Anti-oxidation polyvinyl chloride pipe and preparation method thereof

The technology of polyvinyl chloride and polyvinyl chloride resin is applied in the field of oxidation-resistant polyvinyl chloride pipes and their preparation, which can solve the problems of exudation of PVC monomers and additives, resistance to oxidation, cracking of pipes, etc., and reduce crystal structure defects. , Easy to process, prevent side cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

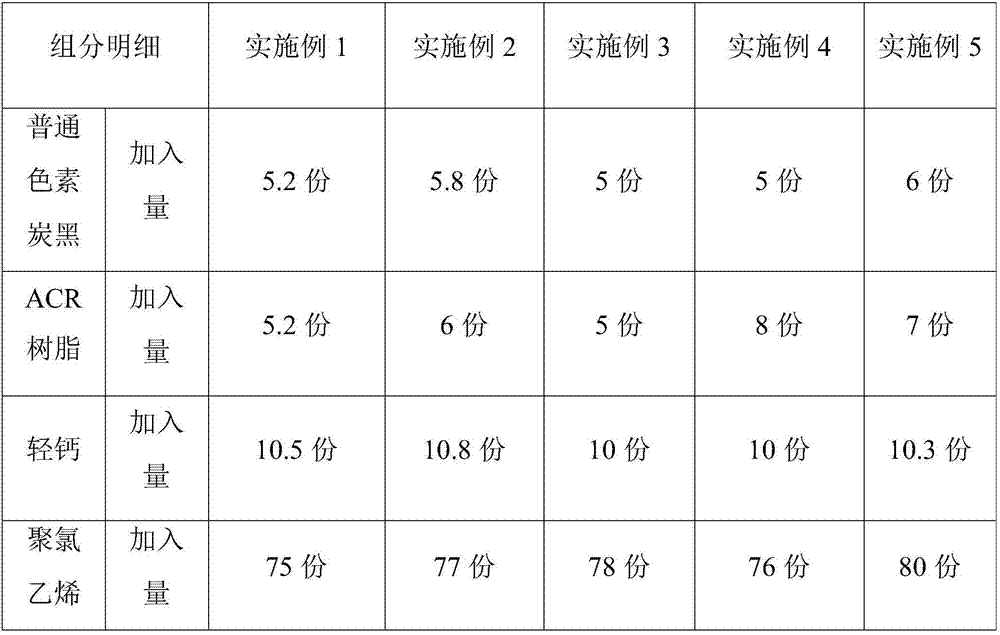

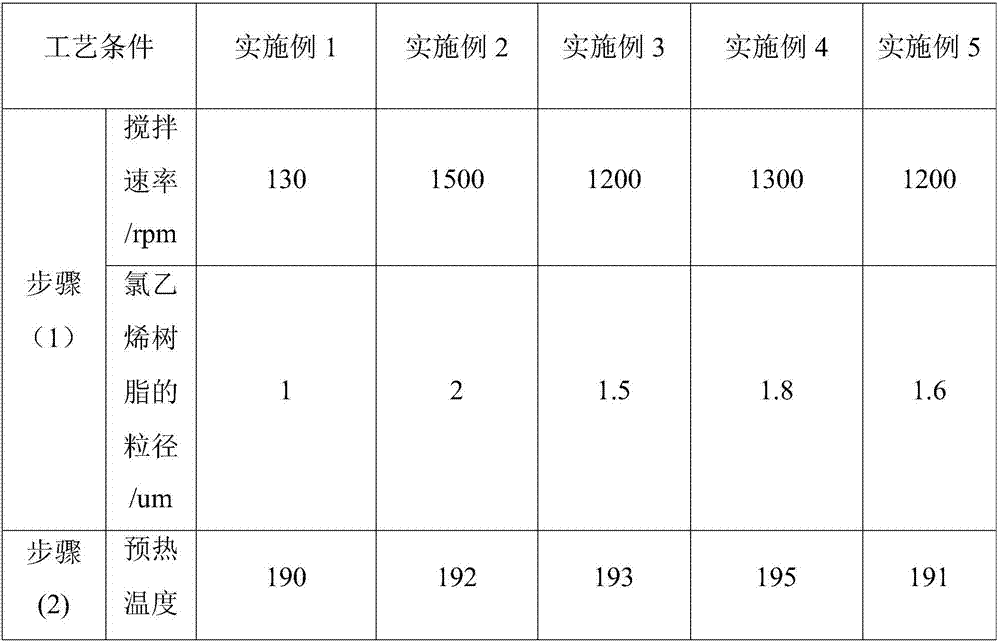

[0048] The invention provides an oxidation-resistant polyvinyl chloride pipe, which comprises the following components in parts by weight:

