A compound modification method of zeolite and its application in removing phosphate in water

A composite modification and zeolite technology, applied in the field of water treatment, can solve the problems of low exchange capacity and difficult to remove anionic pollutants, and achieve the effect of reducing production cost and improving application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

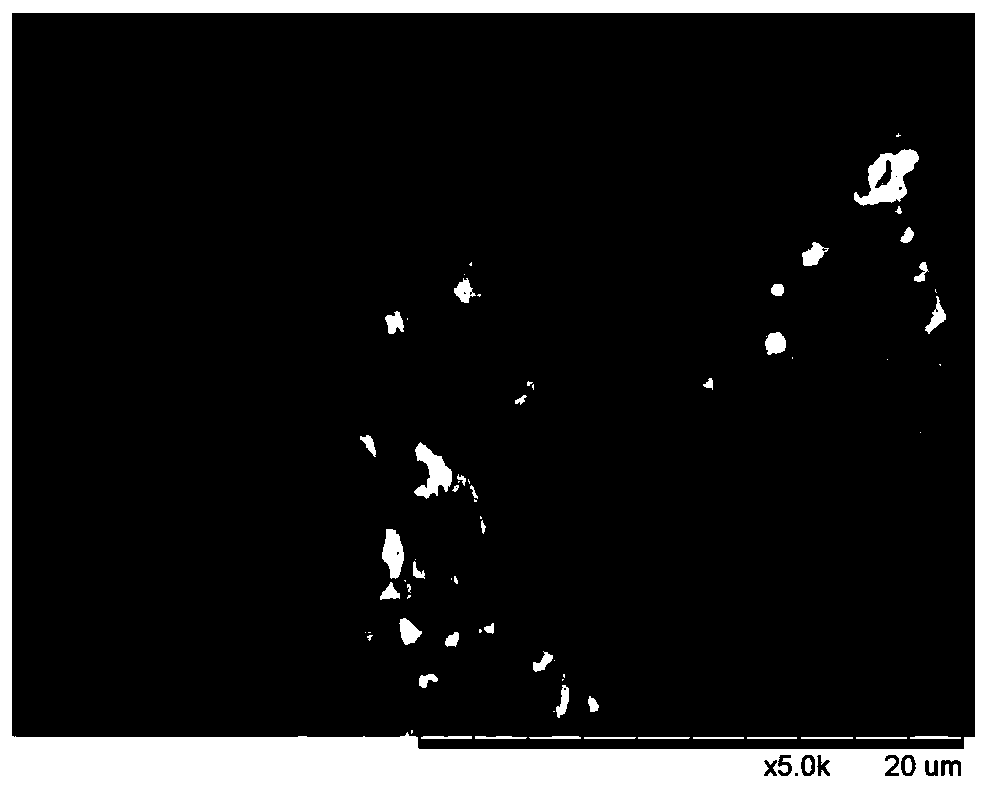

[0020] Preparation of zeolite: 10g of fly ash and 8g of anhydrous sodium carbonate were accurately weighed with an electronic balance, mixed and ground in a mortar for 30 minutes, then placed in a crucible, and calcined in a muffle furnace at 550°C for 2 hours. Add the mixture to 2mol / L sodium hydroxide solution and heat it in a water bath at 80°C for 10h. The product is washed with water until neutral, shaken with 0.01mol / L dilute hydrochloric acid solution for 6h, and then washed repeatedly with deionized water of pH 6.0, then 60°C at low temperature Dry for 24 hours to obtain a synthetic zeolite sample.

