Dry film developing technique used for high density circuit of printed circuit board

A printed circuit board and dry film technology, which is applied in printed circuits, printed circuit manufacturing, photosensitive material processing, etc., can solve problems such as the inability to ensure the electrical performance requirements of high-density circuits, the inability of the development process to meet the needs of industrialization, and the easy generation of development burrs. , to achieve the effect of low cost, low price and no pollution in the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Drain the working solution of the dry film developing tank first, rinse it with tap water, and continue to wash it with deionized water for 30 minutes. Prepare 1 liter of potassium carbonate aqueous solution, wherein potassium carbonate is 20 grams. Add 1 liter of potassium carbonate aqueous solution to the dry film developing tank, heat to 28°C, the pH of the potassium carbonate aqueous solution is 10.5, and the specific gravity is 1.02g / cm 3 . Start the circulating filter pump, put the exposed dry film board of the printed circuit to be developed into the potassium carbonate aqueous solution, spray and soak for 1min; then take out the developed printed circuit board, wash it with tap water for 1min; finally dry it with hot air for 0.4min , into the pattern plating process or inner layer etching process.

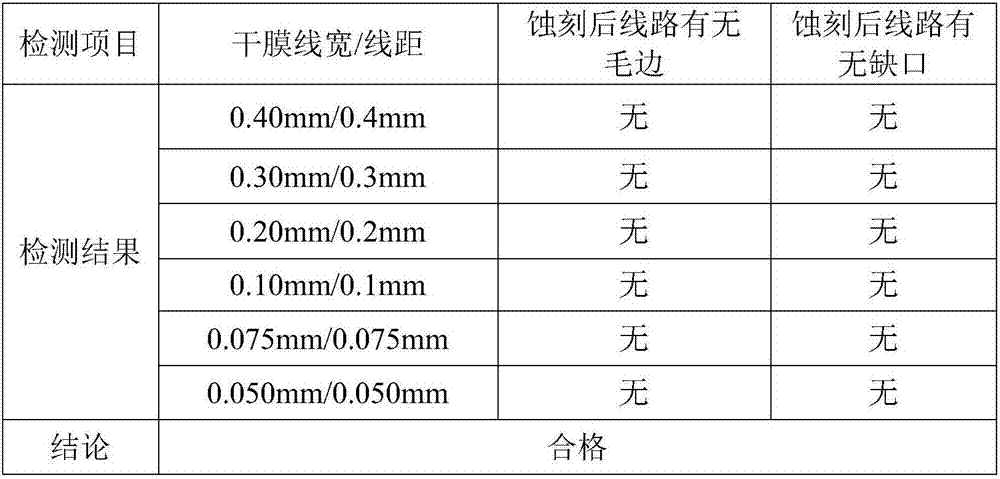

[0015] It can be seen from the experimental results that this process makes the dry film of the high-density circuit flush with the line edge after development, wi...

Embodiment 2

[0019] Drain the working solution of the dry film developing tank first, rinse it with tap water, and continue to wash it with deionized water for 30 minutes. Prepare 1 liter of potassium carbonate aqueous solution, wherein potassium carbonate is 25 grams. Add 1 liter of potassium carbonate aqueous solution to the dry film developing tank, heat to 30°C, the pH of the potassium carbonate aqueous solution is 12, and the specific gravity is 1.03g / cm 3 . Start the circulating filter pump, put the exposed dry film board of the printed circuit to be developed into the potassium carbonate aqueous solution, spray and soak for 1.5min; then take out the developed printed circuit board, wash it with tap water for 1.5min; finally dry it with hot air 0.5min, transfer to pattern electroplating process or inner layer etching process.

