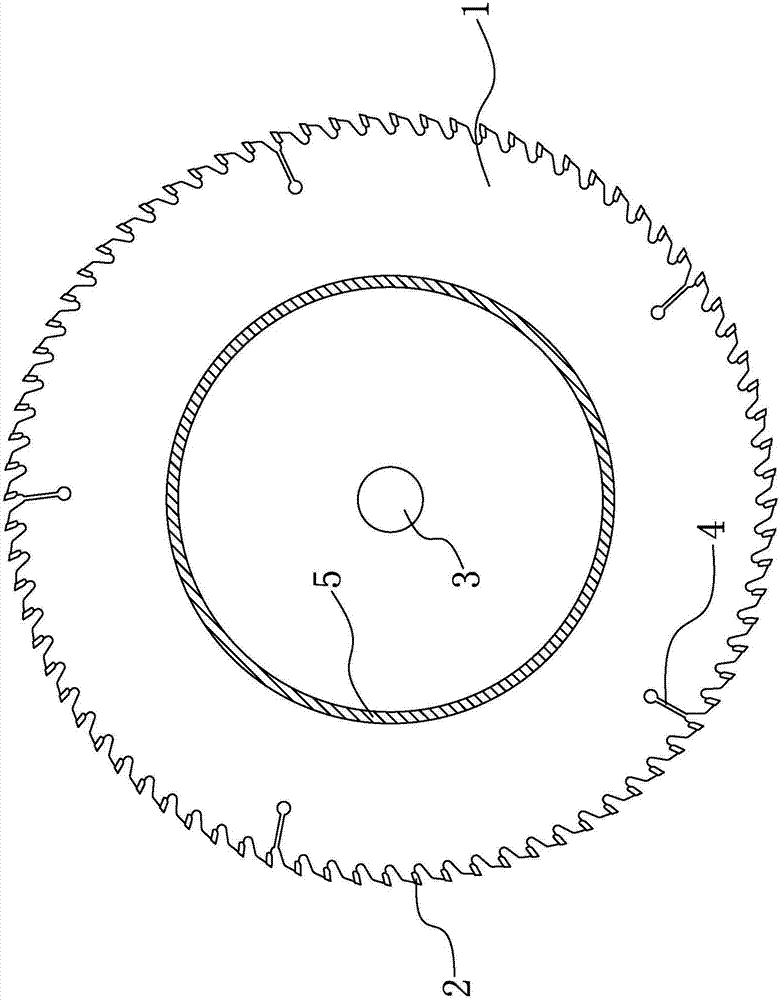

Hard alloy saw web

A technology of cemented carbide and cemented carbide substrate, which is applied in the direction of metal sawing equipment, metal processing equipment, sawing machine tools, etc., can solve the problems of affecting the service life and cutting effect of saw blades, destroying dynamic balance, changing, etc. Achieve narrow grain size distribution, good hardness and strength, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

