Montmorillonite water purifying agent for adsorbing reactive dyes in water body

A technology of reactive dyes and stone water purifiers, applied in the direction of adsorption of water/sewage treatment, water pollutants, water/sewage treatment, etc., can solve the problem of high price, achieve the effect of improving adsorption and increasing the number of positive charges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

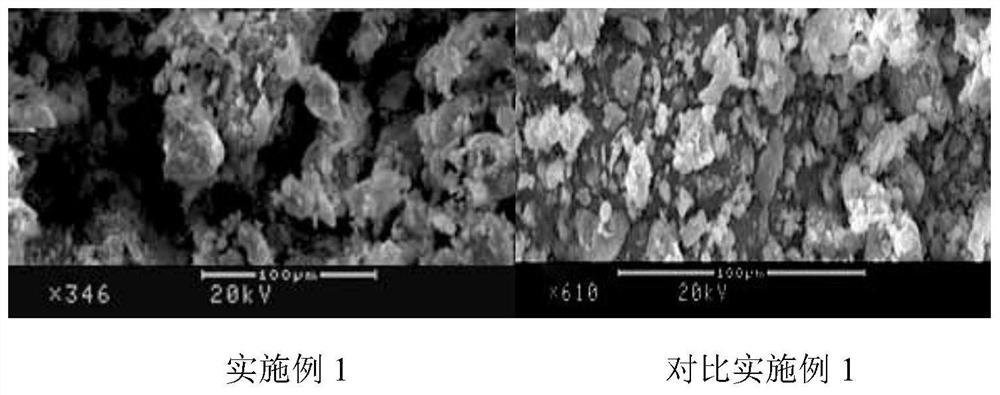

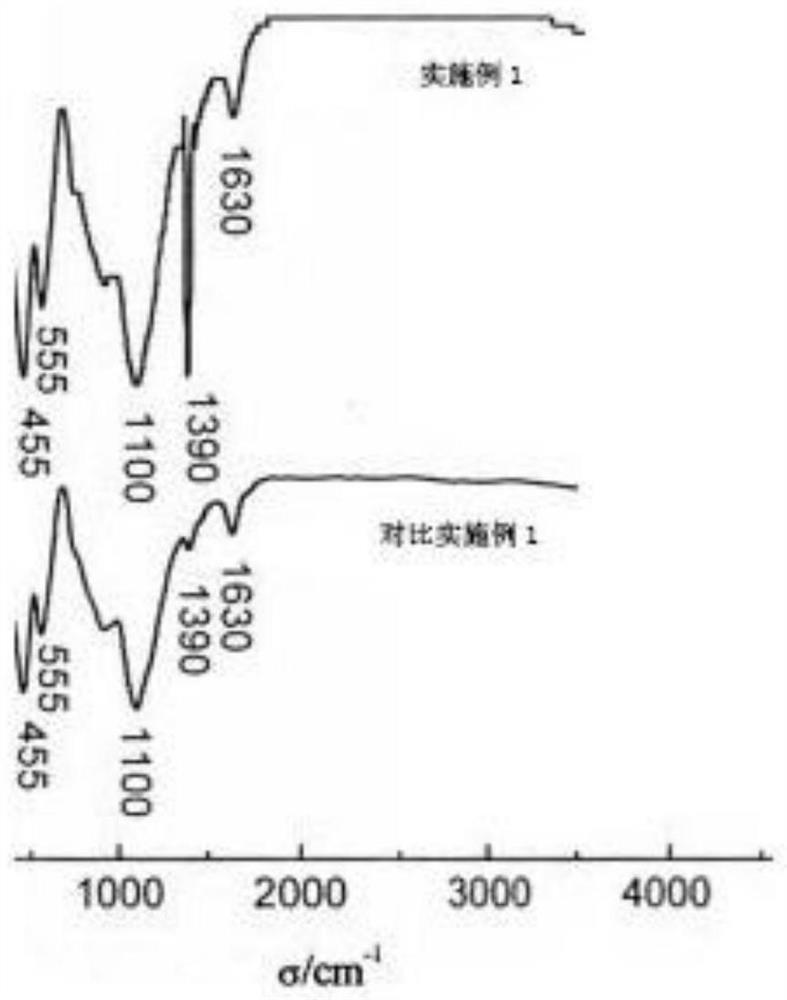

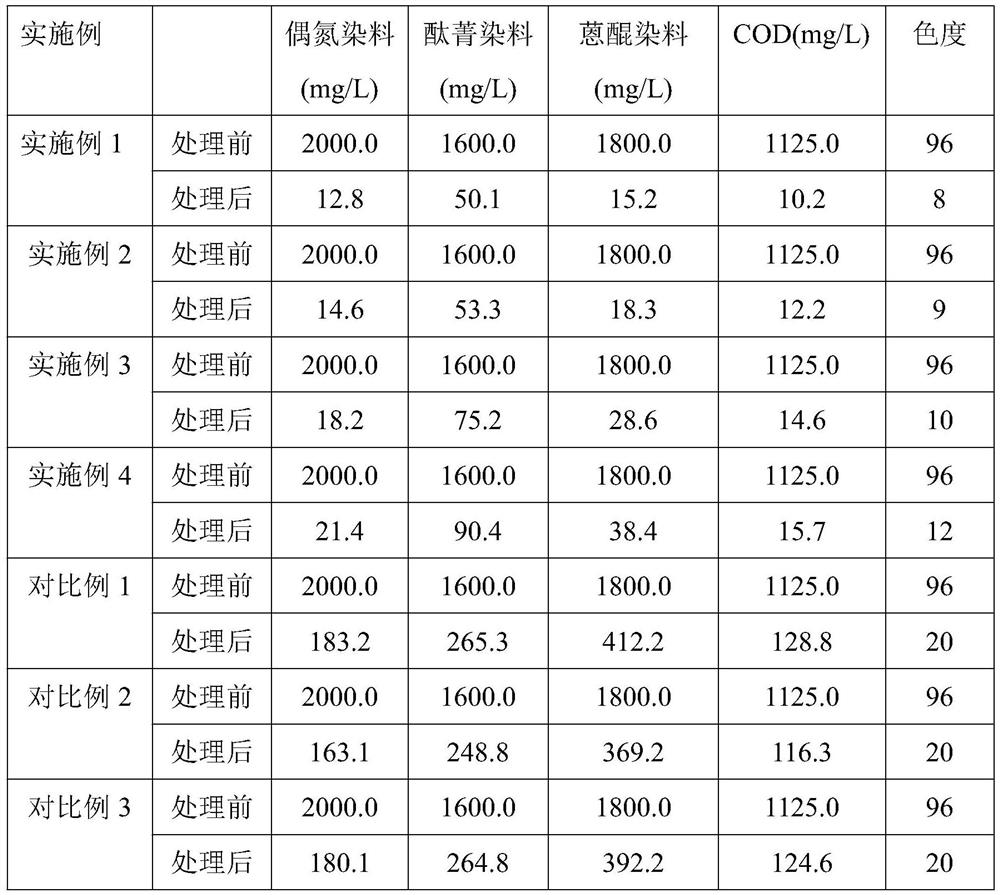

Embodiment 1

[0027] A preparation method of montmorillonite water purifying agent capable of adsorbing reactive dyes in water body, the method includes the following steps:

[0028] 1) Pulping: montmorillonite is added with deionized water to make a slurry, the concentration of the slurry reaches 35wt%, and ultrasonic treatment is performed for 30 minutes to make it uniformly dispersed in water.

[0029] 2) Pre-activation: the montmorillonite slurry after ultrasonic treatment is pre-activated with cation exchange resin to obtain pre-activated montmorillonite.

[0030] 3) Load: prepare a slurry of pre-activated montmorillonite and deionized water in a ratio of 1:8, add a mixed solution of 0.06mol / L cerium nitrate solution and 0.03mol / L ferric nitrate solution, and heat to 90 Stir for 6 hours at °C.

[0031] 4) Centrifuging, roasting in a muffle furnace at 400°C for 1.5 hours, cooling and grinding to obtain the montmorillonite water purifying agent.

Embodiment 2

[0033] A preparation method of montmorillonite water purifying agent capable of adsorbing reactive dyes in water body, the method includes the following steps:

[0034] 1) Pulping: montmorillonite is added with deionized water to make a slurry, the slurry concentration reaches 30wt%, and ultrasonic treatment is performed for 30 minutes to make it uniformly dispersed in water.

[0035] 2) Pre-activation: the montmorillonite slurry after ultrasonic treatment is pre-activated with cation exchange resin to obtain pre-activated montmorillonite.

[0036] 3) Load: prepare a slurry of pre-activated montmorillonite and deionized water in a ratio of 1:8, add a mixed solution of 0.05mol / L cerium nitrate solution and 0.03mol / L ferric nitrate solution, and heat to 80 Stir for 7 hours at °C.

[0037] 4) Centrifuging, roasting in a muffle furnace at 400°C for 1.5 hours, cooling and grinding to obtain the montmorillonite water purifying agent.

Embodiment 3

[0039] A preparation method of montmorillonite water purifying agent capable of adsorbing reactive dyes in water body, the method includes the following steps:

[0040] 1) Pulping: montmorillonite is added with deionized water to make a slurry, the slurry concentration reaches 25wt%, and ultrasonic treatment is performed for 30 minutes to make it uniformly dispersed in water.

[0041] 2) Pre-activation: the montmorillonite slurry after ultrasonic treatment is pre-activated with cation exchange resin to obtain pre-activated montmorillonite.

[0042] 3) Load: prepare a slurry of pre-activated montmorillonite and deionized water in a ratio of 1:8, add a mixed solution of 0.04mol / L lanthanum nitrate solution and 0.03mol / L ferric nitrate solution, and heat to 70 Stir for 8 hours at °C.

[0043] 4) Centrifuging, roasting in a muffle furnace at 400°C for 1.5 hours, cooling and grinding to obtain the montmorillonite water purifying agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com