Device for extracting zinc by electrodeposition with double electrolytic baths and application of device

A double electrolytic tank, electrowinning technology, applied in the direction of electrolysis process, electrolysis components, electrodes, etc., can solve the problem that it is difficult to avoid the generation of acid mist, and achieve the effect of solving the problem of acid mist, low concentration of sulfuric acid, and reducing remelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

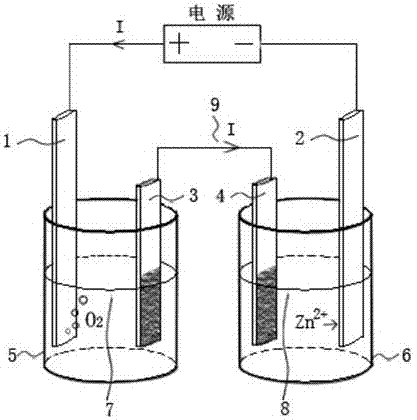

[0031] The device for electrowinning zinc with double electrolytic cells includes an inert anode 1, a pure aluminum cathode 2, an auxiliary electrode I3, an auxiliary electrode II4, an anode tank 5, a cathode tank 6, a sulfuric acid-containing electrolyte solution 7 and a zinc sulfate-containing electrolyte solution 8, An inert anode 1 and an electrolyte 7 containing sulfuric acid are housed in the anode tank 5, an aluminum cathode 2 and an electrolyte 8 containing zinc sulfate are housed in the cathode tank 6, the inert anode 1 is connected to the positive pole of the power supply, and the pure aluminum cathode 2 is connected to the negative pole of the power supply. An auxiliary electrode I3 and an auxiliary electrode II4 are respectively provided in the anode tank 5 and the cathode tank 6 , and the auxiliary electrode I3 and the auxiliary electrode II4 are connected by a wire 9 .

[0032] (1) Preparation of auxiliary electrodes

[0033] Take 5g of lead powder (200 mesh, 3N)...

Embodiment 2

[0040] The device for electrowinning zinc with double electrolytic cells includes an inert anode 1, a pure aluminum cathode 2, an auxiliary electrode I3, an auxiliary electrode II4, an anode tank 5, a cathode tank 6, a sulfuric acid-containing electrolyte solution 7 and a zinc sulfate-containing electrolyte solution 8, An inert anode 1 and an electrolyte 7 containing sulfuric acid are housed in the anode tank 5, an aluminum cathode 2 and an electrolyte 8 containing zinc sulfate are housed in the cathode tank 6, the inert anode 1 is connected to the positive pole of the power supply, and the pure aluminum cathode 2 is connected to the negative pole of the power supply. An auxiliary electrode I3 and an auxiliary electrode II4 are respectively provided in the anode tank 5 and the cathode tank 6 , and the auxiliary electrode I3 and the auxiliary electrode II4 are connected by a wire 9 .

[0041] (1) Preparation of auxiliary electrodes

[0042] Take 5g of lead powder (200 mesh, 3N)...

Embodiment 3

[0046] The device for electrowinning zinc with double electrolytic cells includes an inert anode 1, a zinc cathode 2, an auxiliary electrode I3, an auxiliary electrode II4, an anode tank 5, a cathode tank 6, a sulfuric acid-containing electrolyte solution 7 and a zinc sulfate-containing electrolyte solution 8, and the anode Tank 5 is equipped with inert anode 1 and electrolyte 7 containing sulfuric acid, and cathode tank 6 is equipped with zinc cathode 2 and electrolyte 8 containing zinc sulfate. The inert anode 1 is connected to the positive pole of the power supply, and the zinc cathode 2 is connected to the negative pole of the power supply. Auxiliary electrode I3 and auxiliary electrode II4 are also provided in 5 and cathode tank 6 respectively, and auxiliary electrode I3 and auxiliary electrode II4 are connected by wire 9 .

[0047] (1) Preparation of auxiliary electrodes

[0048] Take 5g of spongy metal lead powder (3N), 1.0% of lead mass barium sulfate, 0.5% of lead mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com