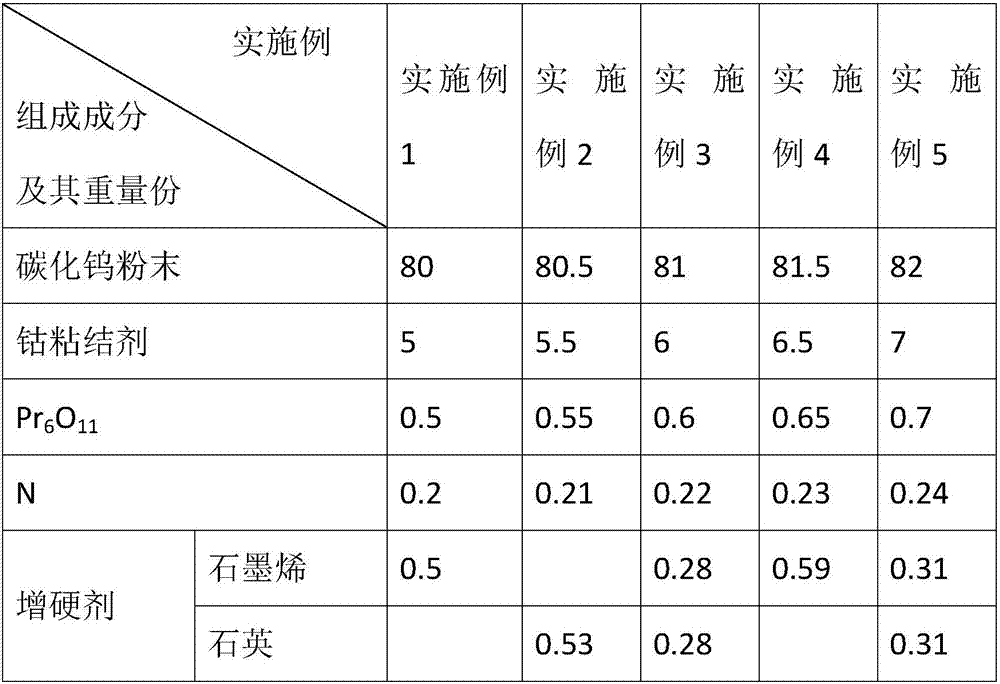

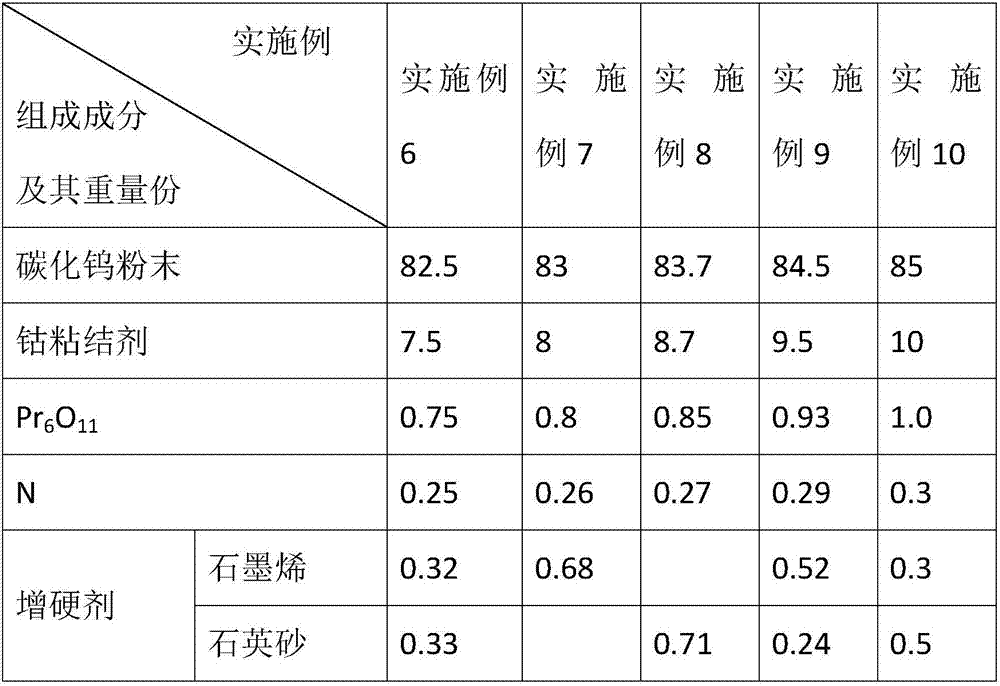

Examples

Embodiment 1

[0046] Mixing: take the cemented carbide material and add it to the ball mill according to the parts by weight described in Example 1 in Table 1, wherein the grain size of the tungsten carbide powder is 0.3 μm, and the cobalt binder contains 2% Cr and 0.2% Re, and add 200ml of D70 solvent oil for wet grinding until the powder particle size is 1 μm to obtain a mixed slurry. After the mixed slurry is filtered, dry it at 100°C for 30 minutes to obtain a mixture;

[0047] Compression molding: under the condition of a pressure of 30MPa, the mixture is respectively put into the saw blade base mold and the saw blade sawtooth mold for press molding to obtain the saw blade base blank and the saw blade sawtooth blank;

[0048] Sintering: Quenching the saw blade substrate blank and the saw tooth blank, the quenching temperature is 820°C, and the quenching time is 5 minutes; after quenching, sintering is carried out in a vacuum, the sintering temperature is 1300°C, and 0.02 % grain growth...

Embodiment 2

[0053] Mixing: take the cemented carbide material and add it to the ball mill according to the parts by weight described in Example 2 in Table 1, wherein the grain size of the tungsten carbide powder is 0.32 μm, and the cobalt binder contains 2.1% Cr and 0.23% Re, and add 210ml of D70 solvent oil for wet grinding until the powder particle size is 1.1μm to obtain a mixed slurry. After the mixed slurry is filtered, dry it at 102°C for 31min to obtain a mixture;

[0054] Compression molding: under the condition of a pressure of 32MPa, put the mixture into the saw blade base mold and the saw blade sawtooth mold respectively for press molding to obtain the saw blade base blank and the saw blade sawtooth blank;

[0055] Sintering: Quenching the saw blade base blank and saw blade sawtooth blank, the quenching temperature is 823°C, and the quenching time is 5.5 minutes; after quenching, sintering is carried out in vacuum, the sintering temperature is 1320°C, and 0.023 % grain growth i...

Embodiment 3

[0060] Mixing: take the cemented carbide material and add it to the ball mill according to the parts by weight described in Example 3 in Table 1, wherein the grain size of the tungsten carbide powder is 0.34 μm, and the cobalt binder contains 2.2% Cr and 0.26% Re, and add 220ml of D70 solvent oil for wet grinding until the powder particle size is 1.2μm to obtain a mixed slurry. After the mixed slurry is filtered, dry it at 104°C for 32min to obtain a mixture;

[0061] Compression molding: under the condition of a pressure of 34MPa, put the mixture into the saw blade base mold and the saw blade sawtooth mold respectively for press molding to obtain the saw blade base blank and the saw blade sawtooth blank;

[0062] Sintering: Quenching the saw blade substrate blank and the saw tooth blank, the quenching temperature is 826°C, and the quenching time is 6 minutes; after quenching, sintering is carried out in vacuum, the sintering temperature is 1340°C, and 0.026 % grain growth inh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com