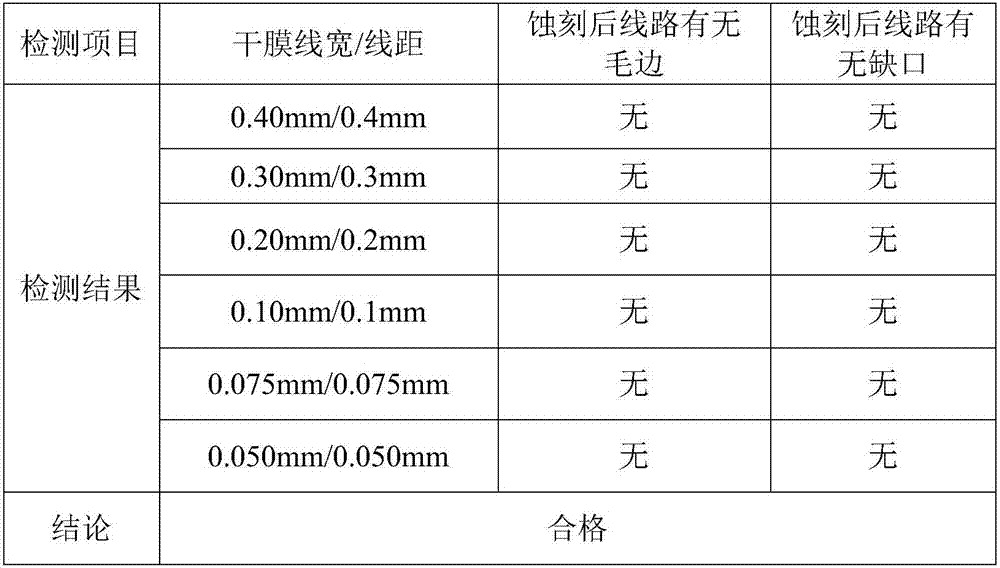

[0020] It can be seen from the experimental results that this process makes the dry film of the high-density circuit flush with the line edge after developm...

Embodiment 3

[0024] Drain the working solution of the dry film developing tank first, rinse it with tap water, and continue to wash it with deionized water for 30 minutes. Prepare 1 liter of potassium carbonate aqueous solution, wherein potassium carbonate is 30 grams. Add 1 liter of potassium carbonate aqueous solution to the dry film developing tank, heat to 32°C, the pH of the potassium carbonate aqueous solution is 13.5, and the specific gravity is 1.05g / cm 3 . Start the circulating filter pump, put the exposed dry film board of the printed circuit to be developed into the dry film developer, spray and soak for 2 minutes; then take out the developed printed circuit board and wash it with tap water for 2 minutes; finally dry it with hot air for 0.6 min, transfer to pattern electroplating process or inner layer etching process.

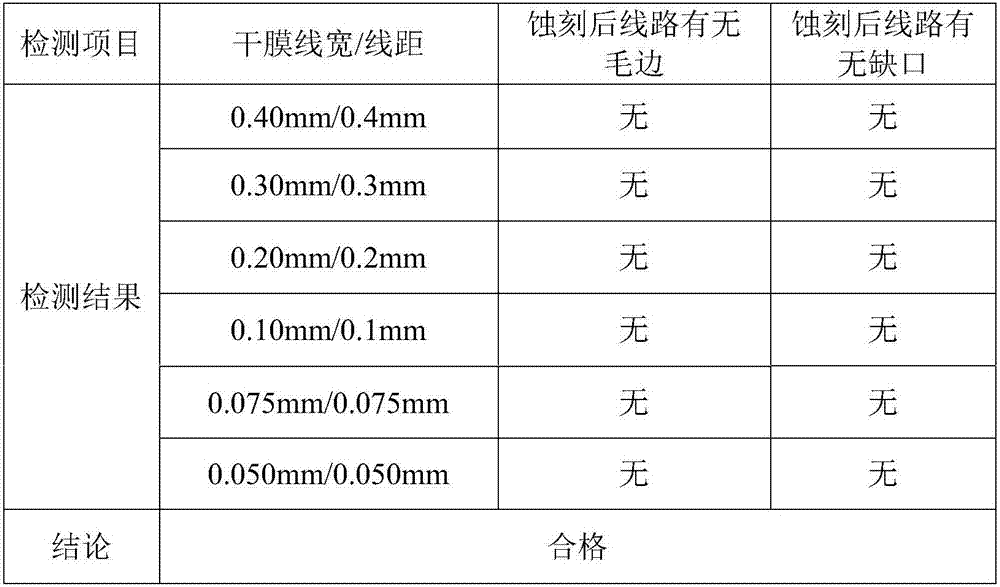

[0025] It can be seen from the experimental results that this process makes the dry film of the high-density circuit flush with the line edge after developmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com