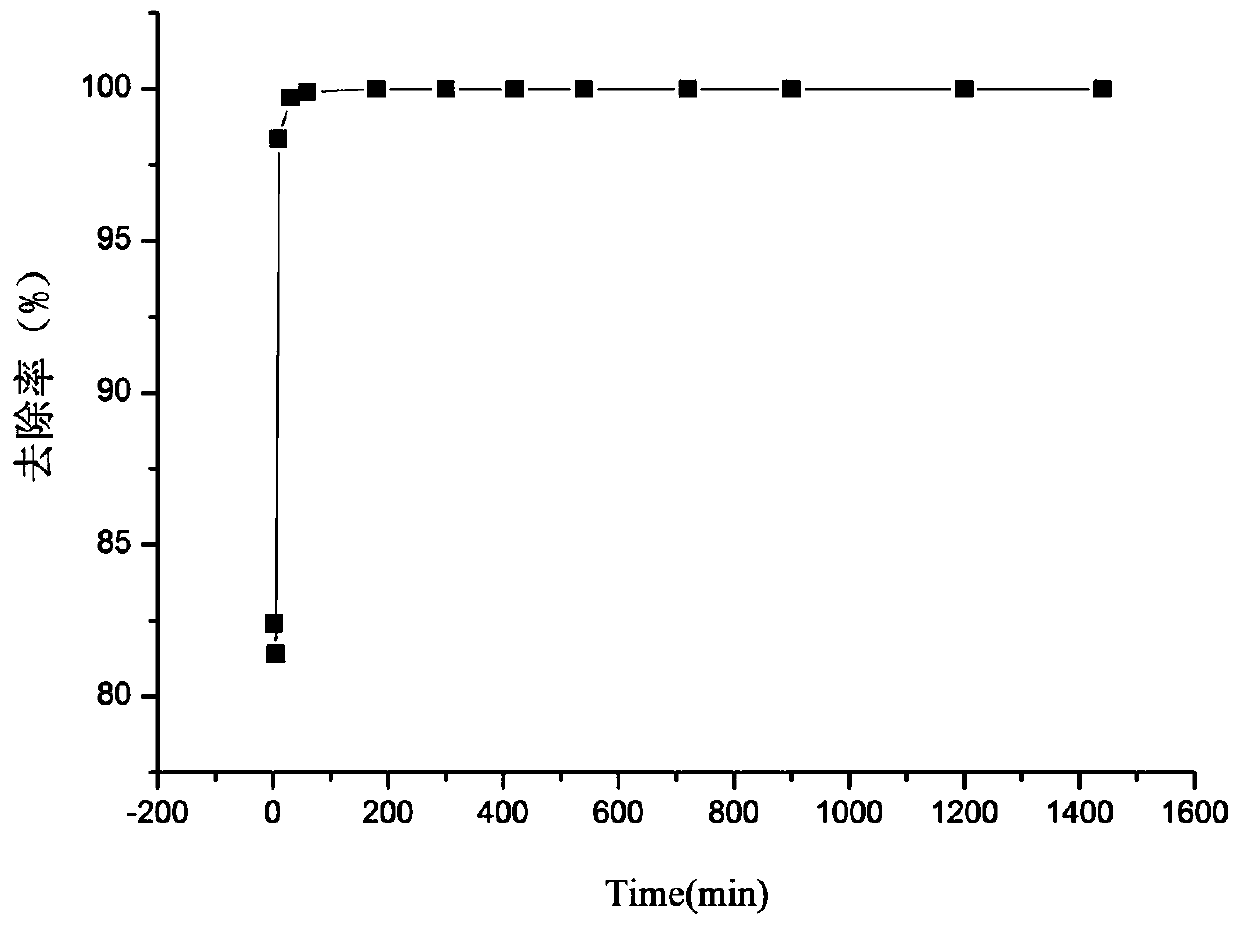

[0021] Take the above 2g of zeolite and add it to 50ml of 0.002mol / L β-cyclodextrin solution, shake it in an air bath for 24 hours, wash it with water, centrifuge, place it in a watch glass, and dry it in a constant temperature drying oven at 50°C for 20 hours to prepare β-cyclodextrin. Cyclodextrin organically modified zeolite; then take 2g of β-cyclodextrin organically m...

