PVC sole material and preparation method thereof

A technology of shoe sole materials and accelerators, applied in the field of shoe sole materials, can solve the problems of poor brittleness and flexibility, impact resistance, heat resistance, and poor light stability, so as to reduce the probability of fungal infection and improve insect resistance Effect, the effect of improving toughness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

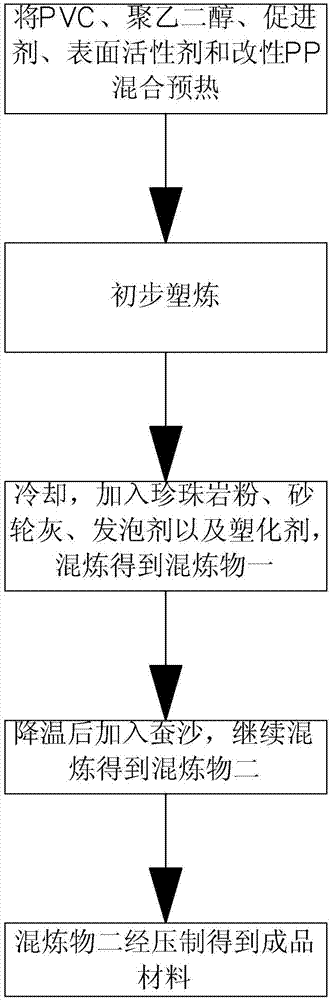

[0040] A preparation method for PVC sole material, comprising the following steps:

[0041] S1. Add 56Kg of PVC, 8Kg of polyethylene glycol, 2Kg of accelerator, 3Kg of surfactant and 12Kg of modified PP into the mixer for mixing, and heat up to 90-100°C for preheating to obtain a mixture;

[0042] S2. Transfer the mixture to a masticator for preliminary mastication, the temperature of mastication is 100-110°C, and the time lasts for 1.5-2.5 hours;

[0043] S3, resting the mixture after mastication for 3h, and making it gradually cool to room temperature;

[0044] S4, transfer 6Kg of perlite powder, 7Kg of grinding wheel ash, 12Kg of foaming agent and 4Kg of plasticizer and the cooled mixture to a mixer for mixing, the temperature is controlled at 160-180°C, and the time lasts for 0.5-1h to obtain Mixture one;

[0045] S5. Stop heating the mixture 1, and gradually lower the temperature of the mixture 1 while stirring continuously. When the temperature drops to 100°C, add 7Kg ...

Embodiment 2

[0049] A preparation method for PVC sole material, comprising the following steps:

[0050]S1. Add 62Kg of PVC, 12Kg of polyethylene glycol, 4Kg of accelerator, 7Kg of surfactant and 14Kg of modified PP into the mixer for mixing, and heat up to 90-100°C for preheating to obtain a mixture;

[0051] S2. Transfer the mixture to a masticator for preliminary mastication, the temperature of mastication is 100-110°C, and the time lasts for 1.5-2.5 hours;

[0052] S3, resting the mixture after mastication for 3h, and making it gradually cool to room temperature;

[0053] S4, transfer 14Kg of perlite powder, 13Kg of grinding wheel ash, 18Kg of foaming agent and 8Kg of plasticizer and the cooled mixture to a mixer for mixing, the temperature is controlled at 160-180°C, and the time lasts for 0.5-1h to obtain Mixture one;

[0054] S5. Stop heating the mixture 1, and gradually lower the temperature of the mixture 1 while stirring continuously. When the temperature drops to 100°C, add 15...

Embodiment 3

[0058] A preparation method for PVC sole material, comprising the following steps:

[0059] S1. Add 59Kg of PVC, 10Kg of polyethylene glycol, 3Kg of accelerator, 5Kg of surfactant and 13Kg of modified PP into the mixer for mixing, and heat up to 90-100°C for preheating to obtain a mixture;

[0060] S2. Transfer the mixture to a masticator for preliminary mastication, the temperature of mastication is 100-110°C, and the time lasts for 1.5-2.5 hours;

[0061] S3, resting the mixture after mastication for 3h, and making it gradually cool to room temperature;

[0062] S4, transfer 10Kg of perlite powder, 10Kg of grinding wheel ash, 15Kg of foaming agent and 6Kg of plasticizer and the cooled mixture to a mixer for mixing, the temperature is controlled at 160-180°C, and the time lasts for 0.5-1h to obtain Mixture one;

[0063] S5. Stop heating the mixture 1, and gradually lower the temperature of the mixture 1 while stirring continuously. When the temperature drops to 100°C, add 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com