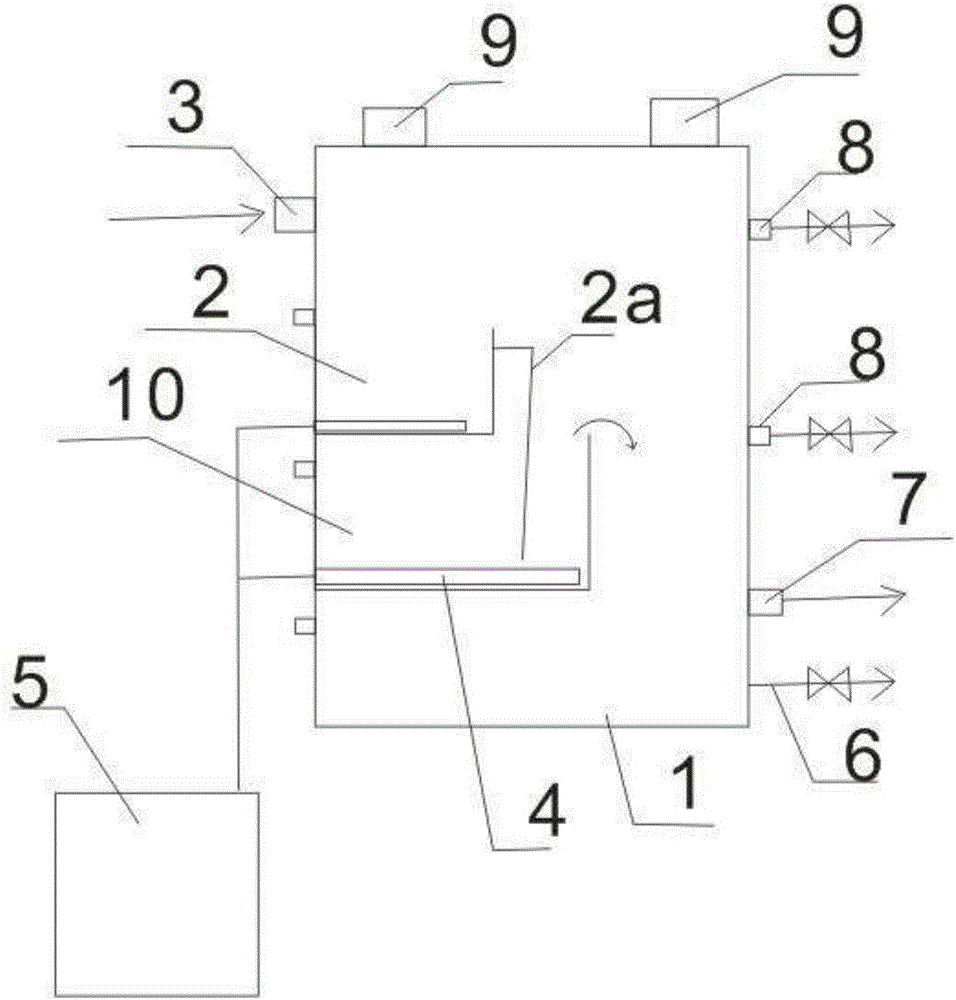

[0015] Example 1, such as figure 1 As shown: the integrated biochemical drinking water treatment device of the present invention consists of a sedimentation tank 1, an oxidation pretreatment tank 2, a source water inlet 3, an aeration pipe 4, a blower 5, a sewage pipe 6, a water outlet 7, and an overflow port 8 , Inspection port 9, Yu flocculation sedimentation tank 10 etc. composition. The sedimentation tank 1 is a box, and the oxidation pretreatment tank 2 and the flocculation sedimentation tank 10 are built from top to bottom against the same side wall in the sedimentation tank 1. The width of the oxidation pretreatment tank 2 is smaller than the width of the flocculation sedimentation tank 10, and the flocculation and sedimentation The width of the pool 10 is smaller than that of the sedimentation tank 1, and the width should be satisfied as far as possible: when overflowing from the flocculation sedimentation tank, it overflows to the middle of the sedimentation tank 1. ...

Embodiment 2

[0016] Embodiment 2: Prepare four integrated biochemical drinking water treatment devices and drop in potassium permanganate respectively in the oxidation pretreatment tank 2, and the input amounts of potassium permanganate in the four integrated biochemical drinking water treatment devices are respectively 1g / L source water, 1.2g / L source water, 1.4g / source water, 1.6g / L source water, flocculants are put into the flocculation sedimentation tank 10, and the flocculants put into the four integrated biochemical drinking water treatment devices are respectively It is ferric oxide, basic alumina, ferrous sulfate, and polyalumina, and the dosage is 0.4g / L. There is activated carbon suction in the sedimentation tank 1, and the activated carbon in the four integrated biochemical drinking water treatment devices The dosage is 1.2g / L source water, 1.4g / L source water, 1.6g / L source water, 1.8g / L source water respectively, and the agent can be added from the respective agent filling port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com