Stone-like multicolor paint and production technology thereof

A production process and multi-color paint technology, applied in the field of imitation stone multi-color paint, can solve problems such as poor heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

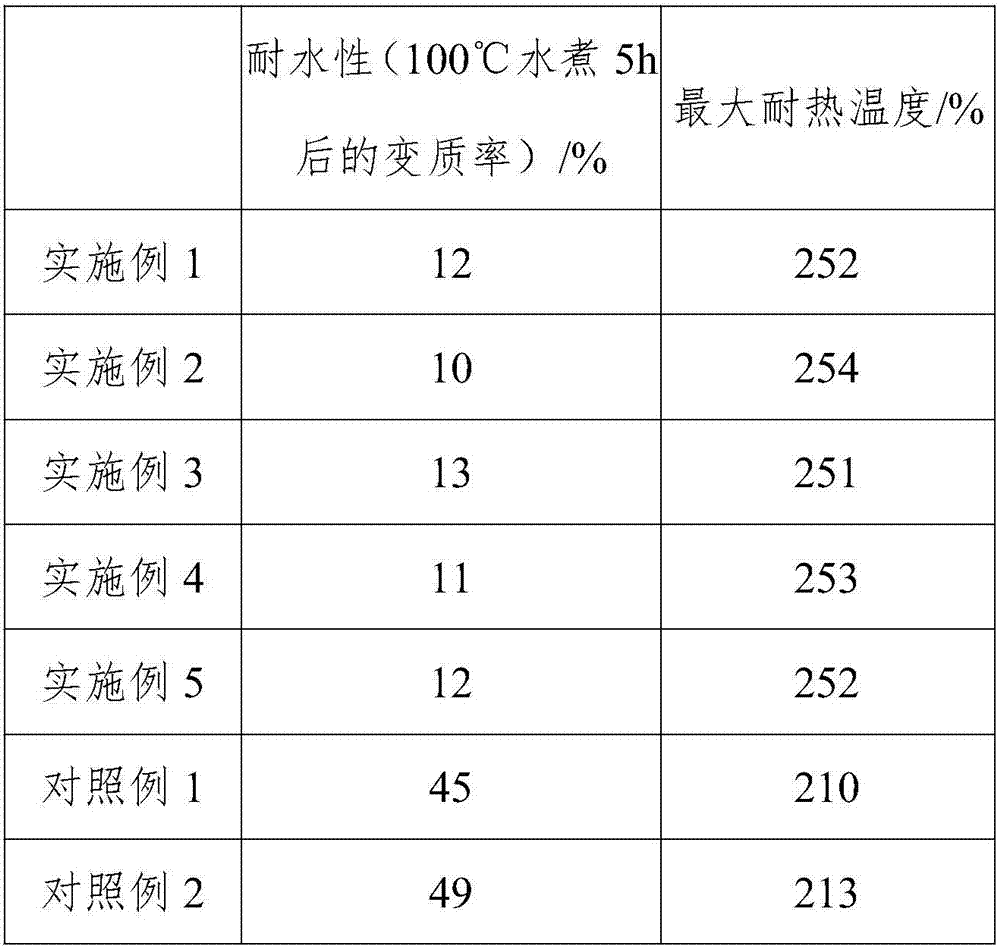

Examples

Embodiment 1

[0021] A stone-like colorful paint, made of the following raw materials in parts by weight: 4 parts of 2,6-naphthalene dicarboxylic acid, 3 parts of terephthalic acid, 2 parts of butanediol, 4 parts of octadecyltrimethylammonium, 1 part of montmorillonite powder, 15 parts of acrylic emulsion, 10 parts of urushiol epoxy resin, 2 parts of nano titanium dioxide, 3 parts of sodium lauryl sulfate, 3 parts of colorful rock powder, 2 parts of thickener, 1 part of defoamer share.

[0022] A kind of imitation stone colorful paint and its production process, its production process comprises the following several steps:

[0023] (1) Butanediol, terephthalic acid and 2,6-naphthalene dicarboxylic acid are put into the reaction kettle, under N 2 Under a protective atmosphere, adjust the temperature of the reactor to 240°C, react for a period of time, take a small amount of the reaction solution to measure the acidity value, when the acidity value is 9mgKOH / g, add an appropriate amount of h...

Embodiment 2

[0028] A stone-like colorful paint, made of the following raw materials in parts by weight: 15 parts of 2,6-naphthalene dicarboxylic acid, 12 parts of terephthalic acid, 7 parts of butanediol, 9 parts of octadecyltrimethylammonium, 8 parts of montmorillonite powder, 25 parts of acrylic emulsion, 25 parts of urushiol epoxy resin, 7 parts of nano titanium dioxide, 7 parts of sodium lauryl sulfate, 8 parts of colorful rock powder, 6 parts of thickener, 3 parts of defoamer share.

[0029] A stone-like colorful paint, the production process of which comprises the following steps:

[0030] (1) Butanediol, terephthalic acid and 2,6-naphthalene dicarboxylic acid are put into the reaction kettle, under N 2 Under a protective atmosphere, adjust the temperature of the reactor to 240°C, react for a period of time, take a small amount of the reaction solution to measure the acidity value, when the acidity value is 12mgKOH / g, add an appropriate amount of hydrochloric acid for acidolysis, w...

Embodiment 3

[0035] A stone-like colorful paint, made of the following raw materials in parts by weight: 7 parts of 2,6-naphthalene dicarboxylic acid, 5 parts of terephthalic acid, 3 parts of butanediol, 6 parts of octadecyltrimethylammonium, 3 parts of montmorillonite powder, 18 parts of acrylic emulsion, 15 parts of urushiol epoxy resin, 3 parts of nano titanium dioxide, 2 parts of sodium lauryl sulfate, 5 parts of colorful rock powder, 3 parts of thickener, 1 part of defoamer share.

[0036] A stone-like colorful paint, the production process of which comprises the following steps:

[0037] (1) Butanediol, terephthalic acid and 2,6-naphthalene dicarboxylic acid are put into the reaction kettle, under N 2 Under a protective atmosphere, adjust the temperature of the reactor to 240°C, react for a period of time, take a small amount of the reaction solution to measure the acidity value, when the acidity value is 10mgKOH / g, add an appropriate amount of hydrochloric acid for acidolysis, when...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com