Embodiment 2

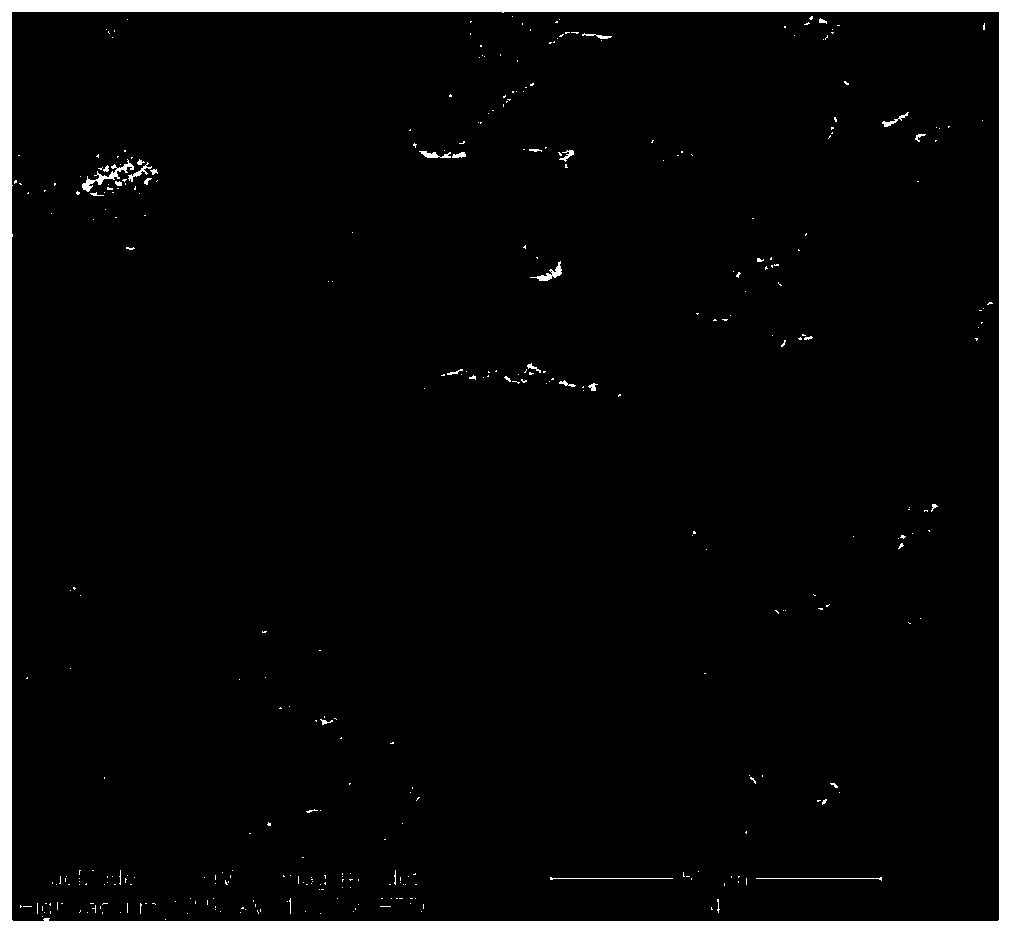

[0024] Preparation of zeolite: Accurately weigh 10g of fly ash and 8g of anhydrous sodium carbonate with an electronic balance, mix them, grind them in a mortar for 30 minutes, place them in a crucible, and calcinate them in a muffle furnace at 600°C for 2 hours. Add the mixture to 2mol / L sodium hydroxide solution and heat it in a water bath at 80°C for 10h. The product is washed with water to neutrality, shaken with 0.01mol / L dilute hydrochloric acid solution for 6h, and then washed repeatedly with deionized water with pH 6.5. Dry for 24 hours to obtain a synthetic zeolite sample.

[0025] Take the above 2g of zeolite and add it to 50ml of 0.01mol / L β-cyclodextrin solution, shake it in an air bath for 24 hours, wash it with water, centrifuge, put it in a watch glass, and dry it in a constant temperature drying oven at 50°C for 20 hours to prepare β-cyclodextrin. Cyclodextrin organically modified zeolite; then take 2g of β-cyclodextrin organically modified zeolite in 50ml of 0...

Embodiment 3

[0028] Preparation of zeolite: 10g of fly ash and 8g of anhydrous sodium carbonate were accurately weighed with an electronic balance, mixed and ground in a mortar for 30 minutes, then placed in a crucible, and calcined in a muffle furnace at 550°C for 2 hours. Add the mixture to 2mol / L sodium hydroxide solution and heat it in a water bath at 85°C for 12h. The product is washed with water to neutrality, shaken with 0.01mol / L dilute hydrochloric acid solution for 6h, and then repeatedly washed with deionized water with pH 6.0. Dry for 28 hours to obtain a synthetic zeolite sample.

[0029] Take the above 2g of zeolite and add it to 50ml of 0.015mol / L β-cyclodextrin solution, shake it in an air bath for 24 hours, wash it with water, centrifuge, put it in a watch glass, and dry it in a constant temperature drying oven at 45°C for 22 hours to prepare β-cyclodextrin. Cyclodextrin organically modified zeolite; then take 2g of β-cyclodextrin organically modified zeolite in 50ml of 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com