Noise-reduction and fire-resistant brick and preparation method thereof

A refractory brick and sound-absorbing technology, applied in the field of refractory materials, can solve the problems that sound-absorbing agents cannot be used in refractory materials, etc., and achieve the effects of excellent thermal conductivity, cost saving for enterprises, and excellent tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

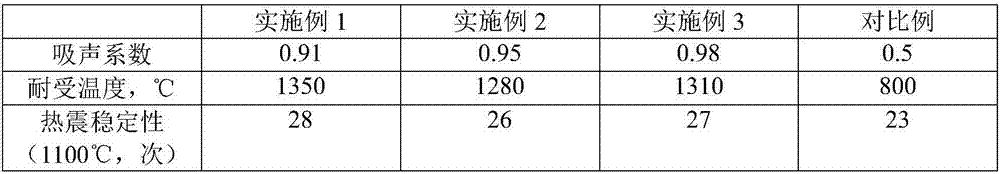

Examples

Embodiment 1

[0031] (1) Weigh according to the following proportions: 50g of fused magnesia sand, 5g of andalusite powder, and 10g of white carbon black are mixed in a mixer, and the mixture is evenly obtained to obtain granules;

[0032] (2) Weigh polysiloxane 0.1g, high-density polyethylene 0.3g, polyurethane 0.1g, biomass activated carbon fiber 0.03g, silicon micropowder (particle diameter2 / g) 0.005g, 0.005g of hollow microspheres (filled with epoxy acrylic resin) are made into 0.69g of silencer, weigh 2g of phenolic resin, and slowly add 2 / 3 of phenolic resin to the obtained product in step (1) Add the sound suppressing agent to the granular material, and finally add the remaining phenolic resin, and mix the material at 60°C for 30 minutes to obtain the mixture;

[0033] (3) The mixture obtained in step (2) is subjected to high-pressure molding, fired in a high-temperature tunnel kiln at 1400°C to 1600°C, kept for 6 hours, and cooled to obtain a sound-absorbing refractory brick.

Embodiment 2

[0035] (1) Weigh according to the following proportions: 60g of fused magnesia sand grains, 15g of andalusite powder, and 20g of white carbon black are mixed in a blender, and the mixture is uniform to obtain granules;

[0036] (2) Weigh 0.2g of polysiloxane, 0.4g of high-density polyethylene, 0.2g of polyurethane, 0.03g of biomass carbon molecular sieve, 0.06g of biomass-based activated carbon, 0.35g of silicon micropowder (particle size2 / g) 0.015g, hollow microspheres (filled with epoxy acrylic resin) 0.02g to make 1.275g of silencer, weigh 6g of phenolic resin, first slowly add 2 / 3 of phenolic resin to step (1) obtained Add the sound suppressing agent to the granular material, and finally add the remaining phenolic resin, and mix the material at 80°C for 20 minutes to obtain the mixture;

[0037] (3) The mixture obtained in step (2) is subjected to high-pressure molding, fired in a high-temperature tunnel kiln at 1400°C to 1600°C, kept for 8 hours, and cooled to obtain a so...

Embodiment 3

[0039] (1) Weighing according to the following proportioning: 55g of fused magnesia sand grains, 10g of andalusite powder, and 15g of white carbon black are mixed in a mixer, and the mixture is evenly obtained to obtain granules;

[0040](2) Weigh 0.15g of polysiloxane, 0.35g of high-density polyethylene, 0.15g of polyurethane, 0.06g of biomass-based activated carbon, 0.25g of silicon micropowder (particle diameter2 / g) 0.01g, hollow microspheres (filled with epoxy acrylic resin) 0.01g to make 0.98g of silencer, weigh 4g of phenolic resin, first slowly add 2 / 3 of phenolic resin to step (1) obtained Add the sound suppressing agent to the granular material, and finally add the remaining phenolic resin, and mix the material at 70°C for 25 minutes to obtain the mixture;

[0041] (3) The mixture obtained in step (2) is subjected to high-pressure molding, fired in a high-temperature tunnel kiln at 1400°C to 1600°C, kept for 7 hours, and cooled to obtain a sound-absorbing refractory b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com