Portable aviation cable fault test system

A technology of cable fault and testing system, which is applied in the direction of fault location, fault detection according to conductor type, fault detection by pulse reflection method, etc. It can solve the problems of difficult environmental noise, inconvenient communication, slow test speed, etc., and achieve the reduction of wrong disassembly The number of times, avoiding the reduction of cable life, and the effect of fast and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

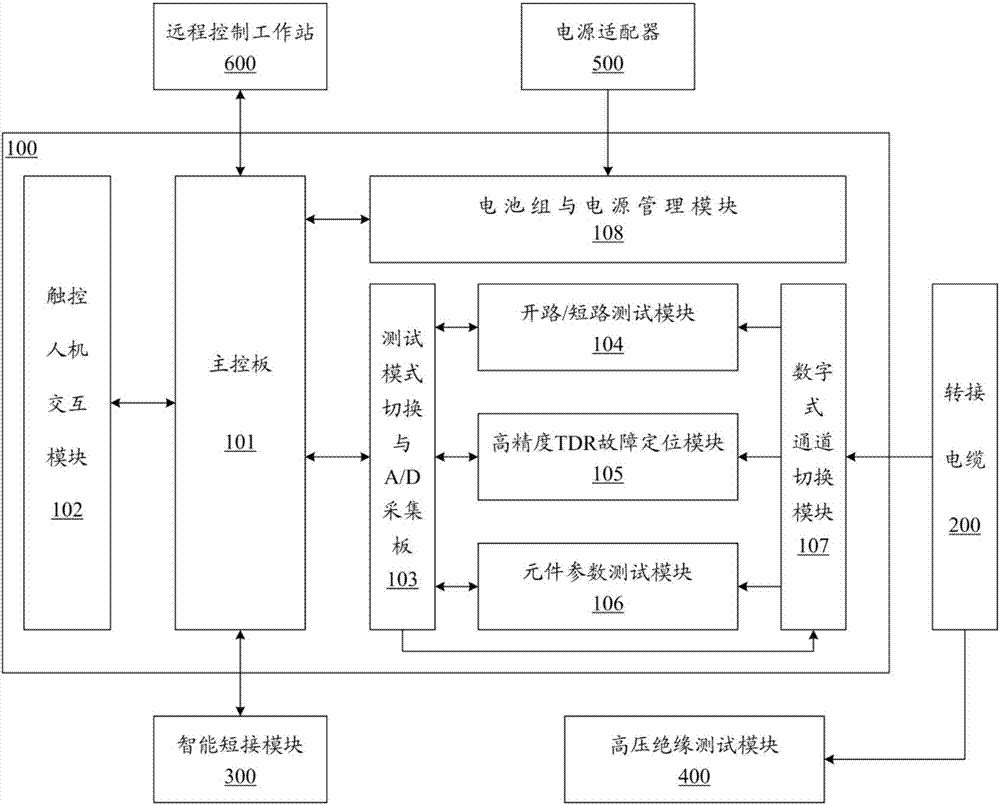

[0049] Please refer to figure 1As shown, it is a schematic structural diagram of the portable aviation cable fault testing system of the present invention. The test system includes: a host 100, an adapter cable 200, an intelligent short-circuit module 300, a high-voltage insulation test module 400, a power adapter 500, and a remote control workstation 600; the adapter cable 200, the intelligent short-circuit module 300, Both the power adapter 500 and the remote control workstation 600 are connected to the host 100, and the high voltage insulation test module 400 is connected to the adapter cable 200; wherein,

[0050] The host 100 is equipped with: a main control board 101, a touch human-computer interaction module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com