Gas circulating crop straw cracker

A technology for crop straw and gas circulation, applied in the field of agricultural machinery, can solve the problems of anoxic environment that cannot guarantee cracking, low biochar yield, etc., and achieve the effect of improving energy utilization rate and reducing harmful gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

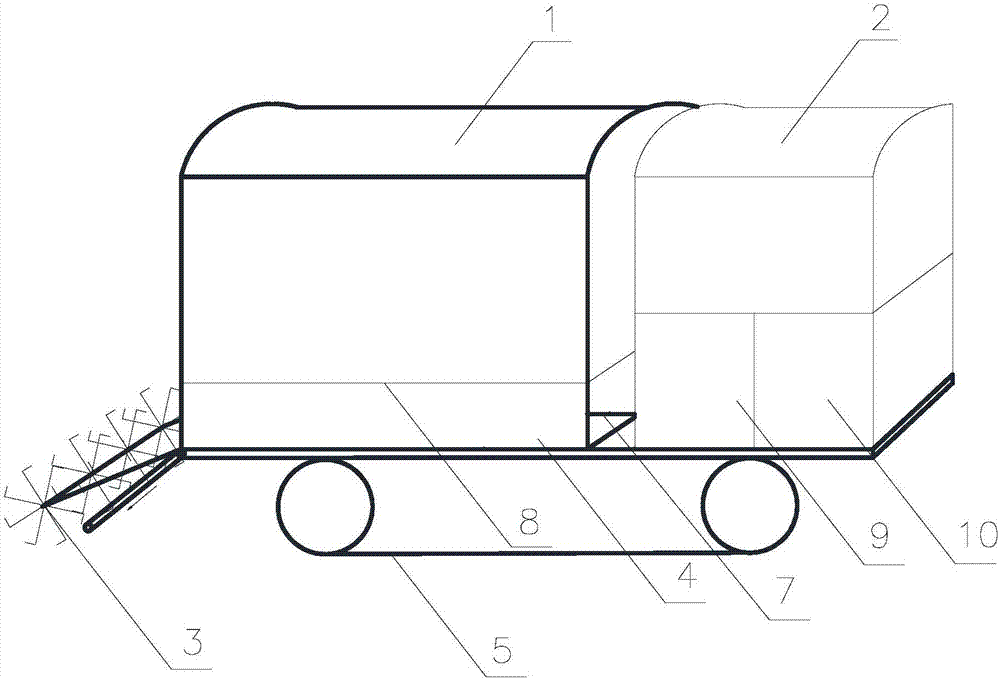

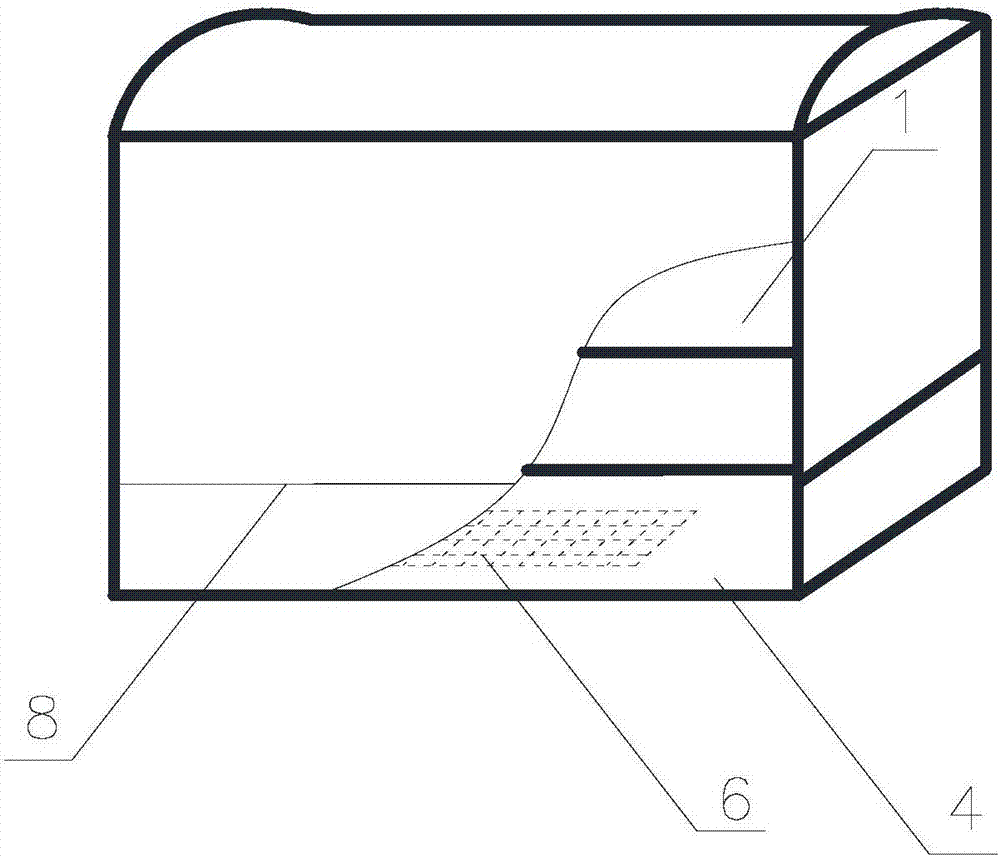

[0032] like figure 1 As shown, a gas circulation crop straw cracker includes four main functional systems: straw collection system, cab, gas separation and circulation system, and biochar cracking and spreading system.

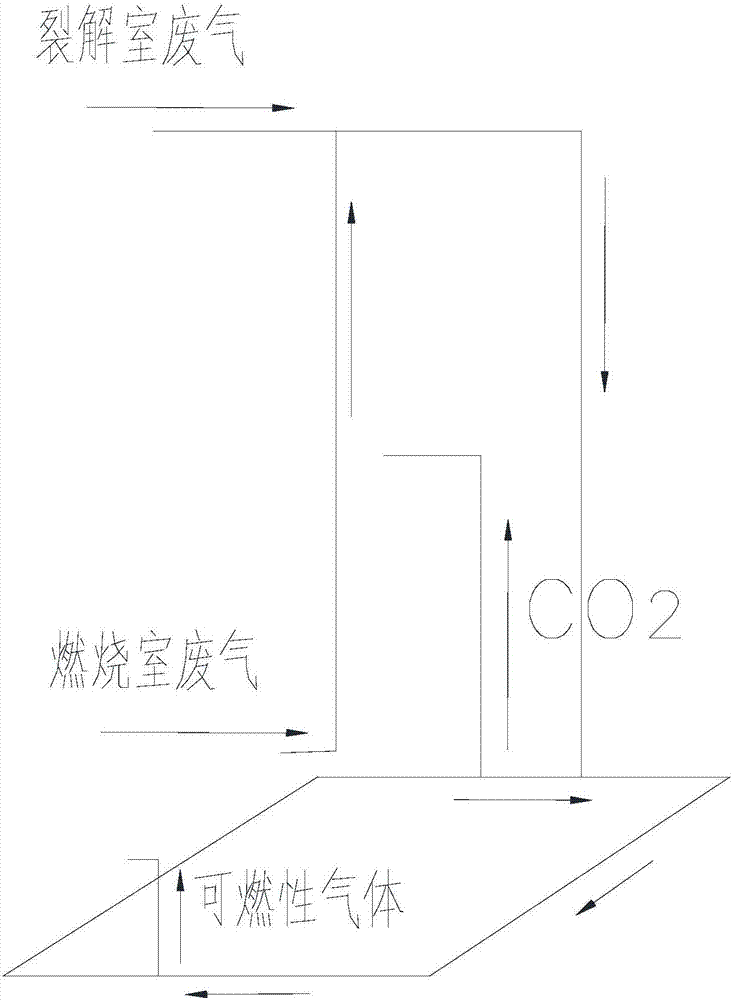

[0033]The driver's cab 2 is used for the driver to drive and control the movement and braking of the body. The straw collection system is used to collect and transport the straw on the surface to the cracking chamber 1 and the combustion chamber 4 . The gas separation circulation system is used to separate and recycle the gas produced in the cracking chamber 1 and the combustion chamber 4 . The biochar cracking and spreading system is used to crack the straw and return the cracked or burned biochar to the farmland.

[0034] The specific implementation of each subsystem will be described in detail below.

[0035] The bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com