[0049] 75-80 parts of polyvinyl chloride resin;

[0050] 1-2 parts of plasticizer;

[0051] Composite antioxidant 0.5-1 part;

[0052] 5-6 parts of color enhancer;

[0053] 7-8 parts of lubricant;

[0054] 5-8 parts of ACR resin;

[0055] 10-11 parts of light calcium;

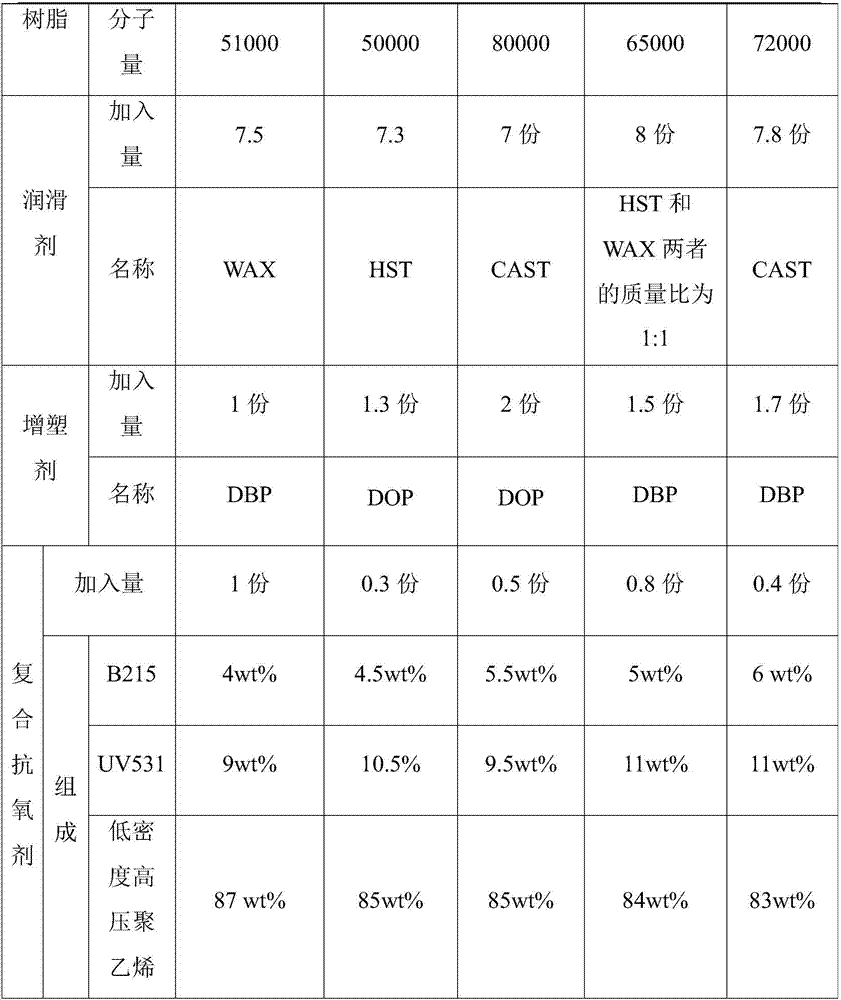

[0056] The composite antioxidant consists of:

[0057] Antioxidant B215 4-6wt%;

[0058]Anti-ultraviolet absorber UV531 9-12wt%;

[0059] Low-density high-pressure polyethylene: 82-87wt%.

[0060] Wherein, be common pigment carbon black; Sliding agent is one or more in WAX, HST or CAST; Described plasticizer dibutyl phthalate (DBP) or dioctyl phthalate (DOP) .

[0061] The details of the components corresponding to the oxidation-resistant polyvinyl chloride pipes of Examples 1-5 of the present invention are shown in Table 1 below.

[0062] Table 1 is a breakdown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com