Flame-retardant natural fiber composite board and preparation method thereof

A technology of natural fiber and composite board, applied in the direction of flame-retardant fiber, fiber type, fiber treatment, etc., can solve the problems of use limitation, increased material cost, complicated method, etc., to ensure stability, rich surface, uniform mesh surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

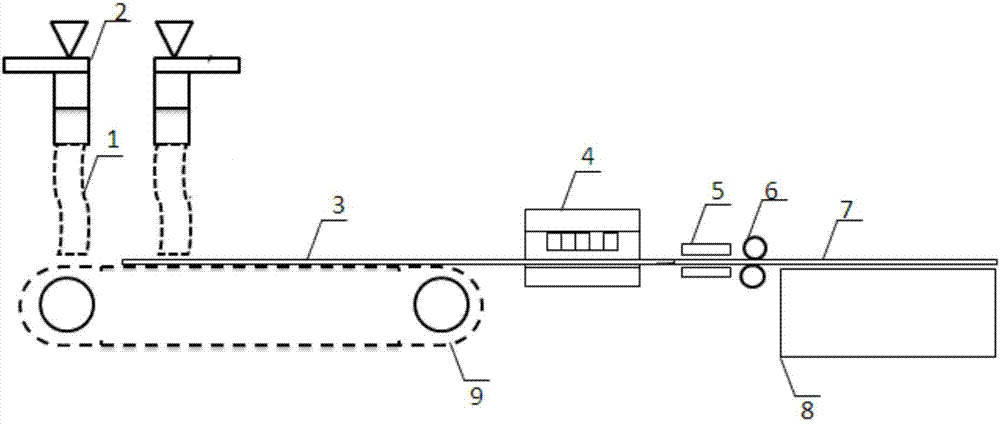

[0035] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the device used for processing the flame-retardant natural fiber composite board of the embodiment of the present invention.

[0036] 1. Mix coconut palm fiber treated with flame retardant monoammonium phosphate with flame-retardant ES short fiber, mix roughly, and put it into the silo, wherein the content of coconut palm fiber is 30 parts, and the content of flame-retardant ES short fiber is 70 copies;

[0037] 2. After the mixed fibers are opened, the carding machine 2 lays the net to form a mixed natural fiber thin net 1, that is, the coconut palm / ES mixed fiber thin net;

[0038] 3. After the above-mentioned mixed natural fiber thin net 1 is alternately laminated, a laminated natural fiber web 3 is formed, that is, a laminated coconut palm / ES fiber web, which is transported through the bottom curtain 9, and after passing through the acupuncture machine 4 , to be needle-punched into felt; ...

Embodiment 2

[0042] 1. Mix jute fiber treated with flame retardant diammonium phosphate and flame-retardant PP chopped fiber, after roughly mixing, put it into the feed bin, wherein the content of jute fiber is 35 parts, and the content of flame-retardant PP chopped fiber is 65 copies;

[0043] 2. After the mixed fibers are opened, the carding machine lays the net to form a jute / PP mixed fiber thin net;

[0044] 3. After the above-mentioned mixed natural fiber thin nets are alternately laminated, a laminated natural fiber net is formed, which is needled into a felt by a needle punching machine;

[0045] 4. Heat the needle-punched felt through a heating oven, and roll it with a hot-pressing roller. The rolling pressure is 0.3-1MPa to form a continuous flame-retardant jute / PP fiber composite sheet. The hot-pressing temperature range is 195-200°C;

[0046] 5. Cut the continuous flame-retardant jute / PP fiber composite board, and test the cut material.

Embodiment 3

[0048] 1. Mix the flax fiber and ramie fiber treated with the flame retardant dimethyl methyl phosphate with the flame retardant ES staple fiber, mix them roughly, and put them into the silo, wherein the flax fiber content is 20 parts, and the ramie fiber content 20 parts, flame retardant ES short fiber content is 60 parts;

[0049]2. After the mixed fibers are opened, the carding machine lays the net to form a flame-retardant flax / ramie / ES mixed fiber thin net

[0050] 3. After the above-mentioned flame-retardant flax / ramie / ES mixed fiber thin net is laid alternately, a laminated natural fiber net is formed, and the flame-retardant flax / ramie / ES mixed fiber composite felt is needled by a needle punching machine;

[0051] 4. Heat the needle-punched felt through a heating oven and roll it with a hot pressing roller. The rolling pressure is 0.3-1MPa to form a continuous flame-retardant flax / ramie / ES mixed fiber composite sheet. The hot-pressing temperature range is 180- 190°C; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com